Applications of Kyocera’s High-Temperature Substrates

Kyocera Corporation, headquartered in Kyoto, Japan, plays a pivotal role in the global electronics industry. Known for its advanced ceramic technology, Kyocera manufactures a diverse range of products including electronic components, industrial tools, and equipment for telecommunications and automotive sectors. With operations spanning across Asia, Americas, Europe, and beyond, Kyocera boasts extensive market coverage, delivering innovative solutions that cater to high-tech industries worldwide. The company’s commitment to quality and sustainability underscores its leadership in providing reliable components essential for modern electronic applications.

Kyocera Build-up Substrates

Definition and Applications of Build-up Substrates

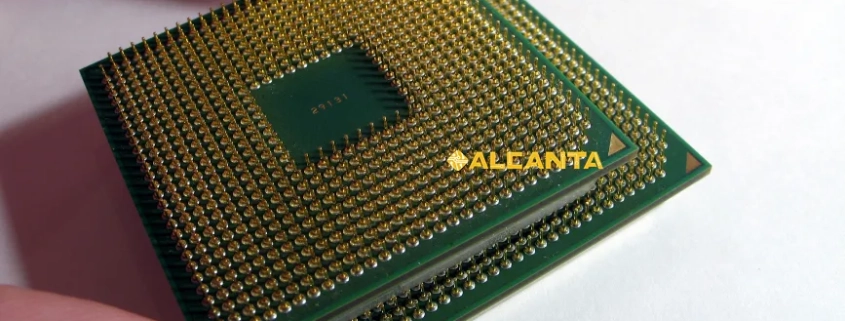

Build-up substrates are advanced PCBs designed with multiple layers of insulating and conductive materials. They enable complex circuitry and miniaturization in electronic devices, supporting high-density interconnects (HDI) and fine pitch components. Kyocera’s build-up substrates integrate precision manufacturing techniques to achieve tight tolerances and reliability in signal transmission and power distribution.

Kyocera’s Technological and Product Advantages in Build-up Substrates

Kyocera excels in build-up substrate technology through its expertise in ceramic materials and microfabrication. Their substrates feature low-loss dielectrics, high thermal conductivity, and excellent mechanical stability, crucial for demanding applications in telecommunications, aerospace, and medical devices. Kyocera’s innovations include customizable designs, ensuring optimal performance in diverse electronic environments.

Real-world Applications and Case Studies

Kyocera’s build-up substrates are integral to smartphones, automotive electronics, and IoT devices. For example, in automotive electronics, they enhance reliability and performance in control modules and infotainment systems. Case studies highlight their role in enabling compact, high-performance solutions that meet stringent industry standards and deliver exceptional reliability in challenging operational environments.

Kyocera Multilayer Ceramic Capacitors (MLCCs)

Basic Principles and Structure of MLCCs

MLCCs are passive electronic components composed of alternating layers of ceramic materials and metal electrodes. They store electrical energy and filter out high-frequency noise in circuits. Kyocera’s MLCCs utilize advanced ceramic formulations and precise layering techniques to achieve high capacitance densities and stable performance across a wide range of temperatures and frequencies.

Kyocera’s Expertise and Technological Advantages in Manufacturing MLCCs

Kyocera leads in MLCC manufacturing due to its deep expertise in ceramic materials and process innovation. Their MLCCs feature low equivalent series resistance (ESR), high reliability, and excellent temperature stability, crucial for applications in consumer electronics, automotive systems, and industrial equipment. Kyocera’s proprietary manufacturing techniques ensure consistent quality and support customization to meet specific customer requirements.

Applications and Market Demand for MLCCs in Electronic Products

MLCCs are essential in smartphones, computers, power supplies, and IoT devices, where they support miniaturization and enhance circuit performance. The market demand for MLCCs continues to grow, driven by increasing electronic device complexity and the need for compact, efficient components. Kyocera’s MLCCs address these demands with robust designs that ensure optimal electrical performance and reliability in diverse applications.

Kyocera Industrial Tools Corporation

Business Scope and Product Types of Kyocera Industrial Tools Corporation

Kyocera Industrial Tools Corporation specializes in providing cutting tools and solutions for various industries, including automotive, aerospace, and electronics manufacturing. Their product range includes precision cutting tools, indexable inserts, and tool holders designed to enhance machining efficiency, accuracy, and tool life. Kyocera’s tools are renowned for their high-performance materials and advanced coatings, which optimize cutting processes in challenging manufacturing environments.

Support Provided by Industrial Tools Corporation in Electronic Manufacturing and Assembly Processes

In electronic manufacturing, Kyocera Industrial Tools Corporation plays a crucial role by offering specialized tools for PCB fabrication, such as drills, end mills, and routers. These tools are essential for precision machining of substrates, ensuring accurate dimensions and surface finishes critical for circuit board assembly. Kyocera’s cutting-edge technologies and application expertise help electronic manufacturers improve throughput, reduce scrap, and maintain stringent quality standards in production lines worldwide.

Kyocera High-Temperature Ceramic Substrates

Importance and Characteristics of High-Temperature Ceramic Substrates

High-temperature ceramic substrates play a critical role in electronic applications where extreme heat resistance, thermal stability, and electrical insulation are essential. These substrates can withstand temperatures ranging from hundreds to thousands of degrees Celsius without degrading, making them ideal for harsh environments and demanding industrial processes. They offer excellent mechanical strength, low thermal expansion, and high dielectric strength, ensuring reliable performance in aerospace, automotive, and industrial applications.

Kyocera’s Ceramic Substrate Technology and Product Features for High-Temperature Electronic Integration

Kyocera excels in high-temperature ceramic substrate technology through advanced material formulations and precise manufacturing processes. Their substrates feature specialized ceramic compositions optimized for thermal conductivity and mechanical robustness. Kyocera utilizes proprietary bonding and layering techniques to create dense, uniform substrates capable of supporting high-power electronics and circuitry in extreme thermal conditions. These substrates enable compact designs and enhance the efficiency and reliability of electronic systems operating in elevated temperatures.

Application Cases in Aerospace, Automotive Electronics, and Industrial Control

Kyocera’s high-temperature ceramic substrates are integral to aerospace applications such as satellite communications, where they ensure stable performance of onboard electronics in space environments. In automotive electronics, these substrates support power modules and sensors that operate in engine compartments, withstanding thermal cycling and vibrations. In industrial control systems, they enable the reliable operation of high-power electronics in factories and power plants, enhancing equipment efficiency and longevity. Kyocera’s ceramic substrates contribute to advancing technology in critical sectors by enabling robust electronic integration under challenging thermal conditions.

FAQs about kyocera substrate

No, Kyocera is not a Chinese company. It is a Japanese multinational corporation.

The substrate used in electronic packaging can vary, but common types include FR4 (fiberglass-reinforced epoxy laminate), ceramics, and various specialized materials designed for specific applications.

A ceramic substrate is a type of base material used in electronics, made from ceramic materials that offer advantages such as high thermal conductivity, electrical insulation, and mechanical stability.

Ceramic substrates for high-temperature electronic integration are designed to withstand extreme heat conditions, providing thermal management and reliability for electronic components in aerospace, automotive, and industrial applications.