Versatile Applications: PCB Substrates Powering Electronics

A printed circuit board (PCB) is the basic framework of an electronic device, consisting of conductive paths on a non-conductive substrate. The importance of the substrate in PCB design is critical, affecting signal integrity, thermal management, and overall performance. This blog sets out to explore various aspects of PCB substrate materials, types and applications, emphasizing the critical role they play in electronic systems. By illuminating the complexities of materials like FR4, delving into dielectric factors, and understanding the role of copper layers, our goal is to help engineers make informed decisions when selecting the most appropriate PCB substrate for different applications.

PCB Substrate Basics

PCB Substrate Materials

Overview of Common Materials Used in PCB Substrates

In the realm of PCB substrates, various materials are employed to meet the diverse demands of electronic applications. One prevalent choice is FR4 (Flame Retardant 4), a widely-used substrate material known for its balance of cost-effectiveness and performance.

- FR4 (Flame Retardant 4)

a. Properties and Characteristics: FR4 is a composite material composed of woven fiberglass cloth impregnated with an epoxy resin. This combination results in a substrate with excellent electrical insulation properties, mechanical strength, and flame-retardant qualities. The woven fiberglass provides structural integrity, while the epoxy resin lends stability and electrical insulation.b. Advantages and Drawbacks: The advantages of FR4 include its widespread availability, cost-effectiveness, and compatibility with standard manufacturing processes. However, its drawbacks include limited heat resistance and may not be ideal for applications requiring extreme temperatures or stringent performance criteria.

- Other Substrate Materials (e.g., Rogers, Polyimide)

a. Specialized Applications and Features: Beyond FR4, specialized materials cater to specific application needs. Rogers materials, for instance, offer enhanced dielectric properties suitable for high-frequency applications. Polyimide, with its flexibility and high-temperature resistance, finds applications in flexible PCBs and environments with elevated temperature requirements.

b. Comparison with FR4: Comparing these materials with FR4 involves assessing factors such as dielectric constant, thermal stability, and cost. While FR4 remains a standard choice for general-purpose PCBs, materials like Rogers and Polyimide excel in particular niches, offering superior performance where required. The selection of substrate material depends on the specific demands of the application, emphasizing the importance of understanding the nuances of each material to optimize PCB performance.

PCB Dielectric Materials

Significance of Dielectric Materials in PCB Design

Dielectric materials play a critical role in PCB design by serving as insulators between conductive layers. These materials determine the electrical properties of the substrate, affecting signal propagation, impedance control, and overall performance. The dielectric constant (DK) of these materials is a key parameter influencing the speed at which electrical signals travel through the PCB.

Considerations for High-Speed Applications

In high-speed PCB designs, the choice of dielectric materials becomes even more crucial. As signal frequencies increase, minimizing signal loss and maintaining signal integrity become paramount. Low-loss dielectric materials with a stable and predictable DK over a broad frequency range are essential for high-speed applications. Additionally, factors like dissipation factor (DF), which indicates the loss of signal energy as heat, must be carefully considered to ensure minimal signal distortion.

Exploration of Various Dielectric Materials Suitable for Different Scenarios

- FR4 for Standard Applications: FR4, with its balanced electrical and mechanical properties, is commonly used for standard PCB applications. It provides a cost-effective solution for designs with moderate-speed requirements.

- Rogers Materials for High-Frequency Applications: For high-frequency applications, materials from the Rogers Corporation offer low-loss characteristics and stable DK values across a range of frequencies. These materials are specifically engineered to meet the demands of microwave and RF circuits, ensuring efficient signal transmission.

- Polyimide for Flexible PCBs: In scenarios requiring flexibility and resistance to high temperatures, polyimide-based dielectric materials are preferred. They are well-suited for flexible PCBs used in applications like wearable devices and aerospace where mechanical flexibility is essential.

- Isola and Nelco for Advanced PCB Designs: Isola and Nelco are examples of manufacturers offering advanced dielectric materials designed for high-speed and high-frequency applications. These materials often feature low DK and DF values, making them suitable for demanding electronic designs.

Understanding the unique properties of each dielectric material allows designers to tailor their choices to the specific requirements of the application, optimizing signal performance and reliability in diverse scenarios.

DK and DF in PCB

Explanation of DK (Dielectric Constant) and DF (Dissipation Factor)

DK, or Dielectric Constant, is a measure of a material’s ability to store electrical energy in an electric field. It quantifies the extent to which a material slows down the speed of an electric field passing through it. DF, or Dissipation Factor, indicates the efficiency with which a dielectric material converts electrical energy into heat. Together, DK and DF provide crucial insights into the electrical performance of dielectric materials in a PCB.

Impact of DK and DF on PCB Signal Integrity

The values of DK and DF profoundly influence the signal integrity of a PCB. A high DK can lead to increased signal delay, affecting the overall speed of signal propagation. This delay can cause signal distortion, impacting the rise and fall times of signals. On the other hand, a high DF results in greater energy loss as heat, potentially leading to signal attenuation and reduced performance. Maintaining low values for both DK and DF is essential for preserving signal quality and ensuring reliable communication within the PCB.

Importance in High-Frequency Applications

In high-frequency applications, such as those found in RF (Radio Frequency) and microwave circuits, the significance of DK and DF becomes even more critical. As signal frequencies increase, any delays or losses in signal propagation become more pronounced. Low DK values are crucial to minimizing signal dispersion, ensuring that signals travel at the desired speed. Additionally, low DF is vital to prevent excessive energy loss and maintain signal strength. High-frequency PCB designs demand meticulous attention to these parameters to meet the stringent requirements of modern communication systems, radar systems, and wireless devices.

Understanding and carefully managing DK and DF are fundamental to achieving optimal signal integrity, particularly in high-frequency applications where the impact of these parameters is magnified. Designers must consider these factors judiciously when selecting dielectric materials to guarantee the reliability and efficiency of the PCB in demanding electronic environments.

Copper Layer in PCB

Difference Between PCB and Package Substrate

Definition of Package Substrate

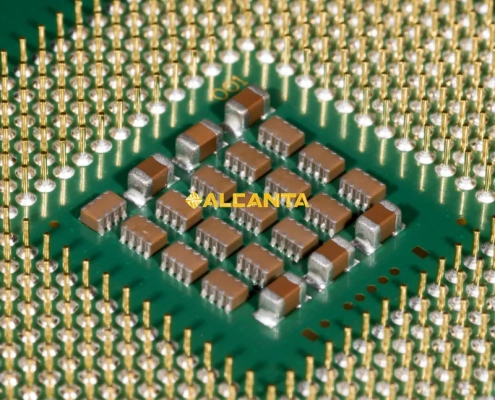

Package substrate, also known as IC (Integrated Circuit) substrate or chip substrate, is a specialized type of substrate designed to support and interconnect semiconductor devices such as microprocessors, memory chips, and other integrated circuits. Unlike traditional PCBs, package substrates are often smaller in size and tailored specifically to the requirements of the integrated circuit they house.

Contrasting Features and Applications of PCB and Package Substrate

- Size and Form Factor: PCBs are generally larger and more versatile, accommodating a wide range of electronic components. In contrast, package substrates are compact and intricately designed to fit the specific dimensions of the integrated circuit package.

- Component Integration: PCBs host a variety of components, including resistors, capacitors, and connectors. Package substrates primarily focus on providing a platform for the integration of semiconductor devices, offering precise connections for the IC’s pins.

- Complexity and Layer Structure: PCBs can have multiple layers with complex routing to support diverse circuitry. Package substrates, being tailored for specific ICs, often have simpler layer structures optimized for the electrical connections required by the integrated circuit.

- Manufacturing Processes: PCBs are typically manufactured using standard PCB fabrication processes. Package substrates, on the other hand, may involve more specialized processes such as flip-chip bonding or wire bonding, tailored to the specific requirements of the integrated circuit.

- Applications: PCBs find application in a wide range of electronic devices, from consumer electronics to industrial equipment. Package substrates are specifically designed for integrated circuits and are prevalent in devices like smartphones, computers, and other electronic gadgets.

Instances Where Each is Preferred

- PCB Preference:

- PCBs are preferred in applications requiring a broad range of components, such as in computers, telecommunications equipment, and power supplies.

- When the design demands versatility and the accommodation of various electronic elements, PCBs are the preferred choice.

- Package Substrate Preference:

- Package substrates are preferred in the semiconductor industry for mounting integrated circuits, where size and weight considerations are crucial.

- For advanced electronic devices like microprocessors and memory chips, package substrates offer tailored support and efficient interconnection.

Understanding the specific needs of the application is essential in determining whether a traditional PCB or a package substrate is the more suitable choice. The selection depends on factors such as size constraints, component integration requirements, and the nature of the electronic device being developed.

Chip Substrate

Overview of Chip Substrate in the Context of PCBs

Chip substrates, integral to the field of PCBs, serve as a specialized platform designed explicitly for the mounting and interconnection of semiconductor devices. These substrates are crucial components that bridge the gap between the intricate world of microelectronics and the broader functionality of Printed Circuit Boards.

Role in Supporting and Connecting Semiconductor Devices

The primary role of chip substrates is to provide a stable foundation for the placement and interconnection of semiconductor devices, such as integrated circuits (ICs), microprocessors, and memory chips. These substrates offer a compact and precise environment where the delicate silicon-based components can be securely affixed and connected. The intricate network of conductive pathways on chip substrates ensures efficient communication between the semiconductor devices, contributing to the seamless operation of the electronic system.

Compatibility with Different PCB Substrate Materials

Chip substrates exhibit a degree of compatibility with various PCB substrate materials, but the selection often depends on the specific requirements of the semiconductor device and the overall electronic system. Key considerations include:

- Thermal Compatibility

- The thermal properties of chip substrates must align with those of the chosen PCB substrate material. This ensures efficient heat dissipation from the semiconductor devices to maintain optimal operating temperatures.

- Dielectric Matching

- Matching the dielectric properties of the chip substrate with the PCB substrate is crucial for maintaining signal integrity and preventing impedance mismatches in high-frequency applications.

- Material Consistency

- Consistency in material properties between the chip substrate and the PCB substrate contributes to the overall reliability of the electronic system. This consistency helps avoid issues such as differential expansion or contraction during temperature variations.

- Manufacturing Processes

- The manufacturing processes for chip substrates should align with those used in PCB fabrication to ensure compatibility and seamless integration into the overall assembly.

- Specialized Requirements

- In certain cases, where specific electronic applications demand unique characteristics, chip substrates may be customized to meet the requirements of the semiconductor devices and the overall system.

Understanding the compatibility between chip substrates and PCB substrate materials is essential for achieving a harmonious integration of semiconductor devices within electronic systems. This consideration ensures optimal performance, reliability, and longevity of the interconnected components.

PCB Substrate Types

What is the difference between PCB and package substrate?

A Printed Circuit Board (PCB) is a flat board that mechanically supports and electrically connects electronic components through conductive pathways. It accommodates a variety of components and is integral to the construction of electronic devices. On the other hand, a package substrate is a specialized substrate designed specifically to support and interconnect semiconductor devices, such as microprocessors and memory chips. While PCBs are more versatile and can host a broad range of components, package substrates are tailored to the specific needs of integrated circuits.

What is FR4 substrate for PCB?

FR4, or Flame Retardant 4, is a common substrate material used in the construction of PCBs. It is a composite material consisting of woven fiberglass cloth impregnated with an epoxy resin. FR4 is known for its electrical insulation properties, mechanical strength, and flame-retardant characteristics. It is widely utilized in general-purpose electronic applications where a balance of performance and cost-effectiveness is required.

What is PCB base material?

The PCB base material, also referred to as the substrate or core material, is the foundation of the PCB. It provides a sturdy platform for the arrangement and interconnection of electronic components. The base material is typically made of fiberglass-reinforced epoxy laminate, with FR4 being a commonly used variant. The base material contributes to the PCB’s mechanical strength, dielectric properties, and overall reliability.

What is substrate like PCB manufacturing?

In the context of PCB manufacturing, the term “substrate” refers to the base material onto which the conductive pathways and electronic components are assembled. The substrate provides structural support, electrical insulation, and a surface for the placement of components. During the manufacturing process, layers of conductive copper traces are etched onto the substrate, forming the intricate circuitry. Substrate materials like FR4 are chosen based on the specific requirements of the application, ensuring optimal performance and reliability in electronic systems.