From QFP to QFN: A Visual Guide to Common IC Package Types

IC packaging is pivotal, ensuring device functionality and reliability. Serving as a protective shield for precision IC components, it guards against external elements and mechanical stress. As a crucial bridge between intricate semiconductor designs and practical manufacturing needs, IC packaging facilitates connectivity, thermal management, and system integration. Effective packaging not only dissipates heat efficiently but also influences electrical characteristics, signal integrity, and overall reliability, directly impacting a device’s market success.

In parallel, the evolution of IC substrate involves high-speed, high-frequency material packaging substrates. Advanced production processes and technologies drive the development of substrates, further enhancing the performance and capabilities of integrated circuits.

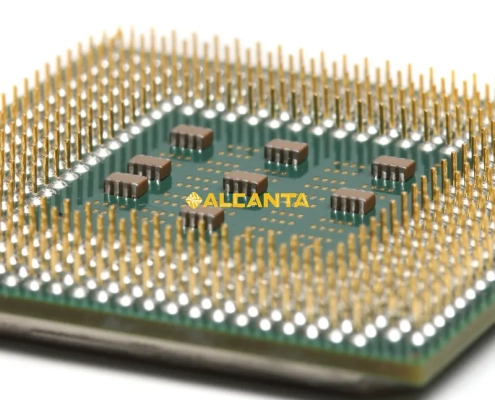

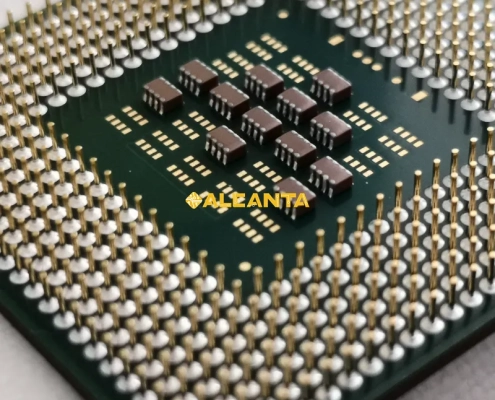

Overview of IC Package

What is an IC Package?

An Integrated Circuit (IC) Package is the protective housing that encapsulates the semiconductor die and associated components, forming a complete and functional unit. This encapsulation shields the delicate IC from environmental factors, mechanical stress, and electromagnetic interference, ensuring its integrity and functionality.

Basic Components and Functions of IC Package

The IC Package comprises various components, including the substrate, die attach material, wire bonds or interconnects, and encapsulating materials. The substrate provides a foundation for the die, and the die attach material securely affixes the semiconductor die to the substrate. Wire bonds establish electrical connections between the die and external leads, facilitating signal transmission. Encapsulating materials shield the entire assembly, providing protection against moisture, contaminants, and mechanical damage.

Role of IC Package in Circuit Design

In circuit design, the IC Package plays a crucial role in shaping the electrical and thermal characteristics of the integrated circuit. It influences signal integrity, power distribution, and thermal management. The package also determines the method of connection to the external circuit, affecting the overall performance of the device. Designers must consider the electrical properties of the package, such as capacitance and inductance, to ensure optimal signal transmission and minimize interference. Additionally, the thermal characteristics of the package impact the efficiency and reliability of the circuit, making the selection of an appropriate IC Package a critical aspect of successful circuit design.

Types of IC Packages

| IC Package Type | Description |

| Dual In-line Package (DIP) | One of the earliest IC package types, characterized by two parallel rows of pins along the longer edges. Commonly used in through-hole mounting, offering ease of soldering and repair. |

| Quad Flat Package (QFP) | A surface-mount IC package with pins arranged in a grid pattern around the periphery of the package. Available in various sizes and pin counts, suitable for a wide range of applications including microcontrollers, memory chips, and ASICs. |

| Small Outline Integrated Circuit (SOIC) | A surface-mount IC package with gull-wing leads extending from two sides of the package. It offers a smaller form factor compared to DIP packages and is commonly used in consumer electronics and compact devices. |

| Plastic Leaded Chip Carrier (PLCC) | A square or rectangular IC package with leads extending from all four sides. Made of plastic, it offers improved heat dissipation compared to ceramic packages and is commonly used in applications where thermal management is crucial. |

| Quad Flat No-leads (QFN) | A compact IC package with no leads extending from the bottom surface. It features exposed pads for electrical connections and is widely used in space-constrained applications due to its low profile and efficient heat dissipation. |

| Ball Grid Array (BGA) | A grid of solder balls arranged on the underside of the package, providing electrical connections to the PCB. BGA packages offer high pin counts, compact size, and improved thermal performance, making them suitable for high-density applications such as microprocessors and GPUs. |

IC Package Substrate and Design

IC Die and Package

Importance of IC Package

Impact of IC Package on Electronic Product Performance

The IC Package plays a pivotal role in shaping the overall performance of electronic products. The package directly influences key parameters such as thermal management, signal integrity, and reliability. Efficient heat dissipation, facilitated by the right package, ensures that the integrated circuit operates within the specified temperature range, preventing overheating that could degrade performance and lifespan. The electrical characteristics of the package impact signal propagation, minimizing signal loss and interference for enhanced signal integrity. These factors collectively contribute to the product’s reliability, functionality, and overall performance.

Advantages of Choosing the Right IC Package

Selecting the appropriate IC Package offers several advantages that directly translate into improved product outcomes.

- Enhanced Reliability: A well-chosen IC Package provides robust protection for the semiconductor die, shielding it from environmental factors and mechanical stress. This enhances the reliability and durability of the electronic product, especially in challenging operating conditions.

- Optimized Thermal Management: The right package design ensures efficient heat dissipation, preventing thermal issues that can degrade performance. Improved thermal management contributes to the longevity and consistent operation of the integrated circuit.

- Improved Signal Integrity: Proper package selection minimizes electrical interference and signal degradation, promoting superior signal integrity. This is particularly crucial in high-frequency applications and complex circuit designs where maintaining precise signal transmission is paramount.

- Space Efficiency: Certain package types, like smaller form-factor packages, contribute to space-efficient designs. This is essential in modern electronics where compactness is a key consideration, allowing for sleeker and more portable devices.

Role of IC Package in Innovation

The IC Package serves as an enabler for innovation in the electronics industry.

- Miniaturization: Advances in package design contribute to the ongoing trend of miniaturization. Smaller, more efficient packages allow for the creation of compact and lightweight electronic devices, fostering innovation in industries such as wearables, IoT, and mobile technology.

- Integration of Advanced Technologies: Innovations in IC packaging techniques facilitate the integration of advanced technologies. This includes features like System-in-Package (SiP), enabling the combination of multiple functions within a single package, fostering advancements in multifunctional and high-performance devices.

- Customization for Diverse Applications: The versatility in IC Package designs enables customization for specific applications. Tailoring packages to meet the unique requirements of diverse industries, from automotive to medical devices, promotes innovation by addressing specific challenges and demands.

In essence, the right IC Package is not just a protective housing; it is a key determinant of a product’s reliability, efficiency, and adaptability to technological advancements, thereby playing a crucial role in driving innovation within the electronic industry.

Visual Representation of IC Package Types

Real-world Applications of IC Package

Showcase Products Using Specific IC Package Types

In real-world applications, specific IC Package types are strategically chosen to enhance the performance and reliability of various electronic products. Let’s delve into some notable examples:

- Automotive Control Units (ACUs) with QFP

- QFP packages are frequently employed in automotive control units, ensuring robust connectivity and efficient heat dissipation. The reliability of these packages is crucial in the demanding automotive environment.

- Communication Devices with SOIC

- SOIC packages find extensive use in communication devices, providing a compact and reliable solution. Their small form factor is ideal for applications such as modems, routers, and networking equipment.

- Industrial Sensors with PLCC

- PLCC packages are preferred for industrial sensors where thermal management is critical. The plastic casing offers durability, and the package design contributes to efficient heat dissipation.

- Consumer Electronics with QFN

- QFN packages are commonly found in consumer electronics like smartphones and tablets due to their space-efficient design. The absence of leads contributes to a sleek profile, and their low thermal resistance is advantageous in compact devices.

Analysis of the Impact of IC Package on Product Performance

The choice of IC Package profoundly influences the performance of electronic products. For instance:

- The thermal characteristics of the package directly impact the performance of high-power applications, preventing overheating and maintaining operational stability.

- Signal integrity, influenced by the electrical properties of the package, is crucial in applications demanding precise signal transmission, such as high-speed data communication.

A comprehensive analysis of the impact of IC Packages on product performance involves evaluating factors like power efficiency, reliability, and overall functionality. This analysis guides designers in selecting the most suitable package for specific application requirements.

Sharing Success Stories from the Industry

Industry success stories highlight the significance of choosing the right IC Package. For instance:

- The adoption of advanced IC Packages in medical devices has contributed to breakthroughs in diagnostic equipment, ensuring accuracy and reliability in critical healthcare applications.

- In the aerospace sector, the utilization of robust IC Packages has enhanced the performance and durability of avionics systems, contributing to the safety and efficiency of air travel.

These success stories underscore the role of IC Packages in enabling innovation, improving product performance, and driving advancements across diverse industries. They serve as testimonials to the importance of thoughtful package selection in achieving success in real-world applications.

Future Trends in IC Package Development

FAQs About IC package

What is the IC package?

The IC package, or Integrated Circuit package, refers to the protective enclosure that houses the semiconductor die and associated components, forming a complete and functional unit. It shields the delicate IC components from external elements and mechanical stress while providing electrical connectivity and thermal management.

What does IC mean on a package?

On a package, “IC” stands for Integrated Circuit. It indicates that the package contains an integrated circuit, which is a miniaturized electronic circuit consisting of semiconductor devices such as transistors, resistors, and capacitors fabricated onto a single semiconductor substrate.

What does IC mean in packaging?

In the context of packaging, “IC” still refers to Integrated Circuit. It signifies that the packaging contains a complete integrated circuit, encapsulated within the package for protection and ease of handling during assembly and integration into electronic devices.

What is flat package IC?

A flat package IC refers to an integrated circuit package with a low profile and a flat surface. These packages typically have no leads protruding from the bottom, which contributes to their compact design. Examples of flat package ICs include Quad Flat No-leads (QFN) and Small Outline Integrated Circuit (SOIC) packages. They are commonly used in applications where space-saving and thermal performance are crucial.