Rogers PCB and FR4: Exploring the Materials Frontier

In the field of electronic engineering, Printed Circuit Boards (PCBs) play a key role and are the key to seamless device functionality. In this technological landscape, the emergence of Rogers PCB marks a revolutionary breakthrough. Rogers PCBs stand out with their unique material composition, making them the first choice for applications requiring high-frequency accuracy and unwavering reliability. This blog explores Rogers PCB, revealing its origins, the intricacies of the material, and its profound impact on the canvas of PCB technology. Join us as we explore the intricacies of Rogers PCBs and learn how they are the cornerstone of advancing electronic engineering capabilities.

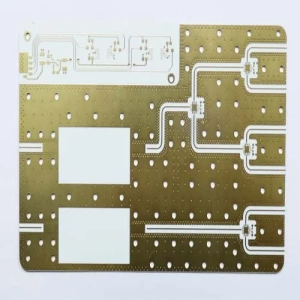

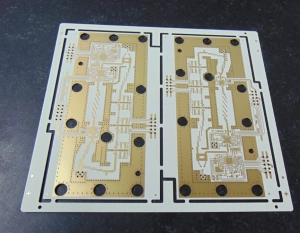

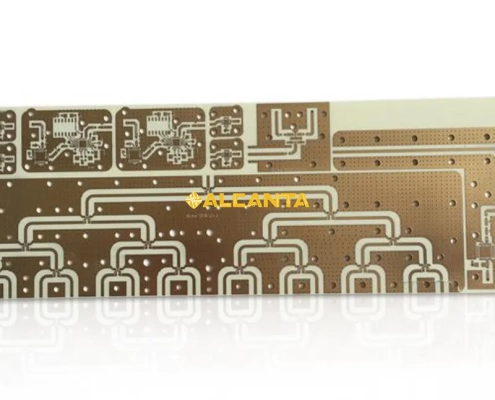

Rogers 4350B

Basic Concepts of Rogers PCB

What is Rogers PCB?

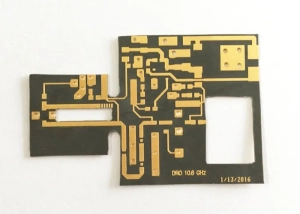

Rogers PCB, or Rogers Printed Circuit Board, is an advanced type of PCB known for its specialized material composition, which often includes ceramic-filled PTFE (Polytetrafluoroethylene). This composition imparts unique electrical and thermal properties to the board, making it particularly suitable for high-frequency applications. Rogers PCBs are meticulously engineered to meet the stringent demands of industries such as telecommunications, aerospace, and radar systems.

Difference between Rogers PCB and FR4 PCB

- Material Differences: The primary divergence between Rogers PCB and traditional FR4 PCB lies in their material composition. While FR4 PCBs utilize a substrate made of woven glass fiber reinforced with epoxy resin, Rogers PCBs incorporate a specialized dielectric material, such as RT/duroid or RO4003, enhancing their electrical performance.

- Performance Comparison: Rogers PCBs excel in high-frequency applications due to their lower dielectric constant, reduced signal loss, and improved thermal stability. In contrast, FR4 PCBs are more commonly used in standard applications where high-frequency precision is not critical. The superior electrical characteristics of Rogers PCBs make them ideal for advanced technologies like RF and microwave circuits, where signal integrity is paramount.

Understanding these material and performance distinctions is crucial for selecting the right PCB type based on the specific requirements of a given electronic system. As we delve deeper into the intricacies of Rogers PCB, we will explore how these differences contribute to its remarkable capabilities in diverse applications.

Rogers PCB Material Characteristics

Overview of Rogers PCB Materials

- Introduction to Rogers Corporation: Rogers PCB materials are crafted by the renowned Rogers Corporation, a global leader in advanced materials solutions. With a legacy of innovation, Rogers Corporation has been at the forefront of developing high-performance materials for various industries. In the realm of PCBs, their expertise translates into cutting-edge solutions that redefine the capabilities of electronic systems.

- Key Features of Rogers PCB Materials: Rogers PCB materials exhibit a range of exceptional features that set them apart. These include:

- Low Dielectric Loss: Rogers materials ensure minimal signal loss, crucial for high-frequency applications.

- Thermal Stability: The materials maintain their electrical properties across a wide temperature range, ensuring reliability in diverse environments.

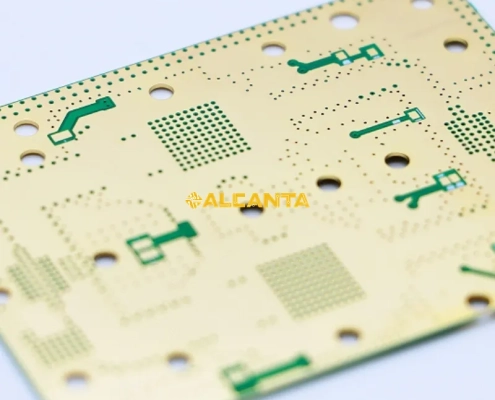

- Dimensional Stability: Rogers PCBs maintain consistent dimensions, vital for precision in manufacturing and performance.

Rogers PCB Material Datasheet

- In-depth Analysis of Rogers PCB Material Datasheet: Delving into the datasheet provides a comprehensive understanding of the material’s specifications, including thermal conductivity, dissipation factor, and mechanical properties. Engineers use this detailed information to tailor PCB designs to specific application requirements.

- Understanding Rogers PCB Material Properties: Rogers PCB materials possess unique properties that cater to the demands of high-frequency applications. These may include high glass transition temperatures, low moisture absorption, and excellent stability over a wide frequency range.

- Exploring Rogers PCB Material Dielectric Constant: The dielectric constant, or relative permittivity, is a crucial parameter defining the electrical characteristics of the material. Rogers PCB materials, with a lower dielectric constant compared to traditional substrates like FR4, contribute to reduced signal loss, making them ideal for high-frequency circuitry.

Understanding these material characteristics empowers engineers to make informed decisions when selecting PCB materials for specific applications. As we unravel the intricacies of Rogers PCB materials, we gain insights into how these features contribute to the exceptional performance of electronic systems.

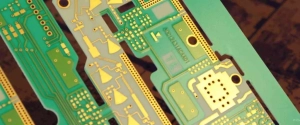

Manufacturing Process and Technology

Frequency Characteristics and Performance

Operating Frequency Range of Rogers PCB

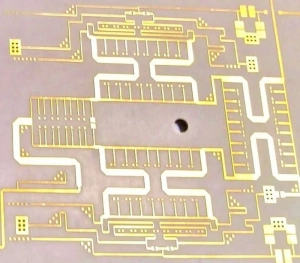

Rogers PCBs are engineered to thrive in high-frequency domains, boasting an impressive operating frequency range that exceeds the capabilities of traditional substrates. The precise range varies depending on the specific Rogers material employed, but generally spans from microwave frequencies up to several gigahertz. This makes Rogers PCBs the preferred choice for applications demanding superior signal integrity and performance at elevated frequencies.

Superior Performance of Rogers PCB in High-Frequency Applications

- Low Dielectric Loss: One of the defining features is the remarkably low dielectric loss of Rogers PCB materials. This characteristic ensures minimal signal attenuation even at high frequencies, making them indispensable in communication systems, radar technologies, and high-frequency RF circuits.

- Consistent Impedance Control: Rogers PCBs excel in maintaining consistent impedance, a critical factor in high-frequency designs. This stability ensures predictable signal propagation and minimal impedance mismatches, contributing to the reliability of complex electronic systems.

- Broadband Capabilities: Rogers materials exhibit broadband performance, enabling them to handle a wide spectrum of frequencies. This versatility positions Rogers PCBs as the backbone for applications ranging from wireless communication to aerospace systems, where a broad frequency range is imperative.

- Thermal Management: High-frequency applications often generate heat, and Rogers PCBs shine in thermal management. Their ability to dissipate heat efficiently ensures prolonged reliability under demanding operational conditions.

In essence, the superior performance of Rogers PCBs in high-frequency applications is a testament to the meticulous design and advanced material properties. As technology advances, Rogers PCBs remain at the forefront, continually pushing the boundaries of what is achievable in the realm of high-frequency electronic systems.

Cost and Feasibility

Pricing of Rogers PCB

The pricing of Rogers PCBs is influenced by several factors, including the specific Rogers material chosen, the complexity of the design, and the quantity ordered. Generally, Rogers PCBs tend to be more expensive than traditional FR4 counterparts due to the specialized materials and manufacturing processes involved. The unique electrical properties and high-frequency capabilities of Rogers PCBs contribute to their elevated cost, making it crucial for project managers and engineers to carefully evaluate the trade-off between performance and budget.

Cost Analysis of Rogers Substrate

- Material Costs: Rogers substrates, being proprietary and technologically advanced, can contribute significantly to the overall cost of PCB production. The specific composition and quality of the Rogers material selected directly impact the material costs.

- Manufacturing Processes: The precision required in the manufacturing processes, such as circuit imaging and lamination, contributes to the cost. Additionally, specialized equipment and expertise for handling Rogers materials add to the manufacturing expenses.

Feasibility Assessment of Rogers PCB in Real-world Projects

- Project Requirements: Assessing the feasibility of Rogers PCB involves aligning project requirements with the unique attributes of Rogers materials. Projects demanding high-frequency precision, thermal stability, and consistent performance often find Rogers PCBs indispensable, justifying the associated costs.

- Performance vs. Budget: Engineers and project managers must weigh the enhanced performance benefits of Rogers PCBs against budget constraints. In applications where signal integrity and reliability are paramount, the superior capabilities of Rogers PCBs may outweigh the additional costs.

- Industry Standards: Consideration of industry standards and regulations is crucial. In sectors like aerospace and telecommunications, where adherence to strict standards is imperative, the enhanced performance and reliability of Rogers PCBs may align well with project goals.

- Risk Mitigation: Evaluating the risks associated with project requirements and potential performance issues is essential. Rogers PCBs, with their proven track record in high-performance applications, often mitigate risks related to signal loss and thermal management.

The cost and feasibility of integrating Rogers PCBs into real-world projects necessitate a comprehensive evaluation of project requirements, performance expectations, and budget considerations. While Rogers PCBs may incur higher costs, their unique attributes position them as an indispensable solution for projects demanding cutting-edge performance.

FAQs About Rogers PCB

What is Rogers in PCB?

Rogers in PCB refers to Rogers Printed Circuit Boards, which utilize specialized materials from the Rogers Corporation, known for high-frequency applications.

What is the difference between Rogers and FR4?

Rogers differs from FR4 in material composition. Rogers PCBs use advanced materials like ceramic-filled PTFE, offering superior high-frequency performance compared to FR4, which uses woven glass fiber reinforced with epoxy resin.

What is the frequency of Rogers PCB?

The frequency of Rogers PCBs varies based on the specific material used but generally spans from microwave frequencies up to several gigahertz, making them ideal for high-frequency applications.

What is the dielectric constant of Rogers?

The dielectric constant of Rogers PCB materials is typically lower than that of traditional substrates like FR4. Specific values depend on the Rogers material chosen but generally range from 2.2 to 10.

What is Rogers in PCB?

Rogers in PCB refers to the use of Rogers Corporation’s specialized materials in Printed Circuit Boards, providing enhanced performance characteristics crucial for high-frequency applications.

What is the difference between Rogers and FR4?

The primary difference lies in material composition. Rogers PCBs use advanced dielectric materials, providing better performance at high frequencies, while FR4 relies on woven glass fiber and epoxy resin.

What is the frequency of Rogers PCB?

The frequency of Rogers PCBs varies but generally covers a broad range, making them suitable for high-frequency applications where signal integrity is critical.