Essential Materials for High-Performance Probe Card Substrates

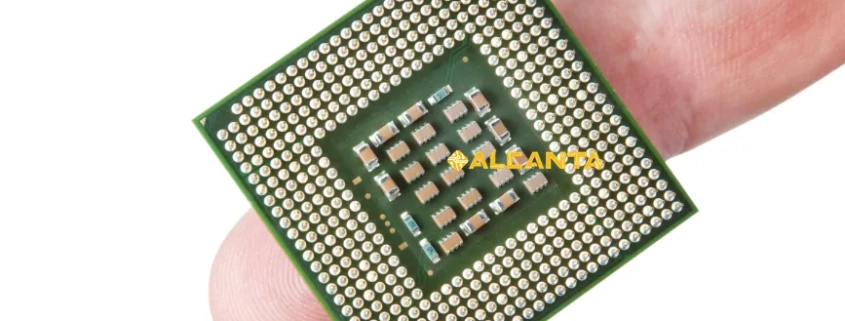

Probe cards are crucial components in semiconductor testing, serving as the interface between the test equipment and the semiconductor devices under evaluation. They are designed to make electrical contact with the device’s pins or pads, enabling the assessment of its functionality, performance, and quality. The accuracy and reliability of these tests heavily depend on the quality of the probe card substrate materials. Choosing the right materials for the substrate is essential, as it affects the probe card’s electrical performance, durability, and overall testing precision. High-quality substrates ensure stable electrical connections, reduce signal interference, and provide consistency in testing results, which is vital for the production of reliable semiconductor components.

What Materials Are Used to Make a Probe Card?

Substrate Materials

Probe card substrates are typically made from materials that offer a balance between mechanical stability, electrical performance, and thermal management. Common substrate materials include:

– FR4: A widely used epoxy fiberglass laminate, FR4 provides a cost-effective solution with good electrical insulation and mechanical strength. It is suitable for less demanding applications where high-frequency performance is not critical.

– Ceramics: Ceramic substrates, such as alumina or beryllium oxide, offer superior thermal conductivity and electrical insulation. They are preferred for high-frequency and high-power applications due to their stability and ability to handle thermal stresses.

– Specialized Composite Materials: Advanced composite materials are engineered to meet specific performance criteria, such as low thermal expansion and high thermal conductivity. These materials help to enhance the probe card’s performance in demanding environments.

Probing Materials

The materials used for the probe pins are selected for their electrical conductivity and durability. Key probing materials include:

– Tungsten: Known for its high melting point and strength, tungsten is commonly used for probe pins that require robust mechanical properties and reliable electrical contact.

– Gold: Gold is utilized for its excellent electrical conductivity and resistance to oxidation. It is often used in applications where a reliable and low-resistance contact is critical.

– Other Conductive Materials: In some cases, other metals or alloys, such as copper or palladium, may be used depending on the specific requirements of the probe card and the test application.

Dielectric Layers

Dielectric materials play a crucial role in probe cards by isolating different conductive paths to prevent signal interference and ensure accurate measurements. These materials include:

– Polyimide: A high-performance polymer with excellent electrical insulation properties and thermal stability, often used in the dielectric layers of probe cards.

– Silicon Dioxide: Commonly used in semiconductor technology, silicon dioxide provides a reliable insulating layer to separate conductive traces and minimize cross-talk between different signal paths.

– Barium Titanate: This material is used in some high-performance applications due to its high dielectric constant, which helps to improve the electrical performance of the probe card.

These materials collectively contribute to the probe card’s ability to deliver precise and reliable testing results, ensuring that semiconductor devices meet the required performance standards.

Purpose of a Probe Card

Testing Functionality

Probe cards play a critical role in testing the functionality of semiconductor devices by establishing electrical contact with the device’s pins or pads. During testing, the probe card aligns its probe pins with the contact points of the device under test (DUT). Electrical signals are then transmitted through the probes to the DUT, allowing for the evaluation of various operational parameters such as voltage, current, and signal integrity. This process helps in verifying that the semiconductor device performs as expected and meets design specifications. By enabling precise electrical connections, probe cards facilitate thorough testing of the device’s functionality, ensuring that each component operates correctly before it proceeds to further stages in the manufacturing process.

Quality Assurance

In addition to functionality testing, probe cards are essential for quality assurance in semiconductor manufacturing. They help detect defects or inconsistencies that may arise during the production of semiconductor devices. The probe card’s ability to make reliable and consistent electrical contacts is crucial for identifying issues such as shorts, opens, and incorrect signal levels. By providing detailed feedback on the device’s performance, probe cards assist in ensuring that only components meeting stringent quality standards are approved for final assembly and deployment. This quality assurance process helps prevent defective devices from reaching the market, thereby maintaining the reliability and reputation of the semiconductor manufacturer.

Together, the functionality testing and quality assurance roles of probe cards contribute to the overall reliability and efficiency of semiconductor manufacturing, ensuring that each device performs as intended and meets industry standards.

Difference Between Load Board and Probe Card

Load Board

Load boards, also known as test boards or interface boards, are crucial components in the semiconductor testing process. They serve as a platform that connects the device under test (DUT) to the test equipment. The primary functions of a load board include:

– Connecting the DUT to Test Equipment: Load boards facilitate the connection between the DUT and the testing apparatus by providing the necessary electrical pathways. They often include a series of connectors and routing paths that allow test signals to be transmitted from the test equipment to the DUT and vice versa.

– Providing a Stable Testing Platform: Load boards offer mechanical support and stability for the DUT during testing. This stability is essential for ensuring accurate and repeatable test results by minimizing movement or misalignment of the DUT.

– Incorporating Passive Components: Load boards may also include passive components, such as resistors, capacitors, and inductors, which can be used to simulate operational conditions or load effects during testing.

Probe Card

Probe cards are specialized tools designed to make direct electrical contact with the pins or pads of the DUT. Their primary functions include:

– Direct Electrical Contact: Unlike load boards, probe cards feature a series of probe pins or needles that align with the DUT’s contact points. This direct contact allows for precise measurement and testing of electrical signals, ensuring accurate evaluation of the DUT’s functionality.

– Testing Device Functionality: Probe cards are specifically engineered to perform electrical tests on the DUT, including checking voltage levels, signal integrity, and overall performance. They are an essential tool for verifying that the DUT operates correctly according to its specifications.

– Integration with Test Systems: Probe cards are integrated with automated test equipment (ATE) systems, enabling high-throughput and efficient testing of semiconductor devices.

Key Differences

The key differences between load boards and probe cards are centered around their design, purpose, and application:

– Design: Load boards are designed to provide a stable platform and connect the DUT to test equipment, often incorporating passive components for simulation. In contrast, probe cards are designed to establish direct electrical contact with the DUT’s pins for precise testing.

– Purpose: The primary purpose of a load board is to interface the DUT with test equipment and provide mechanical support. Probe cards, on the other hand, are focused on conducting electrical tests and verifying the functionality of the DUT.

– Application: Load boards are used in various testing scenarios to set up and stabilize the DUT. Probe cards are used specifically for the actual electrical testing phase, where detailed and accurate measurements are required.

Overall, while both load boards and probe cards are integral to the semiconductor testing process, they serve distinct roles that complement each other to ensure comprehensive evaluation and quality assurance of semiconductor devices.

Difference Between Cantilever and Vertical Probe Cards

Cantilever Probe Cards

Cantilever probe cards are characterized by their unique structure and design.

– Structure: Cantilever probe cards consist of a series of probes mounted on a single, flexible substrate. The probes extend from the substrate and make contact with the DUT in a cantilevered arrangement. This design allows for a large number of probe pins to be positioned over the DUT, often arranged in a grid pattern.

– Advantages: The main advantages of cantilever probe cards include their flexibility and cost-effectiveness. The cantilever design allows for easier alignment of the probes with the DUT, which is beneficial for applications requiring high-density probing. Additionally, they can be manufactured at a lower cost compared to some other types of probe cards.

– Typical Applications: Cantilever probe cards are commonly used in applications where high-density probing is required but where the mechanical stresses on the probes are manageable. They are often used in testing semiconductor devices with dense pin configurations or in production environments where cost and flexibility are important.

Vertical Probe Cards

Vertical probe cards are distinguished by their design and application characteristics.

– Design: Vertical probe cards feature a vertical arrangement of probes that come into contact with the DUT from above. The probes are mounted on a rigid, typically ceramic or high-performance composite substrate, and they maintain a vertical orientation throughout the testing process.

– Benefits: Vertical probe cards offer several benefits, including enhanced stability and durability. The vertical design minimizes probe wear and improves alignment accuracy, making them suitable for high-precision testing. They also provide better thermal management and signal integrity due to their rigid construction.

– Common Uses: Vertical probe cards are often used in high-frequency or high-power applications where precise alignment and robust performance are critical. They are commonly employed in advanced semiconductor testing environments, including those for high-performance ICs and RF devices.

Comparison

The differences between cantilever and vertical probe cards can be summarized as follows:

– Performance: Vertical probe cards generally offer better performance in terms of alignment accuracy and stability due to their rigid construction and vertical probe orientation. Cantilever probe cards, while flexible and cost-effective, may experience more wear and alignment issues over time.

– Application Suitability: Cantilever probe cards are well-suited for applications requiring high-density probing and where cost considerations are important. Vertical probe cards are preferable for applications demanding high precision, durability, and high-frequency testing.

– Design Considerations: The design of cantilever probe cards allows for a large number of probes to be used in a relatively compact space, which is advantageous for high-density DUTs. In contrast, the vertical design of probe cards provides improved mechanical stability and reduced wear, making them ideal for high-precision and high-performance testing.

In summary, while both cantilever and vertical probe cards play vital roles in semiconductor testing, the choice between them depends on specific testing requirements, including density, precision, and cost considerations.

FAQs about probe card substrate

Probe cards are made from various materials, including FR4, ceramics, and specialized composite materials for the substrate. The probe pins are typically made from tungsten or gold, and dielectric layers are used to isolate conductive paths.

Probe cards are used to make electrical contact with semiconductor devices to test their functionality and performance, ensuring they meet design specifications.

A load board connects the device under test (DUT) to test equipment and provides mechanical support, while a probe card directly contacts the DUT’s pins to conduct electrical tests.

Cantilever probe cards have probes that extend from a flexible substrate, suitable for high-density applications. Vertical probe cards have probes mounted on a rigid substrate, offering better stability and precision.