Material Insights: ABF vs. BT Resin vs. Ceramics in IC Substrate

IC Substrate, or Integrated Circuit Substrate, serves as a critical component in modern electronic devices. It functions as a bridge, connecting semiconductor chips to the printed circuit board (PCB) while enabling electrical signal transmission and mechanical support. As the demand for compact and high-performance electronic products grows, IC Substrates have become indispensable in achieving miniaturization and enhanced functionality.

These substrates are engineered to support high-density interconnects (HDI), offering solutions for efficient heat dissipation, signal integrity, and power delivery. With their advanced multilayer designs, IC Substrates facilitate the integration of increasingly complex circuits in limited spaces, making them essential for devices like smartphones, laptops, automotive electronics, and IoT applications.

What is IC Substrate?

IC Substrate, or Integrated Circuit Substrate, is a specialized base material that serves as the intermediary between the semiconductor chip and the printed circuit board (PCB). Its primary function is to provide a stable platform for the chip, enabling electrical signal transmission, mechanical support, and efficient thermal management. The substrate ensures reliable connectivity by accommodating the intricate wiring and interconnects required for advanced electronic devices.

IC Substrates play a critical role in supporting high-density circuits and enabling the miniaturization of modern electronics. By incorporating multilayer designs and fine circuit patterns, they allow for compact, lightweight devices without compromising performance. These substrates are pivotal in applications like smartphones, laptops, automotive systems, and IoT devices, where space is limited, and performance demands are high.

As a cornerstone of innovation, IC Substrates bridge the gap between complex chips and external systems, ensuring the functionality and efficiency of cutting-edge technology.

Why IC Substrates Enable Miniaturization

IC Substrates are fundamental in enabling the miniaturization of modern electronic devices. One of their key advantages lies in their ability to support high-density wiring. With advanced manufacturing processes, IC Substrates accommodate intricate interconnects, allowing for more circuits to be integrated into a smaller area. This high-density capability is essential for compact electronic products like smartphones, wearables, and IoT devices.

Breakthroughs in miniaturization are further driven by the development of multilayer designs and finer circuit patterns. These multilayer substrates enable vertical stacking of circuits, maximizing the use of limited space while maintaining performance. At the same time, the precision of finer patterns ensures that signals can travel efficiently without interference, even in densely packed environments.

In addition to spatial efficiency, IC Substrates excel in thermal management and maintaining electrical signal integrity. By effectively dissipating heat and minimizing signal loss, they ensure reliable performance in high-power and high-frequency applications, making them indispensable for today’s electronics.

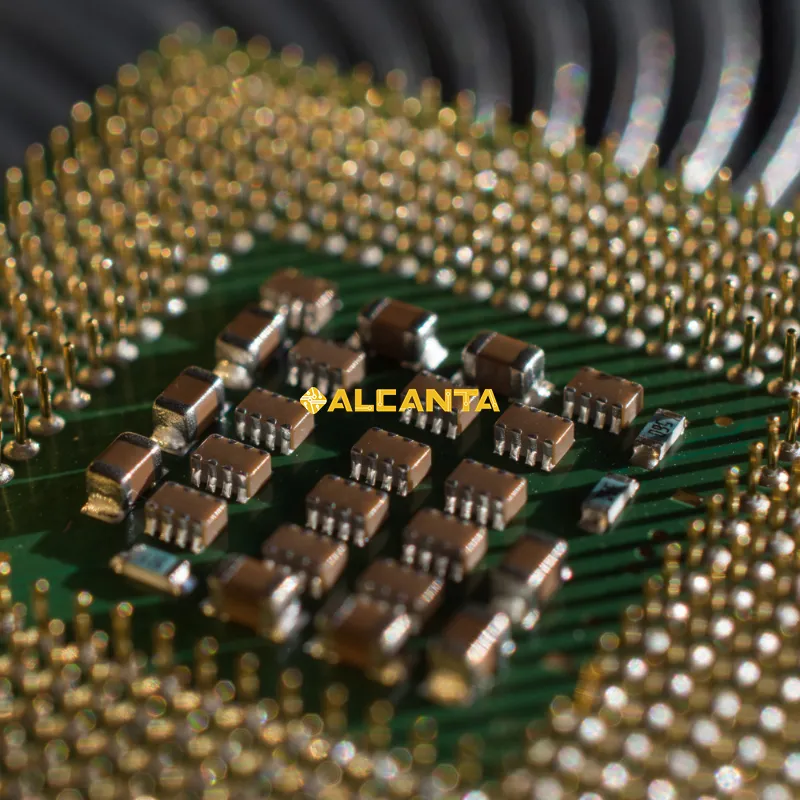

Materials Used in IC Substrates

The materials used in IC Substrates play a crucial role in determining their performance and suitability for various applications. Common materials include BT resin, ABF materials, and ceramics, each offering distinct advantages.

BT Resin (Bismaleimide-Triazine):

Known for its excellent thermal stability and mechanical strength, BT resin is widely used in applications requiring durability and reliability, such as automotive electronics and industrial devices. It provides good electrical insulation and is cost-effective for many standard packages.

ABF Materials (Ajinomoto Build-up Film):

ABF materials excel in supporting high-density interconnects (HDI) due to their ability to enable fine circuit patterns and multilayer structures. They offer excellent electrical performance with low dielectric loss, making them ideal for advanced computing and networking applications, such as CPUs and GPUs.

Ceramics:

Ceramics provide exceptional thermal conductivity and mechanical strength, making them suitable for high-power and high-frequency applications, including RF modules and LED packaging. Their low thermal expansion coefficient ensures stability in extreme operating conditions.

The careful selection of these materials allows IC Substrates to meet the diverse needs of modern electronics while optimizing performance and reliability.

Why Automated IC Substrate Design is Crucial

Automated IC Substrate design is essential in managing the increasing complexity of modern electronic devices. With the demand for higher performance and compact designs, manual approaches are no longer sufficient to meet industry requirements.

Automation tools play a vital role in supporting complex IC Substrate designs. They ensure accurate modeling of intricate circuits and interconnects while optimizing for critical factors such as signal integrity and thermal performance. For example, automated simulations can identify potential signal interference issues or thermal hotspots, enabling designers to address these challenges early in the development process. This not only enhances the substrate’s functionality but also ensures reliability in high-performance applications.

Additionally, automation significantly reduces design errors, minimizing costly revisions and delays. By streamlining processes like layer stacking and routing, it accelerates production timelines while maintaining precision. This improved efficiency allows manufacturers to meet tight deadlines and scale production effectively, making automation indispensable for IC Substrate design.

Key Considerations in IC Substrate Design

Designing an IC substrate requires addressing several key factors to ensure optimal performance and reliability. The following are key considerations for successfully designing an IC substrate:

Signal and Power Integrity

Signal and power integrity are fundamental to high-performance devices. Designers must minimize signal loss, crosstalk, and noise to ensure reliable data transmission. This involves precise impedance control and maintaining uniform transmission line characteristics across the substrate. Adequate power delivery networks (PDNs) are also necessary to stabilize voltage levels and reduce power supply noise, which is especially important for high-frequency and high-speed applications. Effective decoupling capacitor placement and proper grounding are necessary strategies to enhance signal and power integrity.

Thermal Management

Efficient heat dissipation is critical for IC substrates, especially in high-power density applications such as CPUs, GPUs, and automotive electronics. Poor thermal management can lead to overheating, performance degradation, or device failure. To address this, designers must select materials with high thermal conductivity, such as ceramic or copper layers, and incorporate thermal vias or heat sinks into the substrate. Advanced simulations are often used to predict thermal behavior and optimize layouts for efficient heat transfer.

Balancing Wiring Density and Layer Stack Design

IC substrates require high wiring density to accommodate complex circuits in limited space. This typically involves a multilayer design where circuits are stacked vertically to save space. However, balancing routing density and manufacturability is a challenge. Excessive miniaturization leads to routing difficulties and increased risk of signal interference. Designers must carefully optimize the layer stack to include sufficient ground and power planes, ensuring structural stability and electrical performance without complicating the manufacturing process. Advanced tools and design rules are used to effectively achieve this balance.

By addressing these issues, IC substrate designs can achieve the high-performance standards required for today’s cutting-edge electronic devices while maintaining reliability and manufacturability.

Key Parameter in IC Packaging: Ball Pitch

Ball pitch refers to the distance between the centers of adjacent solder balls on a Ball Grid Array (BGA) package. It is a critical parameter in IC packaging, as it directly influences the layout, performance, and manufacturability of the IC Substrate.

Definition and Significance

The ball pitch determines the spacing of the solder balls that connect the IC Substrate to the printed circuit board (PCB). Smaller ball pitches enable higher interconnect density, allowing for more signals to pass through a compact area. This is essential for miniaturizing electronic devices while maintaining functionality. For advanced applications like CPUs, GPUs, and high-performance networking devices, finer ball pitches are necessary to meet the increasing demands for speed and processing power.

Impact on Manufacturing Processes and Reliability

Reducing the ball pitch increases design and manufacturing complexity. It requires precise alignment and advanced fabrication techniques to ensure consistent soldering quality. Smaller pitches also demand substrates with high-density interconnects (HDI) and tighter design tolerances, which can raise production costs.

From a reliability perspective, a reduced ball pitch can increase the risk of solder joint failure due to thermal expansion mismatches or mechanical stress. Therefore, robust design strategies and material selection are crucial to ensure the long-term durability of the package.

Overall, optimizing ball pitch is a balancing act between achieving high performance and maintaining manufacturability and reliability in IC Substrate design.

Main Characteristics of IC Substrates

IC Substrates are engineered to meet the rigorous demands of modern electronics, combining precision, stability, and high electrical performance to ensure reliable functionality in complex devices. Below are the main characteristics of IC Substrates:

Precision: High-Density Wiring Capabilities

One of the defining features of IC Substrates is their ability to support high-density wiring, which is crucial for integrating more components in smaller packages. Precision manufacturing processes enable the creation of fine circuit patterns with minimal space between interconnects. This capability allows IC Substrates to accommodate a large number of signal and power connections in a compact area, facilitating miniaturization and improving the overall functionality of modern devices. The ability to achieve fine trace widths and tight pitch between pads ensures that even advanced chips, like microprocessors and memory modules, can be efficiently connected without compromising performance.

Stability: Matching Thermal Expansion Coefficients and Ensuring Durability

Thermal stability is a key factor in the design of IC Substrates, particularly in high-performance applications. These substrates must match the thermal expansion coefficients of both the chip and the PCB to prevent warping or cracking due to temperature fluctuations during operation. Materials with low thermal expansion are commonly used to ensure that the substrate remains stable throughout its lifespan, even under harsh thermal cycles. Additionally, IC Substrates must be durable enough to withstand mechanical stress and provide long-term reliability in electronic systems. This stability is crucial for ensuring that the IC operates effectively over time without degradation or failure.

Electrical Performance: Low Loss and High-Speed Signal Transmission

IC Substrates are designed to provide exceptional electrical performance, particularly in high-speed and high-frequency applications. They offer low signal loss, which is essential for maintaining the integrity of data transmission in devices like processors, communication systems, and networking equipment. The materials used in IC Substrates are selected for their ability to minimize dielectric loss and reduce signal degradation. By ensuring that the signals travel quickly and with minimal resistance, IC Substrates enable fast data processing and contribute to the overall speed and efficiency of modern electronics.

The main characteristics of IC Substrates — precision, stability, and high electrical performance — ensure that they meet the ever-increasing demands of electronic devices, allowing for reliable, high-performance operation in compact and complex designs.

Wiring Challenges in IC Substrates

As IC Substrates evolve to support increasingly complex and high-performance electronics, wiring challenges have become more pronounced. High-density wiring, essential for miniaturizing devices, introduces several difficulties that need careful consideration. Below are some of the main wiring challenges faced in IC Substrates:

Signal Crosstalk and Impedance Control in High-Density Wiring

With the increase in the number of interconnections on IC Substrates, signal crosstalk becomes a significant concern. Crosstalk occurs when signals from adjacent wires interfere with each other, potentially leading to data corruption, signal degradation, or malfunction. This issue is particularly prominent in high-density wiring, where the circuits are tightly packed in a limited space.

To mitigate signal crosstalk, careful impedance control is necessary. Impedance mismatch between traces and the PCB can result in signal reflection or distortion. Therefore, designers must ensure that the impedance of each signal trace is matched to the source and load, which requires precise calculation of trace width, spacing, and material properties. Advanced simulation tools are commonly used to predict and correct these issues during the design process, ensuring reliable performance even in high-speed applications.

Technical Difficulties Due to Increased Complexity and Miniaturization

As electronic devices become more compact, the complexity of the wiring within IC Substrates also increases. The need to integrate more components into smaller spaces while maintaining signal integrity leads to challenges in routing high-density interconnections. Miniaturization limits the available area for wiring, forcing designers to stack multiple layers or use smaller traces and vias, which complicates the overall layout.

The smaller the design, the more challenging it is to maintain manufacturing precision. Fine-pitch components require tight tolerances to avoid misalignment or poor soldering during assembly. Additionally, miniaturized designs are prone to issues such as increased resistance, reduced heat dissipation, and potential for signal interference. To address these challenges, advanced techniques like via-in-pad technology, micro-vias, and advanced materials with lower dielectric constants are employed to support high-density, high-speed applications without compromising performance.

Overall, the wiring challenges in IC Substrates reflect the trade-offs between high-performance design, miniaturization, and manufacturing feasibility. Careful attention to impedance control, crosstalk mitigation, and overcoming the technical difficulties associated with increased complexity is essential for achieving reliable, high-functioning IC Substrates.

Overview of IC Substrate Materials

The selection of materials for IC Substrates is crucial in determining their performance, reliability, and cost. The three main types of materials commonly used in IC Substrates are ABF (Ajinomoto Build-up Film), BT resin (Bismaleimide-Triazine), and ceramics. Each material has unique properties that make it suitable for different applications, and understanding these differences is essential when designing high-performance substrates. Below is an overview of the key material types used in IC Substrate construction:

ABF (Ajinomoto Build-up Film)

Pros:

ABF is a popular material choice for high-performance IC Substrates, particularly for advanced semiconductor packaging. It offers excellent dielectric properties, ensuring low signal loss and high-speed signal transmission, which are essential for high-density circuits. ABF also provides good thermal stability, making it suitable for power-sensitive applications.

Cons:

ABF is typically more expensive compared to other materials like BT resin. Additionally, its processing can be more complex, requiring specialized fabrication techniques. This can increase production time and cost.

Impact on Cost and Performance:

While ABF materials can add to the overall cost of production, their high electrical performance and low signal loss make them an ideal choice for cutting-edge devices such as CPUs and memory modules, where high-speed operation is a priority.

BT Resin (Bismaleimide-Triazine)

Pros:

BT resin is a widely used material in IC Substrate fabrication due to its good thermal stability, electrical insulation, and mechanical strength. It is particularly favored in the production of substrates for mid-range to high-performance devices. BT resin offers good balance between performance and cost, making it a versatile choice for a variety of applications.

Cons:

BT resin generally has a lower thermal conductivity compared to ceramics, making it less suitable for high-power applications. It also tends to have a higher dielectric loss than ABF, which can affect signal quality in high-frequency designs.

Impact on Cost and Performance:

BT resin provides a more cost-effective solution than ABF, offering a good compromise between performance and expense. It is well-suited for less demanding applications but can be a limiting factor in high-performance or high-frequency IC Substrates where superior signal integrity and thermal management are needed.

Ceramics

Pros:

Ceramic materials, such as alumina and aluminum nitride, are prized for their exceptional thermal conductivity, making them ideal for high-power applications where heat dissipation is critical. Ceramics also offer excellent mechanical strength, durability, and electrical insulation properties. These characteristics make ceramics a preferred choice for substrates in power electronics and optoelectronics.

Cons:

The primary drawback of ceramics is their cost and manufacturing complexity. Ceramic substrates require advanced processing techniques, and their brittle nature can make them challenging to handle during assembly. Furthermore, their relatively low flexibility can be a disadvantage in applications that require bending or reshaping.

Impact on Cost and Performance:

Ceramic materials tend to be more expensive than organic materials like BT resin and ABF, both in terms of material costs and the processing involved. However, their superior thermal and mechanical properties make them indispensable in high-power applications, such as power modules, LED packages, and automotive electronics, where heat management and durability are crucial.

The choice of material for IC Substrates significantly affects both performance and cost. ABF materials are ideal for high-speed, high-density applications but come with a higher price tag. BT resin offers a more cost-effective solution with good performance for a variety of applications, while ceramics are the go-to choice for high-power, thermally demanding environments. The final decision will depend on the specific requirements of the application, balancing the need for performance with the constraints of cost and manufacturability.

IC Substrate Assembly Process Challenges

The assembly process of IC Substrates is critical in ensuring the performance and reliability of electronic devices. Despite advancements in materials and design, various challenges persist during the assembly of IC Substrates, particularly in mounting techniques such as ball grid array (BGA) reflow. Below are the key challenges faced during the assembly process and methods used to address them:

Common Issues in Mounting Techniques like Ball Grid Array (BGA) Reflow

Ball Grid Array (BGA) is one of the most widely used packaging technologies for IC Substrates, especially for high-density interconnects. During the BGA reflow process, small solder balls are placed on the substrate’s surface and then melted under heat to form the solder joints that connect the IC chip to the substrate. While this process is efficient and effective for high-performance applications, it comes with several potential issues:

- Solder Joint Misalignment: During the BGA reflow process, it’s crucial to ensure the precise alignment of the solder balls with the pads on the substrate. Any misalignment can result in weak or faulty connections, potentially causing the device to fail.

- Void Formation: Voids in solder joints can form when gas gets trapped during the reflow process. These voids reduce the strength of the solder joint, affecting the long-term reliability of the connection and leading to potential mechanical or electrical failures.

- Overheating and Delamination: Excessive temperatures during reflow can cause damage to the substrate, particularly in sensitive materials like ABF. Overheating can lead to warping, delamination, or cracking of the substrate, negatively impacting its performance and reliability.

To mitigate these challenges, precise temperature control, accurate placement of solder balls, and advanced inspection methods (such as X-ray imaging) are used to detect alignment issues and voids before final assembly.

Ensuring Connection Reliability and Solder Joint Quality

Connection reliability and solder joint quality are essential for the long-term functionality of IC Substrates. The integrity of the solder joints is critical for ensuring stable electrical connections, particularly in high-performance systems with high-speed data transmission. Several factors influence the reliability and quality of solder joints:

- Solder Material Selection: The choice of solder material plays a key role in ensuring the strength and durability of the connections. For high-performance applications, lead-free solders and high-melting-point materials are often used to prevent joint degradation under thermal cycling.

- Reflow Process Control: Controlling the reflow process, including the heating rate, peak temperature, and cooling profile, is essential to ensuring uniform solder joint formation. Variations in these parameters can lead to inconsistent solder joints, compromising both electrical performance and mechanical reliability.

- Surface Preparation: Proper cleaning and surface preparation of both the BGA and substrate are vital to ensure good wetting during soldering. Contaminants such as flux residues or oxides can prevent the solder from bonding effectively, leading to weak joints and poor electrical conductivity.

To enhance connection reliability, automated inspection systems, such as automated optical inspection (AOI) and X-ray inspection, are used to monitor solder joint quality and ensure they meet the required standards. These technologies enable early detection of defects and improve the overall yield of the assembly process.

The assembly process of IC Substrates, particularly when using mounting techniques like BGA reflow, presents several challenges that must be addressed to ensure connection reliability and the quality of solder joints. Proper alignment, control of the reflow process, and the selection of suitable solder materials are essential for achieving durable and reliable connections. By implementing precise process controls and advanced inspection techniques, manufacturers can overcome these challenges and deliver high-performance IC Substrates for a wide range of electronic applications.