Comparing Materials: Rogers 6002 vs. Duroid Alternatives

Rogers Corporation, a global leader in advanced materials, pioneers innovations that drive progress in diverse industries. With decades of expertise, Rogers has earned a reputation for excellence in developing cutting-edge materials for high-performance applications. Among its renowned offerings, Rogers 6002 laminate stands out as a pinnacle of quality and reliability.

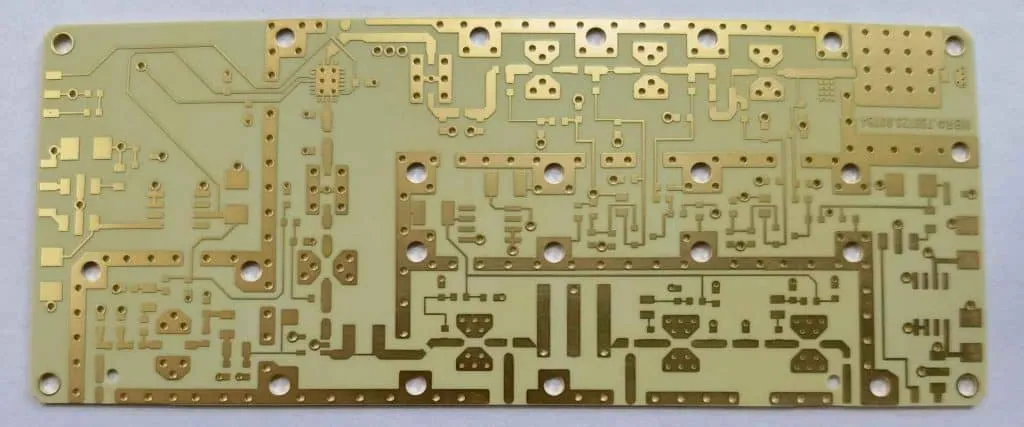

Understanding Rogers 6002

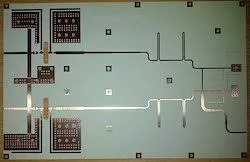

Rogers 6002 laminate is a high-frequency material renowned for its exceptional performance and reliability in electronic applications. Composed of woven fiberglass reinforcement and polytetrafluoroethylene (PTFE) dielectric, Rogers 6002 offers outstanding electrical properties and mechanical stability. Its low loss tangent and high thermal conductivity make it ideal for high-frequency circuitry requiring minimal signal distortion and efficient heat dissipation.

Key Properties of Rogers 6002:

- Low dielectric constant (εr) for improved signal integrity.

- Low loss tangent (Df) for minimal signal attenuation.

- Excellent dimensional stability for precise circuit fabrication.

- High thermal conductivity for efficient heat dissipation.

- Superior chemical resistance and reliability in harsh environments.

Comparison with Other Rogers Laminates:

- Rogers 5870: While both Rogers 6002 and 5870 offer low dielectric constants and loss tangents, 6002 boasts higher thermal conductivity, making it suitable for applications requiring enhanced heat dissipation.

- Rogers 6010: Rogers 6002 and 6010 share similar dielectric properties, but 6002 offers superior thermal conductivity, making it preferable for high-power applications.

- Rogers 6202: Rogers 6202 offers comparable electrical properties to 6002 but features a lower thermal conductivity, making it suitable for applications where heat dissipation is less critical.

Overall, Rogers 6002 stands out as a top choice for high-frequency circuitry, offering a unique combination of electrical performance, mechanical stability, and thermal management capabilities unmatched by other laminates in the Rogers portfolio.

Exploring the Applications of Rogers 6002: Unmatched Versatility and Performance

Real-World Applications

Rogers 6002 laminate finds extensive utilization across various industries, thanks to its exceptional properties and reliability. Here are some key areas where Rogers 6002 excels:

- Telecommunications: In the telecommunications sector, Rogers 6002 is a preferred choice for high-frequency circuitry in antennas, amplifiers, and transceivers. Its low loss tangent and high thermal conductivity ensure efficient signal transmission and reliable operation in demanding environments.

- Aerospace and Defense: In aerospace and defense applications, where reliability and performance are paramount, Rogers 6002 shines. It is used in radar systems, satellite communications, and avionics, delivering unparalleled signal integrity and durability under extreme conditions.

- Automotive Electronics: With the automotive industry’s increasing focus on connectivity and safety, Rogers 6002 plays a crucial role in advanced driver assistance systems (ADAS), radar sensors, and vehicle-to-vehicle communication. Its robust construction and thermal management capabilities make it ideal for automotive electronics.

- Medical Devices: Rogers 6002 is also utilized in medical devices, such as MRI machines, ultrasound equipment, and wireless telemetry systems. Its low loss tangent ensures accurate signal transmission, while its dimensional stability guarantees precise circuit fabrication essential for medical diagnostics and treatment.

Case Studies and Examples:

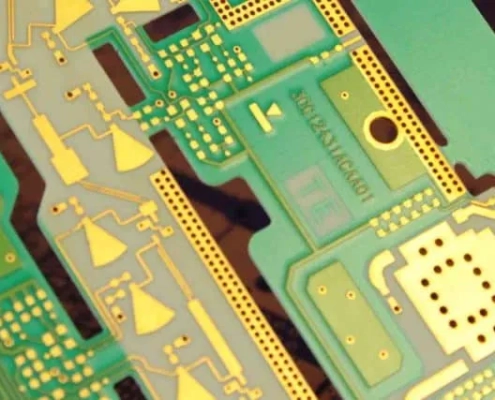

- 5G Infrastructure: In the rollout of 5G networks, Rogers 6002 laminates are extensively used in base stations, antennas, and RF modules. Case studies have shown that the use of Rogers 6002 contributes to the reliability and performance of 5G infrastructure, enabling faster data transmission and expanded network coverage.

- Satellite Communications: Satellite communication systems rely on Rogers 6002 for their critical components. Case studies have demonstrated the reliability of Rogers 6002 in satellite transponders and receivers, ensuring uninterrupted communication links between satellites and ground stations, even in challenging space environments.

- High-Performance Radar Systems: Radar systems in military and civilian applications benefit from Rogers 6002’s superior electrical properties and thermal stability. Case studies have highlighted its role in high-resolution imaging radars and weather monitoring systems, where accuracy and reliability are essential for mission success.

- Wireless Medical Devices: In wireless medical devices such as wearable monitors and implantable sensors, Rogers 6002 provides the necessary signal integrity and reliability. Case studies have showcased its use in continuous glucose monitoring systems and cardiac monitoring devices, where precise data transmission is critical for patient health monitoring.

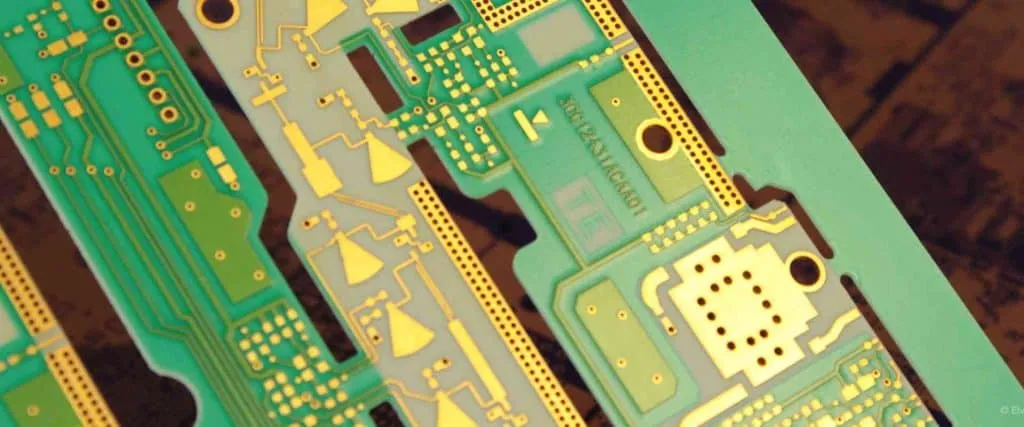

Rogers 6002 demonstrates unparalleled versatility and performance across a wide range of applications, making it the material of choice for demanding electronic designs in telecommunications, aerospace, automotive, medical, and other industries. Case studies and examples underscore its role in driving innovation and advancing technology in these critical sectors.

Detailed Analysis

Rogers 6002 laminate is characterized by several performance specifications crucial for its application in high-frequency electronic designs. Let’s delve into these specifications and their significance:

- Dielectric Constant (εr): The dielectric constant of Rogers 6002 typically ranges from 2.94 to 2.96 at 10 GHz. This low dielectric constant indicates the material’s ability to support high-frequency signals with minimal signal loss. It ensures efficient signal transmission and impedance matching in RF and microwave circuits.

- Loss Tangent (Df): Rogers 6002 boasts an exceptionally low loss tangent, typically ranging from 0.0013 to 0.0015 at 10 GHz. This parameter quantifies the material’s dissipation of electromagnetic energy as heat. A low loss tangent indicates minimal signal attenuation, preserving signal strength and fidelity in high-frequency applications.

- Thermal Conductivity: Rogers 6002 exhibits high thermal conductivity, typically around 0.60 W/m·K. This property enables efficient heat dissipation from electronic components, preventing overheating and ensuring reliable operation, particularly in high-power applications.

Impact on Circuit Design and Performance

- Signal Integrity: The low dielectric constant and loss tangent of Rogers 6002 contribute to excellent signal integrity by minimizing signal distortion and attenuation. This ensures accurate data transmission and reliable communication in high-frequency circuits.

- Impedance Matching: The consistent dielectric constant of Rogers 6002 facilitates precise impedance matching in RF and microwave circuits, optimizing power transfer and reducing signal reflections. This is crucial for maximizing the efficiency and performance of electronic systems.

- Thermal Management: The high thermal conductivity of Rogers 6002 enhances thermal management in electronic devices by efficiently dissipating heat generated during operation. This helps maintain component reliability and extends the lifespan of critical electronic components.

- Dimensional Stability: The dimensional stability of Rogers 6002 ensures precise fabrication of circuits with minimal variation in electrical properties. This is essential for maintaining signal integrity and meeting tight tolerances in high-frequency designs.

The performance specifications of Rogers 6002, including its low dielectric constant, loss tangent, and high thermal conductivity, play a pivotal role in optimizing circuit design and performance. By providing excellent signal integrity, impedance matching, and thermal management capabilities, Rogers 6002 empowers engineers to develop high-performance electronic systems for a wide range of applications.

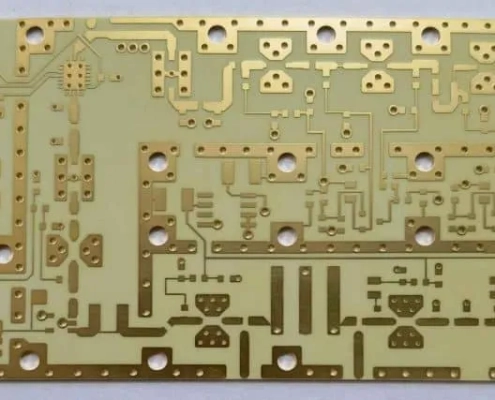

When designing circuits with Rogers 6002, several important considerations must be taken into account to maximize performance and reliability. Let’s explore these considerations and provide tips for optimizing the design:

1. Substrate Thickness

- Ensure proper selection of substrate thickness based on the desired electrical performance and mechanical stability. Thicker substrates may offer better dimensional stability but can increase signal loss, while thinner substrates may be more prone to mechanical deformation.

2. Trace Width and Spacing

- Optimize trace width and spacing to maintain controlled impedance and minimize signal loss. Consider the frequency of operation and impedance requirements of the circuit when determining these parameters.

3. Via Placement and Design

- Proper via placement and design are critical for maintaining signal integrity and minimizing signal reflections. Use through-hole vias or blind vias where necessary to transition between different layers while minimizing impedance mismatch.

4. Thermal Management

- Implement effective thermal management strategies to dissipate heat generated by high-power components. Ensure proper placement of heat sinks, vias, and thermal pads to enhance heat transfer away from critical components.

5. Material Handling and Fabrication

- Follow recommended material handling and fabrication techniques to prevent contamination and ensure consistent electrical properties. Avoid excessive bending or flexing of the substrate during manufacturing to maintain dimensional stability.

Tips for Optimizing Performance and Reliability

- Simulation and Prototyping: Utilize electromagnetic simulation tools to analyze the performance of the circuit and identify potential issues before fabrication. Prototype and test the design to validate its performance under real-world conditions.

- Optimized Grounding: Implement a robust grounding scheme to minimize ground loops and reduce electromagnetic interference (EMI). Use dedicated ground planes and strategically placed ground vias to enhance signal integrity.

- Signal Integrity Analysis: Conduct signal integrity analysis to identify and mitigate impedance mismatches, reflections, and crosstalk. Pay attention to signal transition times and rise/fall times to ensure proper signal propagation.

- Thermal Analysis: Perform thermal analysis to evaluate the temperature distribution within the circuit and identify hotspots. Adjust the layout and thermal management strategies accordingly to prevent overheating and ensure long-term reliability.

- Compliance with Industry Standards: Ensure compliance with relevant industry standards and regulations to guarantee the reliability and safety of the electronic system. Adhere to best practices and guidelines established by regulatory bodies and industry associations.

By incorporating these design considerations and optimization tips, engineers can harness the full potential of Rogers 6002 laminate, ensuring optimal performance, reliability, and longevity of electronic circuits in diverse applications.

Get a Quote Now

FAQs About Rogers 6002

What is Rogers 6002 laminate?

Rogers 6002 laminate is a high-frequency material known for its exceptional performance and reliability in electronic applications.

What are the key properties of Rogers 6002?

Key properties of Rogers 6002 include low dielectric constant, low loss tangent, high thermal conductivity, and excellent dimensional stability.

What are the typical applications of Rogers 6002?

Rogers 6002 is commonly used in telecommunications, aerospace, automotive electronics, and medical devices for high-frequency circuitry.

How does Rogers 6002 compare to other laminates?

Rogers 6002 offers superior thermal conductivity and signal integrity compared to many other laminates, making it ideal for demanding applications.

What are the benefits of using Rogers 6002 in electronic designs?

Using Rogers 6002 can lead to enhanced performance, reliability, and thermal management in electronic circuits.

How does the dielectric constant of Rogers 6002 affect circuit performance?

The low dielectric constant of Rogers 6002 ensures minimal signal loss and superior signal integrity in high-frequency circuits.

What considerations should be made when designing with Rogers 6002?

Designers should consider substrate thickness, trace width and spacing, via placement, thermal management, and material handling for optimal performance.

Is Rogers 6002 suitable for high-frequency applications?

Yes, Rogers 6002 is highly suitable for high-frequency applications due to its low loss tangent and excellent signal integrity.

How does Rogers 6002 contribute to thermal management in electronic circuits?

Rogers 6002’s high thermal conductivity helps dissipate heat generated by electronic components, contributing to efficient thermal management.

Where can I find technical specifications and datasheets for Rogers 6002?