Mastering High-Frequency: The Rogers Substrate Advantage

Rogers Substrate plays a crucial role in modern electronic circuits, offering high-performance materials vital for various applications. From telecommunications to aerospace, Rogers Substrate ensures reliability and efficiency in electronic systems. In this discussion, we’ll delve into the essence of Rogers Substrate, exploring its composition, properties, and applications. We’ll compare it with FR4, another widely used substrate, highlighting key differences. Additionally, we’ll examine the materials used in Rogers Substrate and its popular 4000 series. Furthermore, we’ll explore real-world applications where Rogers Substrate excels, showcasing its versatility and importance in today’s technology-driven world.

What is Rogers Substrate?

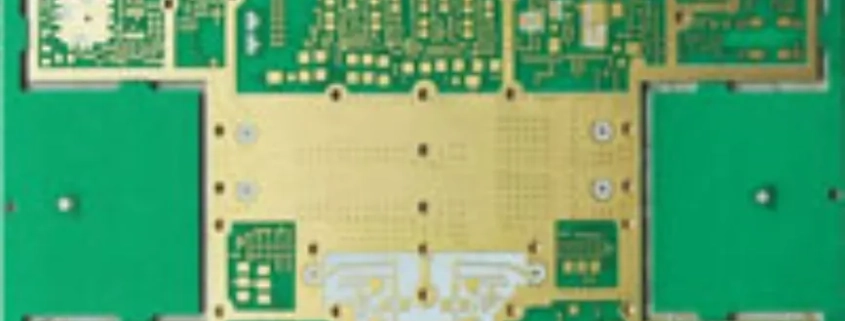

Rogers Substrate refers to a type of high-frequency laminate material used in the fabrication of printed circuit boards (PCBs). It is characterized by its exceptional electrical properties, such as low dielectric loss, consistent signal integrity, and high thermal stability. At its core, Rogers Substrate consists of a composite material composed of fiberglass reinforced with woven glass and impregnated with a thermosetting resin.

In the electronics industry, Rogers Substrate plays a pivotal role in ensuring the reliable performance of electronic devices and systems, particularly in high-frequency applications. Its ability to maintain signal integrity at high frequencies makes it indispensable in telecommunications, radar systems, satellite communication, automotive radar, and aerospace applications. By providing a stable platform for the transmission of radio frequency (RF) signals, Rogers Substrate enables the design and production of advanced electronic circuits with enhanced performance and efficiency. Moreover, its thermal stability ensures the longevity and reliability of electronic devices, even in harsh operating environments.

Overall, Rogers Substrate serves as a cornerstone in the electronics industry, facilitating the development of cutting-edge technologies and enabling the seamless integration of high-frequency circuits into a wide range of applications. Its importance cannot be overstated, as it continues to drive innovation and advancement in the field of electronics.

Difference Between Rogers Substrate and FR4

Rogers Substrate and FR4 are two widely used materials in the fabrication of printed circuit boards (PCBs), each offering distinct characteristics and performance capabilities.

- Characteristics and Performance

- Rogers Substrate:

- Rogers Substrate is known for its exceptional electrical properties, including low dielectric loss, high thermal stability, and excellent signal integrity retention at high frequencies.

- It typically exhibits a higher dielectric constant compared to FR4, making it suitable for high-frequency applications where precise impedance control is critical.

- Rogers Substrate is available in various formulations, such as the popular Rogers 4000 series, each tailored to specific frequency ranges and performance requirements.

- FR4:

- FR4, or Flame Retardant 4, is a widely used substrate material due to its affordability and versatility.

- It offers good mechanical strength and insulation properties, making it suitable for a wide range of applications, from consumer electronics to industrial equipment.

- FR4 has a lower dielectric constant compared to Rogers Substrate, which may result in higher signal attenuation at high frequencies.

- While FR4 is cost-effective and readily available, it may not provide the same level of performance as Rogers Substrate in high-frequency or high-speed applications.

- Rogers Substrate:

- Advantages and Disadvantages

- Rogers Substrate:

- Advantages:

- Excellent electrical properties, including low loss and high thermal stability.

- Superior signal integrity retention at high frequencies.

- Ideal for high-frequency applications such as telecommunications, radar systems, and aerospace.

- Disadvantages:

- Higher cost compared to FR4.

- Limited availability of specialized formulations for specific applications.

- Advantages:

- FR4:

- Advantages:

- Cost-effective and widely available.

- Good mechanical strength and insulation properties.

- Suitable for a wide range of applications, including consumer electronics and industrial equipment.

- Disadvantages:

- Limited performance at high frequencies compared to Rogers Substrate.

- Higher signal attenuation may affect performance in high-speed applications.

- Advantages:

- Rogers Substrate:

- Application Scenarios

- Rogers Substrate is preferred in high-frequency applications where precise signal integrity and impedance control are paramount, such as telecommunications, radar systems, and aerospace.

- FR4 is well-suited for general-purpose applications where cost-effectiveness and mechanical strength are more critical than high-frequency performance, such as consumer electronics, automotive electronics, and industrial control systems.

The choice between Rogers Substrate and FR4 depends on the specific requirements of the application, balancing factors such as performance, cost, and availability. While Rogers Substrate excels in high-frequency applications demanding superior electrical performance, FR4 remains a popular choice for general-purpose PCBs where cost-effectiveness and versatility are key considerations.

Materials of Rogers Substrate

Rogers Substrate utilizes advanced composite materials engineered to meet the demanding requirements of high-frequency electronic applications. These materials are carefully selected and optimized to achieve exceptional electrical performance while ensuring reliability and stability. Compared to FR4, Rogers Substrate offers distinct advantages in terms of electrical properties and performance.

- Characteristics and Performance

- Rogers Substrate:

- Rogers Substrate materials are formulated using specialized resin systems combined with ceramic fillers, such as PTFE (Polytetrafluoroethylene) or ceramic powders.

- These materials exhibit low dielectric loss, high thermal stability, and excellent dimensional stability over a wide temperature range, ensuring reliable performance in demanding environments.

- Rogers Substrate offers precise control over electrical properties, including dielectric constant (εr) and loss tangent (tanδ), enabling designers to achieve precise impedance matching and signal integrity.

- The materials are available in various formulations within the Rogers 4000 series, each tailored to specific frequency ranges and performance requirements.

- FR4:

- FR4 is a composite material composed of woven fiberglass cloth impregnated with epoxy resin.

- While FR4 offers good mechanical strength and insulation properties, its electrical performance is generally lower compared to Rogers Substrate.

- FR4 has a higher dielectric constant and higher loss tangent compared to Rogers Substrate, resulting in increased signal attenuation and reduced signal integrity at high frequencies.

- Rogers Substrate:

- Advantages and Disadvantages

- Rogers Substrate:

- Advantages:

- Exceptional electrical properties, including low dielectric loss and high thermal stability.

- Precise control over electrical parameters for optimized performance.

- Suitable for high-frequency applications requiring superior signal integrity and impedance control.

- Disadvantages:

- Higher cost compared to FR4.

- Limited availability of specialized formulations for specific applications.

- Advantages:

- FR4:

- Advantages:

- Cost-effective and widely available.

- Good mechanical strength and insulation properties.

- Suitable for general-purpose applications where high-frequency performance is not critical.

- Disadvantages:

- Lower electrical performance compared to Rogers Substrate.

- Increased signal attenuation and reduced signal integrity at high frequencies.

- Advantages:

- Rogers Substrate:

- Application Scenarios

- Rogers Substrate is preferred in high-frequency applications where precise signal integrity and impedance control are essential, such as telecommunications, radar systems, and aerospace.

- FR4 is suitable for general-purpose PCB applications where cost-effectiveness and mechanical strength are more critical than high-frequency performance, such as consumer electronics, automotive electronics, and industrial control systems.

The choice between Rogers Substrate and FR4 depends on the specific requirements of the application, considering factors such as performance, cost, and availability. While Rogers Substrate offers superior electrical performance for high-frequency applications, FR4 remains a cost-effective solution for general-purpose PCBs where high-frequency performance is not a primary concern.

Rogers 4000 Series

The Rogers 4000 series represents a family of high-performance laminates designed to meet the stringent demands of high-frequency electronic applications. This series encompasses a range of materials specifically engineered to provide exceptional electrical performance, reliability, and consistency. Let’s delve into the features and advantages of the Rogers 4000 series:

- Product Range: The Rogers 4000 series includes several laminate materials, each tailored to different frequency ranges and performance requirements. Some of the key products within this series include:

- RO4000® laminates: These laminates offer excellent electrical properties, thermal stability, and dimensional stability, making them ideal for high-frequency applications requiring precise signal integrity and impedance control.

- RO4350® laminates: Known for their low dielectric constant and low loss tangent, RO4350 laminates are suitable for high-speed digital and wireless communication applications.

- RO4835™ laminates: Designed for high-frequency applications requiring ultra-low loss, RO4835 laminates offer exceptional electrical performance and thermal stability.

- Features and Advantages:

- Low Loss: The Rogers 4000 series laminates are characterized by their low dielectric loss, allowing for minimal signal attenuation and superior signal integrity at high frequencies.

- High Thermal Stability: These laminates exhibit excellent thermal stability, maintaining their electrical properties over a wide temperature range. This ensures reliable performance in harsh operating environments.

- Precise Control over Electrical Properties: The Rogers 4000 series offers precise control over key electrical parameters such as dielectric constant (εr) and loss tangent (tanδ), enabling designers to achieve precise impedance matching and signal integrity.

- Dimensional Stability: These laminates demonstrate exceptional dimensional stability, reducing the risk of warpage or delamination during PCB fabrication and assembly processes.

- Consistency and Reliability: Rogers Substrate materials are known for their consistency and reliability, ensuring predictable performance from batch to batch and facilitating the production of high-quality PCBs.

The Rogers 4000 series represents a premier choice for high-frequency PCB applications, offering a comprehensive range of laminates with exceptional electrical performance, thermal stability, and reliability. Whether it’s telecommunications, radar systems, or aerospace applications, the Rogers 4000 series provides designers with the tools they need to push the boundaries of high-frequency technology while maintaining uncompromising quality and reliability.

Applications of Rogers Substrate

Rogers Substrate finds wide-ranging applications across various industries due to its exceptional electrical properties and reliability. Let’s explore some of the diverse fields where Rogers Substrate is extensively used:

- Telecommunications: Rogers Substrate is extensively utilized in telecommunications infrastructure, including base stations, antennas, and RF/microwave components. Its low dielectric loss and high thermal stability make it ideal for high-frequency signal transmission and reception, ensuring reliable communication networks.

- Aerospace and Defense: In the aerospace and defense sectors, Rogers Substrate is deployed in radar systems, satellite communication systems, avionics, and missile guidance systems. Its superior electrical performance and thermal stability enable the development of robust electronic systems capable of withstanding harsh environmental conditions.

- Automotive Electronics: Rogers Substrate is increasingly being incorporated into automotive electronics for applications such as collision avoidance systems, radar sensors, and vehicle-to-vehicle communication systems. Its high-frequency capabilities and reliability make it suitable for advanced driver assistance systems (ADAS) and autonomous driving technologies.

- Medical Devices: In the medical device industry, Rogers Substrate is used in devices such as MRI machines, medical imaging equipment, and implantable devices. Its high dielectric strength and biocompatibility ensure safe and reliable operation in medical applications where precision and reliability are paramount.

- Consumer Electronics: Rogers Substrate also finds applications in consumer electronics products, including smartphones, tablets, and wearable devices. Its ability to support high-speed data transmission and wireless communication technologies contributes to the performance and reliability of these devices.

Examples of successful projects utilizing Rogers Substrate

- 5G Base Stations: Rogers Substrate is extensively used in the construction of 5G base stations, where its low loss and high thermal stability enable the transmission of high-frequency signals over long distances, facilitating the rollout of high-speed 5G networks.

- Aircraft Radar Systems: Aircraft radar systems rely on Rogers Substrate for their signal processing and communication capabilities. The material’s exceptional electrical performance ensures accurate detection and tracking of objects in the aircraft’s vicinity, enhancing safety and situational awareness.

- Automotive Radar Sensors: Radar sensors in automotive applications utilize Rogers Substrate for their high-frequency performance and reliability. These sensors enable features such as adaptive cruise control, blind-spot detection, and collision avoidance, enhancing driver safety and convenience.

- Medical Imaging Equipment: Medical imaging equipment, such as MRI machines and CT scanners, utilize Rogers Substrate for their RF transmission and reception components. The material’s low loss and high dielectric strength contribute to the accuracy and reliability of medical diagnostics.

- Wireless Communication Devices: Wireless communication devices, including Wi-Fi routers, Bluetooth modules, and cellular base stations, leverage Rogers Substrate for their high-frequency signal transmission capabilities. The material enables seamless connectivity and high data throughput in wireless networks.

Rogers Substrate plays a critical role in enabling advanced technologies across a diverse range of industries, from telecommunications and aerospace to automotive electronics and medical devices. Its exceptional electrical properties and reliability make it indispensable for high-performance electronic systems, contributing to innovation and progress in various fields.

FAQs About Rogers substrate

Rogers substrate refers to a high-frequency laminate material used in the production of printed circuit boards (PCBs). It provides excellent electrical properties, thermal stability, and signal integrity, making it suitable for high-frequency applications in various industries.

Rogers substrate and FR4 are both materials used in PCB manufacturing, but they differ in their electrical properties and performance. Rogers substrate offers superior electrical characteristics, such as lower dielectric loss and higher thermal stability, compared to FR4. This makes Rogers substrate more suitable for high-frequency applications where precise signal integrity is crucial.

Rogers PCB is made of composite materials, typically consisting of fiberglass reinforced with woven glass and impregnated with a thermosetting resin. Additionally, Rogers PCB may incorporate specialized materials like PTFE (Polytetrafluoroethylene) or ceramic fillers to enhance its electrical properties.

Rogers 4000 material refers to a series of high-performance laminates developed by Rogers Corporation for high-frequency PCB applications. This series includes various formulations of laminates tailored to specific frequency ranges and performance requirements, offering excellent electrical performance, thermal stability, and reliability.