Key Benefits of Lead Frames Material C-194 F.H. in Electronics

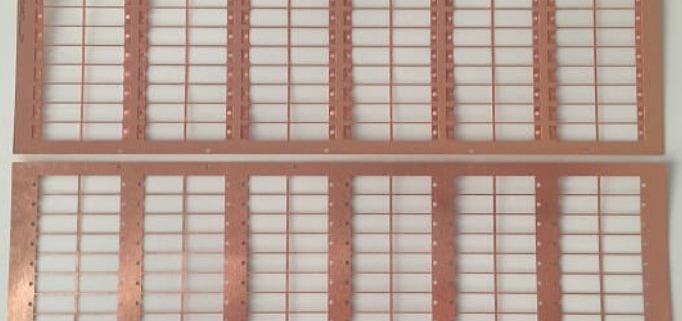

Lead frames are essential components in semiconductor device assembly, providing the metal base that supports and electrically connects the integrated circuit (IC) to the external circuitry. They act as a bridge between the chip and the package, ensuring proper electrical paths for signals and heat dissipation. The role of lead frames in electronic devices is crucial, as they enable effective power delivery and data transmission, allowing the IC to function within the system. In packaging technology, Lead Frames Material C-194 F.H. plays a central role due to its superior electrical and thermal properties, which meet the high demands of modern electronic applications. C-194 F.H. material ensures lead frames provide durability, efficiency, and reliability in high-performance environments.

What is Lead Frames Material C-194 F.H.?

Lead Frames Material C-194 F.H. is a high-performance copper alloy widely used in the production of lead frames for semiconductor packaging. Known for its excellent electrical and thermal conductivity, C-194 F.H. is a copper-based material with enhanced properties, making it an ideal choice for applications in the electronics industry, especially in devices requiring reliable performance under demanding conditions.

Chemical Composition and Characteristics of Lead Frames Material C-194 F.H.

C-194 F.H. is primarily composed of copper (Cu), with a small percentage of other elements like tin (Sn), phosphorous (P), and silver (Ag). The alloy typically contains around 95-98% copper, with the remaining elements providing specific enhancements to its mechanical properties. Tin and phosphorous contribute to the alloy’s strength and resistance to corrosion, while silver improves its electrical conductivity, making the material more effective for high-performance applications.

Why Lead Frames Material C-194 F.H. is Commonly Used in Lead Frames

C-194 F.H. is a popular choice for lead frames due to its unique balance of strength, electrical conductivity, and corrosion resistance. These qualities are critical for ensuring long-term performance in semiconductor devices, where even minor failures can lead to significant issues. The material is particularly favored for its stability in high-temperature environments, making it an ideal candidate for use in modern electronic systems that generate substantial heat during operation.

Unique Physical and Electrical Properties of Lead Frames Material C-194 F.H.

One of the standout features of Lead Frames Material C-194 F.H. is its superior electrical conductivity, which is essential for minimizing power loss and ensuring efficient signal transmission between the chip and the external circuitry. Additionally, the material offers excellent thermal conductivity, aiding in heat dissipation and preventing overheating in semiconductor packages.

C-194 F.H. also boasts high strength and durability, making it resistant to mechanical stress and fatigue over time. This combination of electrical and mechanical properties ensures that lead frames made from C-194 F.H. maintain reliability throughout the lifetime of the electronic device, even in demanding conditions. These characteristics make C-194 F.H. a top choice for industries where high performance and longevity are crucial, such as automotive electronics, consumer devices, and industrial applications.

Basic Components and Design of Lead Frames Using Lead Frames Material C-194 F.H.

Lead frames are an essential part of semiconductor packaging, and their design and structure are crucial for ensuring the proper function and longevity of the integrated circuit (IC). Lead Frames Material C-194 F.H. plays a vital role in this design, providing the necessary strength, electrical conductivity, and durability to ensure high-performance packaging.

Core Components of a Lead Frame

A typical lead frame consists of several key components that work together to support and connect the semiconductor device. These include:

-

Frame: The frame forms the base structure of the lead frame, providing mechanical stability. It holds the die (the semiconductor chip) in place and also supports the leads that connect to the external circuits. The frame is typically made of copper or copper alloys like Lead Frames Material C-194 F.H. due to its superior strength and ability to withstand mechanical stress.

-

Leads: The leads extend from the frame and are the points through which electrical connections are made to the external circuits. They are usually thin metal fingers that must be carefully designed for optimal signal flow. In lead frames made from C-194 F.H., these leads benefit from the material’s excellent electrical conductivity and strength, ensuring reliable performance.

-

Die Pad: This is the flat surface within the lead frame where the semiconductor die is mounted. The die pad ensures proper alignment and thermal dissipation for the chip. C-194 F.H. material contributes to the heat transfer properties of the die pad, helping to regulate temperature within the device.

-

Tie Bars: These are structural elements that connect the leads to the frame, providing additional mechanical support. They also allow for easy handling and positioning of the lead frame during the manufacturing process. In C-194 F.H. lead frames, tie bars provide high strength while maintaining flexibility during production.

Design of a Lead Frame: Frame, Leads, and Other Elements

The design of a lead frame is critical for ensuring that the semiconductor package can be efficiently manufactured and function reliably in its final application. In general, the design focuses on balancing electrical and mechanical properties, such as:

-

Frame Size and Shape: The frame’s dimensions are designed to accommodate the specific semiconductor die size, ensuring it holds the chip securely while providing adequate space for the leads to make connections.

-

Lead Configuration: The number and placement of leads are tailored to match the required number of connections for the IC. Lead frames can have different lead types, such as gull-wing or J-leads, depending on the packaging needs. The electrical performance of the leads, including their ability to carry current with minimal resistance, is significantly enhanced when using Lead Frames Material C-194 F.H..

-

Thermal Management: The design must also consider heat dissipation, as semiconductor devices generate heat during operation. Copper alloys like C-194 F.H. have excellent thermal conductivity, allowing the lead frame to help manage heat and ensure that the device performs efficiently without overheating.

Specific Application of Lead Frames Material C-194 F.H. in Lead Frame Designs

Lead Frames Material C-194 F.H. is particularly well-suited for lead frame designs due to its combination of high strength, good conductivity, and resistance to corrosion. It is often used in applications where both electrical and mechanical reliability are paramount, such as in automotive electronics, LED packaging, and high-frequency communication devices.

In semiconductor packages that need to operate in harsh environments, C-194 F.H. ensures that the lead frame can handle high currents without degradation, and it also improves the overall longevity of the package. The material’s resistance to mechanical stress ensures that lead frames maintain their structural integrity over time, even in compact designs with high lead count. This makes Lead Frames Material C-194 F.H. the material of choice for high-performance, high-reliability applications.

By leveraging the strengths of C-194 F.H. in the design of lead frames, manufacturers can produce semiconductor packages that meet the stringent requirements of modern electronics.

Common Materials Used in Lead Frames: A Comparison with Lead Frames Material C-194 F.H.

Lead frames are predominantly made from copper-based materials, which are chosen for their excellent electrical conductivity, thermal properties, and mechanical strength. Lead Frames Material C-194 F.H. is one of the most popular alloys used for this purpose due to its superior performance. However, there are other copper alloys and pure copper options available that offer distinct advantages and trade-offs depending on the application requirements.

Copper-Based Materials: Copper Alloys and Pure Copper

Copper and copper alloys are the primary materials used in the manufacturing of lead frames due to their outstanding electrical and thermal conductivity, which are essential for the reliable performance of semiconductor devices. The two main categories of copper materials used in lead frames are:

-

Pure Copper (C-10100): This is a high-purity copper (typically 99.99%) that offers the best electrical conductivity of any material. It is often used in applications where optimal conductivity is paramount, such as in power electronics or high-frequency circuits. However, while pure copper has excellent conductivity, it lacks the strength and durability needed for many lead frame applications, which is why it is often alloyed with other metals.

-

Copper Alloys: Copper alloys, such as C-194 F.H., C-7025, and others, are designed to improve upon the properties of pure copper. These alloys are engineered to offer a balance between conductivity and mechanical strength. The addition of elements such as tin, phosphorous, and silver enhances certain characteristics, making these materials more suitable for lead frames that need to withstand mechanical stress and high temperatures.

Pros and Cons of Various Copper Alloys

Different copper alloys offer distinct advantages and disadvantages when used in lead frames. Let’s take a closer look at some of the key copper alloys used in semiconductor packaging:

-

C-194 F.H.:

- Pros:

- High Strength: One of the key benefits of Lead Frames Material C-194 F.H. is its excellent mechanical strength. This ensures that the lead frame can withstand stress and maintain structural integrity over time.

- Excellent Electrical and Thermal Conductivity: C-194 F.H. provides good electrical conductivity, ensuring efficient signal transfer between the semiconductor and external circuitry. It also offers good thermal conductivity, which helps in heat dissipation.

- Corrosion Resistance: The alloy is highly resistant to corrosion, making it ideal for use in harsh environments, such as automotive or outdoor electronics.

- Cons:

- Cost: C-194 F.H. can be more expensive than pure copper or other alloys due to its superior properties and manufacturing process.

- Workability: While it is more durable than pure copper, C-194 F.H. can be slightly more challenging to process due to its strength and hardness.

- Pros:

-

C-7025 (Copper-Nickel Alloy):

- Pros:

- High Strength: C-7025 is a copper-nickel alloy that offers excellent strength and wear resistance, making it suitable for demanding applications.

- Corrosion Resistance: The nickel content provides better resistance to corrosion compared to pure copper, particularly in marine or harsh industrial environments.

- Cons:

- Lower Electrical Conductivity: While C-7025 is stronger than pure copper, it has lower electrical conductivity, which might not be suitable for high-performance semiconductor devices that require optimal signal transmission.

- More Expensive: The addition of nickel raises the cost compared to pure copper alloys, making it less economical for some applications.

- Pros:

-

C-10100 (Pure Copper):

- Pros:

- Best Electrical Conductivity: Pure copper offers the highest electrical conductivity, which is crucial for certain high-performance applications like power electronics and high-frequency circuits.

- Ease of Processing: Pure copper is relatively easy to form and process, making it ideal for applications where complex lead frame shapes are required.

- Cons:

- Lower Strength: The main drawback of pure copper is its relatively low strength compared to copper alloys. This makes it less suitable for applications where mechanical robustness is critical, such as lead frames exposed to mechanical stresses.

- Prone to Corrosion: Pure copper is more susceptible to oxidation and corrosion, especially in harsh environmental conditions, limiting its long-term durability.

- Pros:

Comparison of C-194 F.H. with Other Common Materials (e.g., C-10100, C-7025)

When comparing Lead Frames Material C-194 F.H. with other common materials like C-10100 (pure copper) and C-7025 (copper-nickel alloy), several key differences stand out:

-

Electrical Conductivity: While pure copper (C-10100) offers the highest electrical conductivity, Lead Frames Material C-194 F.H. provides a balanced performance with good conductivity, suitable for most lead frame applications. However, C-194 F.H. sacrifices a bit of electrical performance in exchange for superior strength and mechanical properties.

-

Mechanical Strength: C-194 F.H. excels in terms of strength and durability, making it ideal for lead frames that must withstand mechanical stress, such as those in automotive or industrial applications. C-7025 also offers high strength but at the cost of lower electrical conductivity. On the other hand, C-10100 (pure copper) is weaker and more prone to physical damage, making it less suitable for high-stress environments.

-

Corrosion Resistance: Both C-194 F.H. and C-7025 exhibit excellent corrosion resistance, with C-7025 being particularly strong in marine or industrial environments due to the presence of nickel. C-10100, while offering exceptional electrical properties, is more susceptible to corrosion and may require additional coatings or treatments in more demanding environments.

-

Cost: C-194 F.H. is typically more expensive than pure copper due to the alloying elements used to enhance its strength and durability. However, its superior performance in high-stress and high-temperature environments justifies the additional cost. C-7025 is also more expensive due to the inclusion of nickel, while C-10100 is the most cost-effective option, though it may not provide the same level of mechanical reliability.

Lead Frames Material C-194 F.H. strikes a balance between high strength, good electrical conductivity, and excellent corrosion resistance, making it a top choice for applications where reliability and durability are crucial. While pure copper and copper-nickel alloys have their respective advantages, C-194 F.H. stands out as a versatile material suitable for a wide range of semiconductor packaging applications.

Advantages of Lead Frames Material C-194 F.H.

Lead Frames Material C-194 F.H. offers a range of distinct advantages, making it the material of choice for high-performance lead frames used in semiconductor packaging. These advantages stem from its unique combination of physical, electrical, and thermal properties, which ensure both reliability and efficiency in demanding applications.

High Strength and Excellent Ductility

One of the key benefits of Lead Frames Material C-194 F.H. is its high strength combined with excellent ductility. The material is engineered to withstand significant mechanical stress without compromising its structural integrity. This is particularly important in applications where lead frames need to endure physical manipulation during the manufacturing process or face mechanical stress once deployed in the final electronic device.

Despite its high strength, C-194 F.H. remains highly ductile, which means it can be easily formed into the required shapes without cracking or breaking. This property is critical during the stamping or molding process, where precise shaping is needed for the lead frame to fit perfectly within the package. This combination of strength and ductility ensures that lead frames made from C-194 F.H. maintain both durability and flexibility, making them ideal for complex packaging designs that demand reliability under stress.

Superior Electrical and Thermal Conductivity

Another significant advantage of Lead Frames Material C-194 F.H. is its superior electrical and thermal conductivity. Copper alloys like C-194 F.H. are renowned for their ability to efficiently conduct electricity, which is essential for semiconductor devices that need to transmit electrical signals between the chip and external circuits.

The electrical conductivity of C-194 F.H. ensures that power delivery and signal transmission occur with minimal resistance, which reduces power loss and heat generation. This is particularly important in applications such as power electronics, where high current levels need to be handled efficiently.

In addition to electrical conductivity, C-194 F.H. also boasts excellent thermal conductivity. Heat dissipation is a critical factor in maintaining the longevity and performance of semiconductor devices. The thermal properties of C-194 F.H. allow it to effectively transfer heat away from the chip, reducing the risk of overheating and ensuring that the device operates within its optimal temperature range. This is especially important in high-performance applications such as automotive electronics, LED packaging, and communication devices, where efficient heat management is crucial for preventing component failure.

Corrosion Resistance and Long-Term Reliability

Corrosion resistance is another key feature that sets Lead Frames Material C-194 F.H. apart from other materials. In many environments, lead frames are exposed to humidity, chemicals, and other corrosive elements that can cause degradation over time. C-194 F.H. is highly resistant to such corrosion, thanks to the alloying elements like tin and phosphorous, which enhance the material’s durability in challenging conditions.

This resistance to corrosion translates to long-term reliability in a variety of applications. Whether used in automotive, industrial, or consumer electronics, lead frames made from C-194 F.H. are less likely to fail due to material degradation over time. This ensures that the semiconductor packages remain operational for the full life cycle of the device, reducing the need for maintenance or replacement and improving the overall reliability of the electronic product.

Suitability for High-Temperature Environments and Complex Packaging Requirements

Lead Frames Material C-194 F.H. is particularly well-suited for high-temperature environments and complex packaging requirements. Many modern semiconductor devices operate under conditions where they are subjected to elevated temperatures, either due to their internal circuitry or the operating environment. C-194 F.H. is designed to perform reliably even under such conditions, thanks to its high melting point and excellent thermal stability.

The material’s ability to retain its mechanical and electrical properties at high temperatures makes it ideal for use in automotive electronics, power devices, and other applications where devices must withstand temperature fluctuations or extreme heat. Additionally, C-194 F.H. is well-suited for complex packaging needs, such as those found in multi-chip modules or other advanced semiconductor packaging formats. Its combination of strength, thermal conductivity, and corrosion resistance allows it to meet the demands of intricate, high-density packaging without compromising performance.

Lead Frames Material C-194 F.H. offers several distinct advantages that make it the material of choice for high-performance lead frames in semiconductor packaging. Its high strength and ductility, superior electrical and thermal conductivity, corrosion resistance, long-term reliability, and suitability for high-temperature and complex packaging requirements ensure that devices using C-194 F.H. remain robust, efficient, and durable throughout their operational life. These qualities make it an ideal choice for industries demanding the highest standards of performance and reliability, such as automotive, telecommunications, and consumer electronics.

Lead Frame Plating: What is Lead Frame Plating with Lead Frames Material C-194 F.H.?

Lead Frames Material C-194 F.H. is widely used in semiconductor packaging due to its excellent mechanical, electrical, and thermal properties. However, to further enhance its performance and ensure reliability in real-world applications, lead frame plating is an essential step in the manufacturing process. Lead frame plating refers to the process of coating the surface of the lead frame with a thin layer of metal to improve its performance, longevity, and reliability in various environments.

The Necessity of Surface Treatments

Surface treatments, such as plating, are critical for lead frames, as they provide multiple benefits that raw materials, like Lead Frames Material C-194 F.H., may not offer on their own. One of the primary reasons for plating is to improve corrosion resistance. Lead frames are exposed to harsh environments, including moisture, heat, and chemicals, which can cause degradation over time. Plating provides a protective layer that prevents oxidation and corrosion, extending the life of the component and maintaining the integrity of electrical connections.

In addition to corrosion resistance, plating can improve electrical conductivity. For example, some plating materials can reduce the contact resistance between the lead frame and the semiconductor, ensuring that signals and power are transmitted efficiently. Surface treatments also improve solderability, making it easier for the lead frame to connect with external circuits during the assembly process.

Plating can enhance the mechanical properties of the lead frame, improving its wear resistance and reducing the likelihood of mechanical failure due to stress, vibration, or handling. This is particularly important for devices that operate in demanding environments or require a long operational lifespan.

Common Plating Methods: Gold, Silver, Nickel, etc.

There are several plating methods commonly used in the semiconductor industry, each offering distinct advantages based on the specific needs of the application. Some of the most widely used plating methods include:

-

Gold Plating:

Gold plating is one of the most commonly used plating methods in lead frame manufacturing. It provides excellent corrosion resistance and electrical conductivity, making it ideal for high-frequency and high-reliability applications. Gold plating is often used in applications like high-end consumer electronics, automotive electronics, and military-grade devices, where performance and longevity are critical. Gold-plated lead frames provide long-term protection against oxidation, ensuring stable electrical connections.- Advantages: High corrosion resistance, excellent conductivity, and long-term reliability.

- Disadvantages: Expensive, making it unsuitable for cost-sensitive applications.

-

Silver Plating:

Silver plating is another popular choice, particularly when cost-effectiveness is important. Silver offers superior electrical conductivity, which makes it ideal for applications requiring high signal fidelity and low resistance. However, silver is more prone to tarnishing over time, which can affect its performance in certain environments. Silver plating is often used in applications where performance outweighs long-term exposure to environmental conditions.- Advantages: Excellent electrical conductivity at a lower cost than gold.

- Disadvantages: Susceptible to tarnishing and corrosion, especially in humid or high-temperature environments.

-

Nickel Plating:

Nickel plating is commonly used for corrosion resistance and mechanical strength. It is often applied as a base layer under other precious metal coatings, such as gold or silver. Nickel is highly resistant to oxidation and can provide a protective barrier for the underlying lead frame. Nickel plating is frequently used in more cost-sensitive applications where the ultimate performance is not as critical, or as an undercoat for more expensive metals like gold or silver.- Advantages: Excellent corrosion resistance, wear resistance, and mechanical strength.

- Disadvantages: Lower electrical conductivity compared to gold and silver.

-

Tin Plating:

Tin plating is typically used in applications where solderability is the most important factor. Tin-plated lead frames offer good solderability and are often found in consumer electronics and other mass-market products. While tin plating offers great performance in terms of connecting to external circuits, it is not as effective as other coatings in terms of corrosion resistance and long-term durability.- Advantages: Excellent solderability and low cost.

- Disadvantages: Poor corrosion resistance and lower conductivity compared to gold or silver.

Performance of C-194 F.H. Material Under Different Plating Methods

The performance of Lead Frames Material C-194 F.H. can vary significantly depending on the plating method used. Here’s how it performs under different surface treatments:

-

Gold Plating:

When Lead Frames Material C-194 F.H. is gold-plated, the result is a highly reliable lead frame with excellent electrical conductivity and outstanding corrosion resistance. The high strength and ductility of C-194 F.H. are complemented by the gold layer, which ensures long-lasting, stable electrical connections. This makes gold-plated C-194 F.H. ideal for high-end applications like automotive electronics and medical devices, where both performance and durability are crucial. -

Silver Plating:

Lead Frames Material C-194 F.H. plated with silver provides excellent electrical conductivity, making it a suitable choice for applications that require low contact resistance. However, silver’s tendency to tarnish in humid or high-temperature environments can reduce the material’s overall performance over time. While the C-194 F.H. alloy’s inherent corrosion resistance helps mitigate some of these issues, silver-plated lead frames may not be the best choice for long-term reliability in harsh environments. -

Nickel Plating:

Nickel plating on Lead Frames Material C-194 F.H. offers great corrosion resistance and mechanical strength, especially in industrial and outdoor environments. The nickel layer adds durability and wear resistance, ensuring that the lead frame can withstand physical stresses. However, the electrical conductivity of nickel is lower than that of gold or silver, which might be a concern in applications where signal fidelity and efficiency are paramount. -

Tin Plating:

Lead Frames Material C-194 F.H. with tin plating is commonly used for applications that require excellent solderability. The tin layer ensures that the lead frame can form reliable connections with external circuits during the assembly process. However, while tin plating provides good solderability, it offers lower corrosion resistance and lower electrical conductivity compared to gold or silver coatings. For high-performance or high-reliability applications, tin-plated lead frames may not be as suitable.

Lead Frames Material C-194 F.H. is an excellent base material for lead frame manufacturing, and when combined with the right plating, it can provide enhanced durability, electrical performance, and corrosion resistance. Gold, silver, nickel, and tin plating methods each offer unique advantages, depending on the specific application and performance requirements. Gold and silver plating provide the best electrical conductivity and corrosion resistance, while nickel plating enhances mechanical properties and wear resistance. Tin plating, though cost-effective, is typically used when solderability is the primary concern. The appropriate choice of plating for Lead Frames Material C-194 F.H. will depend on the balance between performance needs and cost considerations for the final electronic device.

Applications of Lead Frames Material C-194 F.H.

Lead Frames Material C-194 F.H. has become a preferred choice in a wide range of industries due to its unique combination of high strength, excellent electrical and thermal conductivity, and corrosion resistance. Its versatile properties make it suitable for use in various packaging applications, especially those that demand durability, performance, and reliability. Below, we explore the key applications of C-194 F.H. material in lead frames, focusing on automotive electronics, consumer electronics, LED packaging, and more.

Use in Automotive Electronics, Consumer Electronics, LED Packaging, and More

-

Automotive Electronics:

The automotive industry demands components that can withstand extreme temperatures, vibration, and corrosion. Lead Frames Material C-194 F.H. is particularly well-suited for automotive electronics due to its high mechanical strength, corrosion resistance, and ability to maintain reliable electrical connections in challenging environments. These properties are essential for electronic systems used in engines, sensors, infotainment, and safety systems, where long-term durability and stable performance are critical. C-194 F.H. ensures that lead frames remain robust and functional, even under high heat and pressure, making them an excellent choice for applications like engine control units (ECUs) and advanced driver assistance systems (ADAS). -

Consumer Electronics:

Lead Frames Material C-194 F.H. is widely used in consumer electronics, where reliable electrical conductivity and thermal management are essential. This material is commonly found in smartphones, tablets, laptops, and wearable devices. The combination of high electrical conductivity and mechanical strength in C-194 F.H. ensures the efficient transfer of signals and power within these compact devices. As consumer electronics continue to evolve towards smaller, more powerful devices, C-194 F.H. material provides the required performance for miniaturized packaging, ensuring that devices remain reliable even in small, thermally demanding environments. -

LED Packaging:

In the LED industry, the demand for efficient heat dissipation and long-lasting performance is high. Lead Frames Material C-194 F.H. plays a critical role in LED packaging, where it helps in the efficient transfer of heat away from the LED chip. The thermal conductivity of C-194 F.H. ensures that the heat generated by the LED is dissipated effectively, preventing overheating and ensuring the longevity of the LED. The material’s corrosion resistance is also crucial in LED applications, where lead frames are exposed to various environmental conditions. As LED technology continues to evolve, C-194 F.H. remains a top choice for high-power LED packages used in automotive lighting, street lights, and commercial lighting. -

Industrial and Communication Devices:

Lead Frames Material C-194 F.H. is also used in industrial electronics and communication devices, such as servers, networking equipment, and power supplies. In these applications, the material’s high strength and thermal stability are essential for handling the heat generated by high-performance components. Furthermore, its electrical conductivity ensures minimal signal loss, which is important in maintaining performance for high-frequency devices. Whether in industrial control systems or communication infrastructure, C-194 F.H. offers the reliability needed for continuous operation under demanding conditions.

Different Packaging Types and Their Specific Requirements for C-194 F.H.

The requirements for lead frames vary depending on the type of packaging used in semiconductor devices. Different packaging types, such as dual in-line packages (DIP), ball grid arrays (BGA), and chip-on-board (COB) packages, have distinct design needs that Lead Frames Material C-194 F.H. can address. Here are some common packaging types and how C-194 F.H. meets their specific requirements:

-

Dual In-Line Packages (DIP):

DIPs are one of the most traditional types of semiconductor packaging. They require lead frames that can handle the mechanical stress of inserting the component into a circuit board, while also ensuring stable electrical connections. Lead Frames Material C-194 F.H. offers the necessary strength and ductility to be stamped into the precise shapes required for DIP configurations, providing reliable long-term performance. The corrosion resistance of C-194 F.H. ensures that the DIP lead frame remains reliable in environments exposed to moisture or temperature fluctuations. -

Ball Grid Arrays (BGA):

BGA packaging involves a grid of solder balls at the base of the package, allowing for high-density interconnects. This type of packaging demands lead frames that can handle high temperatures and provide excellent electrical conductivity. Lead Frames Material C-194 F.H. meets these requirements with its high thermal conductivity and mechanical strength, ensuring that the semiconductor package performs reliably under high temperatures and during the soldering process. The corrosion resistance also helps maintain the integrity of the BGA package over its lifecycle. -

Chip-on-Board (COB) Packaging:

In COB packaging, the semiconductor die is directly mounted onto the lead frame and encapsulated in resin. This packaging type requires lead frames with excellent heat dissipation properties to prevent damage to the die. Lead Frames Material C-194 F.H. is a great choice for COB packaging due to its thermal conductivity and corrosion resistance, which helps keep the chip cool and protected over time. The material’s strength ensures that the lead frame can handle the stresses of handling and packaging without compromising the device’s performance. -

Plastic Leaded Chip Carrier (PLCC):

PLCC packages also use lead frames for the interconnection of the chip and the external circuit. These packages require lead frames that offer strength and corrosion resistance for long-term stability, particularly in consumer and industrial applications. Lead Frames Material C-194 F.H. provides the necessary properties to ensure reliable performance in PLCC packages, ensuring the device functions properly in a range of applications from home appliances to industrial machinery.

Real-World Case Studies: Applications of C-194 F.H. Material in Various Industries

-

Automotive Industry:

In automotive electronics, Lead Frames Material C-194 F.H. is used in the packaging of components like powertrain control units, infotainment systems, and sensor modules. For example, an automotive manufacturer used C-194 F.H. in the ECUs for electric vehicles (EVs), where the lead frames needed to endure both high temperatures and frequent vibrations. The combination of high strength and thermal conductivity of C-194 F.H. allowed the lead frames to maintain their structural integrity and electrical reliability over time, even in the demanding automotive environment. -

Consumer Electronics:

A leading smartphone manufacturer used Lead Frames Material C-194 F.H. in the packaging of its high-performance microprocessors and memory chips. These devices required lead frames with high electrical conductivity for optimal signal transfer and corrosion resistance to ensure long-term durability in consumer electronics. C-194 F.H. provided the perfect solution, enabling efficient packaging while maintaining the performance of these critical components. -

LED Lighting:

In the LED lighting industry, C-194 F.H. has been used in high-power LED packages for automotive lighting and street lights. A manufacturer of automotive headlights used C-194 F.H. in the lead frames for their high-intensity LED chips, ensuring efficient heat dissipation and protection against environmental factors such as humidity and temperature variations. The material’s corrosion resistance and thermal conductivity made it the ideal choice for this demanding application.

Lead Frames Material C-194 F.H. has proven its versatility and reliability across various industries, including automotive electronics, consumer electronics, LED packaging, and more. Its unique combination of high strength, electrical conductivity, corrosion resistance, and thermal stability makes it an ideal material for semiconductor packaging in both standard and advanced packaging types. From DIP to BGA and COB, C-194 F.H. continues to meet the growing demands of the industry, ensuring long-term reliability and high performance in a wide range of applications.

Factors to Consider When Choosing Lead Frames Material C-194 F.H.

Choosing the right material for lead frames is a crucial decision in semiconductor packaging, as it directly impacts both the cost and performance of the final product. Lead Frames Material C-194 F.H. has become a popular choice in various industries due to its unique combination of properties, but there are several factors to consider when determining if this material is the best option for a specific application. Below, we explore the impact of material choice on cost and performance, current market trends of C-194 F.H., and how to assess its suitability for different applications.

Impact of Material Choice on Cost and Performance

-

Cost Considerations:

The material selected for lead frames can significantly influence the production cost of semiconductor devices. While Lead Frames Material C-194 F.H. offers exceptional performance in terms of strength, conductivity, and corrosion resistance, it is generally more expensive than other materials such as pure copper or brass. The higher cost of C-194 F.H. is typically justified by its superior properties, especially in high-performance applications where reliability and durability are critical. However, manufacturers must carefully assess whether the added cost of C-194 F.H. aligns with the overall product requirements, especially when considering mass production or cost-sensitive markets. -

Performance Benefits:

The performance of Lead Frames Material C-194 F.H. is its primary selling point. The material’s excellent electrical conductivity, high thermal conductivity, corrosion resistance, and mechanical strength ensure that components made with this material perform reliably in high-temperature and high-stress environments. These attributes make it ideal for industries such as automotive electronics, LED lighting, and high-performance consumer electronics. The thermal stability of C-194 F.H. also ensures that devices remain operational even under continuous use in demanding conditions, which is often essential for mission-critical applications. -

Balancing Cost and Performance:

When choosing Lead Frames Material C-194 F.H., manufacturers must weigh the performance benefits against the cost to determine whether the material offers the right value for their specific application. For example, in high-end applications like automotive or LED lighting, where long-term reliability and high performance are essential, the investment in C-194 F.H. material is often well worth the cost. On the other hand, for low-cost consumer electronics, a different material might be chosen to balance cost-efficiency and acceptable performance.

Market Trends of C-194 F.H. Material

-

Growing Demand in Advanced Electronics:

As electronic devices become more compact, powerful, and thermally demanding, there is a growing need for lead frames that can withstand higher temperatures, mechanical stress, and electrical loads. Lead Frames Material C-194 F.H. is well-positioned to meet these demands, especially in applications such as automotive electronics, LED packaging, and high-performance consumer electronics. As the electronics industry continues to push the boundaries of performance and miniaturization, the demand for advanced materials like C-194 F.H. is expected to rise. -

Shift Towards Eco-friendly and Sustainable Materials:

Another significant trend in the market is the increasing focus on eco-friendly and sustainable materials in electronics manufacturing. While Lead Frames Material C-194 F.H. itself is not inherently harmful to the environment, its corrosion resistance and durability contribute to longer-lasting components, which can help reduce waste and improve sustainability over time. As the industry continues to move towards green manufacturing practices, C-194 F.H. is well-positioned as a material that not only performs well but also contributes to the overall lifecycle of products. -

Integration of Advanced Materials in Packaging:

The trend of integrating advanced materials in packaging technology is pushing the demand for lead frames that offer exceptional electrical and thermal properties. In this context, Lead Frames Material C-194 F.H. is often preferred over other materials because it offers the thermal stability and corrosion resistance needed to ensure that high-performance packages remain operational over time. This makes C-194 F.H. an ideal choice for next-generation packaging solutions in industries such as automotive and telecommunications, where the performance demands of devices are increasing.

How to Assess the Suitability of C-194 F.H. for Specific Applications

-

Environmental and Thermal Conditions:

One of the first factors to consider when assessing the suitability of Lead Frames Material C-194 F.H. is the operating environment of the device. If the application involves high temperatures, frequent vibrations, or exposure to moisture or corrosive substances, C-194 F.H. is an excellent choice due to its thermal conductivity and corrosion resistance. For example, in automotive electronics, where components are exposed to extreme temperature fluctuations and harsh environmental conditions, the thermal stability and mechanical strength of C-194 F.H. are essential. -

Electrical and Mechanical Performance Requirements:

The electrical conductivity and mechanical strength of Lead Frames Material C-194 F.H. make it a top choice for applications where reliable signal transfer and robust packaging are critical. In applications such as LED lighting and high-frequency communication systems, the need for efficient thermal management and electrical performance makes C-194 F.H. an ideal material for lead frames. Evaluating the current and signal integrity requirements of the specific application can help determine if C-194 F.H. is suitable. -

Long-Term Reliability and Durability:

Long-term reliability is a key consideration in many industries, particularly those involving mission-critical systems or high-value products. If the application demands extended product lifecycles, Lead Frames Material C-194 F.H. is a great option due to its high resistance to corrosion and low wear over time. In sectors such as automotive electronics and power electronics, where device failure can have serious consequences, C-194 F.H. ensures that lead frames maintain their integrity and performance throughout the lifespan of the component. -

Cost-Benefit Analysis:

Manufacturers must conduct a cost-benefit analysis to determine if the performance advantages of Lead Frames Material C-194 F.H. justify its higher cost compared to other materials. For high-performance applications, the additional cost of C-194 F.H. is often justified by its superior mechanical strength, electrical conductivity, and thermal properties. However, for applications where performance requirements are more modest, alternative materials may be more suitable in terms of cost efficiency.

When choosing Lead Frames Material C-194 F.H. for specific applications, manufacturers need to carefully consider factors such as performance requirements, cost considerations, and environmental conditions. The material’s superior properties make it an excellent choice for high-performance and high-reliability applications, but its higher cost may not always be justified for more budget-conscious projects. By understanding the current market trends and conducting a thorough suitability assessment, manufacturers can ensure that C-194 F.H. is the right material choice for their semiconductor packaging needs.

FQAs Abut Lead Frames Material C-194 F.H.

What is C194 material?

C194 is a copper alloy, also known as C19400, that contains small amounts of silver (typically around 0.02% to 0.06%) and other elements to enhance its properties. It is known for its excellent electrical and thermal conductivity, high strength, and corrosion resistance, making it a popular choice for lead frames used in semiconductor packaging. C194 is often chosen for its durability and performance in demanding applications such as automotive electronics and LED packaging.

What materials are used in lead frames?

Lead frames are commonly made from copper-based materials, including pure copper, copper alloys (such as C194, C10100, C7025), and brass. These materials are chosen for their electrical conductivity, thermal conductivity, mechanical strength, and corrosion resistance. Sometimes, stainless steel or aluminum may also be used in specific applications, depending on the requirements for strength and environmental resistance.

What is lead frame plating?

Lead frame plating refers to the process of applying a thin coating of a metal, such as gold, silver, or nickel, onto the surface of a lead frame. This plating serves several purposes, including improving corrosion resistance, enhancing solderability, and protecting the material from oxidation. Plating helps ensure that the lead frame can perform reliably over time, particularly in harsh environments or high-performance applications.

What are the parts of a leadframe?

A typical lead frame consists of several key components:

- Lead: The electrical contacts that connect the semiconductor device to the external circuitry.

- Frame: The base structure that holds and supports the leads in the correct alignment during the packaging process.

- Tie bars: Small connections that hold the leads together and help with the packaging process.

- Lids and fins: Additional components that are sometimes included to help with heat dissipation or structural stability.

- Pad and finger: Where the semiconductor die is attached.