Rogers 5870: The Material of Choice for High-Frequency Circuits

In today’s rapidly advancing technological landscape, the importance of Rogers 5870 cannot be overstated. As a high-performance electronic material, it stands at the forefront of innovation, enabling the development of cutting-edge solutions across various industries. This blog aims to provide an in-depth exploration of Rogers 5870, covering its technical specifications, real-world application examples, comparative analysis with competing products, insights into its production processes, and projections for future development trends. By delving into these aspects, readers will gain a comprehensive understanding of the capabilities and potential of Rogers 5870 in driving forward technological progress and meeting the demands of modern electronics applications.

Overview of Rogers Corporation

Technical Specifications and Characteristics of Rogers 5870

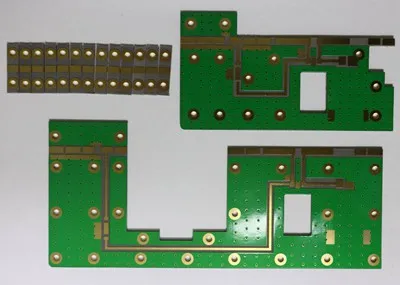

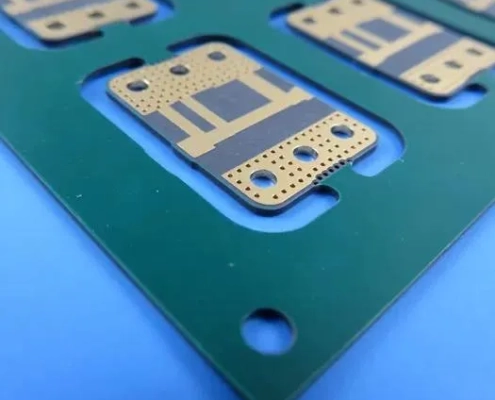

Application Examples of Rogers 5870

Comparison with Competing Products

When comparing Rogers 5870 with similar materials or competing products, several factors come into play, including dielectric constant, thermal stability, mechanical properties, and cost-effectiveness. Let’s analyze its relative advantages, disadvantages, and suitability for different application scenarios:

- Dielectric Constant:

- Rogers 5870 typically has a lower dielectric constant compared to some competing materials, resulting in lower signal loss and improved signal integrity in high-frequency circuits.

- Thermal Stability:

- Rogers 5870 offers excellent thermal stability with a high glass transition temperature (Tg), ensuring consistent performance over a wide temperature range. Some competing materials may exhibit lower thermal stability, leading to performance degradation under elevated temperatures.

- Mechanical Properties:

- Rogers 5870 demonstrates good dimensional stability and mechanical strength, making it suitable for applications requiring precise tolerances and durability. In contrast, some competing materials may have inferior mechanical properties, leading to issues such as warping or delamination.

- Cost-Effectiveness:

- While Rogers 5870 provides superior performance, it may come at a higher cost compared to some competing materials. However, its long-term reliability and performance may justify the initial investment in certain applications where quality is paramount.

- Suitability for Different Application Scenarios:

- In communication base stations, radar systems, and satellite communication, Rogers 5870’s low loss, high thermal stability, and dimensional stability offer significant advantages, ensuring reliable signal transmission and processing.

- In automotive radar systems, where reliability and performance are critical for collision avoidance and autonomous driving, Rogers 5870’s superior characteristics make it a preferred choice over competing materials.

- In aerospace applications, such as aircraft radar systems and satellite payloads, Rogers 5870’s ability to withstand extreme temperatures and harsh environmental conditions ensures continuous operation in demanding environments.

Overall, while Rogers 5870 may have a higher initial cost compared to some competing products, its superior performance, reliability, and suitability for critical applications make it a preferred choice in various high-frequency circuit design scenarios. However, the selection of the most suitable material ultimately depends on the specific requirements and priorities of each application.

Production Processes and Quality Control of Rogers 5870

The production process of Rogers 5870 involves several critical stages, each meticulously executed to ensure the material meets stringent quality standards:

- Material Preparation:

- The process begins with the careful selection and preparation of raw materials, including specialized resins, reinforcements, and additives.

- These materials are precisely measured and blended to achieve the desired composition and properties, such as dielectric constant and thermal stability.

- Molding:

- The prepared material is then subjected to molding processes, where it is shaped into thin sheets or panels of uniform thickness.

- Advanced molding techniques, such as compression molding or extrusion, are employed to ensure precise control over the final dimensions and properties of the material.

- Processing Stages:

- After molding, the material undergoes various processing stages, including curing, post-curing, and surface treatment.

- These stages are critical for enhancing the material’s mechanical strength, thermal stability, and surface finish, ensuring it meets the performance requirements of demanding applications.

Rogers Corporation implements rigorous quality control measures throughout the production process to uphold the highest standards of product quality and consistency:

- Material Testing:

- Raw materials undergo thorough testing and inspection to verify their quality and suitability for use in Rogers 5870 production.

- This includes testing for physical properties, chemical composition, and adherence to strict performance specifications.

- In-process Inspection:

- Throughout the production process, material properties, dimensions, and tolerances are continuously monitored and inspected to identify any deviations from quality standards.

- This proactive approach allows for prompt corrective action to be taken, ensuring that any potential issues are addressed before they impact the final product.

- Final Product Testing:

- Finished Rogers 5870 products undergo comprehensive testing to validate their performance and quality.

- This includes testing for electrical properties, thermal stability, mechanical strength, and dimensional accuracy, among others.

- Certification and Compliance:

- Rogers Corporation maintains certifications and compliance with industry standards and regulations, ensuring that Rogers 5870 products meet or exceed all relevant requirements.

- This commitment to certification and compliance further underscores the company’s dedication to delivering reliable and high-quality materials to its customers.

By adhering to strict quality control measures at every stage of production, Rogers Corporation ensures that Rogers 5870 products consistently meet the exacting standards demanded by its customers across various industries.

Future Development Trends of Rogers 5870

FAQs About Rogers 5870

What is Rogers 5870 material?

Rogers 5870 is a high-performance electronic material, known for its low dielectric constant, excellent thermal stability, and dimensional consistency.

What is the dielectric constant of Rogers 5870?

The dielectric constant of Rogers 5870 typically ranges from around 2.33 to 2.40 at 10 GHz.

How thick is Rogers 5880 substrate?

The thickness of Rogers 5880 substrate varies depending on the specific application and requirements, but it typically ranges from 0.0035 inches to 0.020 inches (approximately 0.089 mm to 0.508 mm).

What is the dielectric constant of RT Duroid 5880 substrate?

The dielectric constant of RT Duroid 5880 substrate is typically around 2.20 at 10 GHz.

Can Rogers 5870 be used in high-frequency circuit design?

Yes, Rogers 5870 is commonly used in high-frequency circuit design due to its low dielectric constant and excellent signal integrity properties.

What are the advantages of using Rogers 5870 in communication systems?

Rogers 5870 offers minimal signal loss, high thermal stability, and dimensional consistency, making it ideal for communication systems where reliable signal transmission is crucial.

How does the thickness of Rogers 5870 substrate impact its performance?

The thickness of Rogers 5870 substrate can affect its electrical properties and mechanical strength. Thinner substrates may offer better high-frequency performance but could be more prone to mechanical damage.

Is Rogers 5870 suitable for applications requiring high thermal stability?

Yes, Rogers 5870 demonstrates excellent thermal stability with a high glass transition temperature (Tg), making it suitable for applications where temperature fluctuations are common.

What industries commonly use Rogers 5870 in their products?

Industries such as telecommunications, aerospace, automotive, and healthcare commonly use Rogers 5870 in products such as communication base stations, radar systems, and medical devices.

What quality control measures does Rogers Corporation employ to ensure the reliability of Rogers 5870?

Rogers Corporation implements rigorous quality control measures throughout the production process, including material testing, in-process inspection, and final product testing, to ensure Rogers 5870 meets stringent quality standards.