Glass Substrate in Semiconductor Packaging: Pros and Cons

Glass substrate are emerging as a transformative material in semiconductor packaging and high-frequency PCB applications. With superior properties such as ultra-low thermal expansion (CTE), high flatness, and excellent dielectric performance, glass substrates offer significant advantages over traditional organic and silicon-based materials. Companies like Intel are pioneering glass core substrates, enabling higher I/O density, improved signal integrity, and better thermal stability for AI, HPC, and 5G applications. Additionally, through-glass via (TGV) technology enhances high-density interconnects, making glass substrates ideal for 2.5D/3D packaging and RF devices. As demand for faster, more efficient semiconductor solutions grows, glass substrates are set to play a crucial role in the future of advanced packaging and next-generation computing.

what is glass substrate?

Glass substrates are ultra-flat, highly stable materials used in semiconductor packaging and high-frequency electronics. They offer:

- High flatness: Supports fine-line circuit patterning

- Low CTE: Matches silicon chips, reducing warpage

- Low dielectric loss: Improves signal integrity for high-speed applications

Comparison: Glass Substrate vs. Traditional Semiconductor Substrates

- Organic (ABF, BT): Cost-effective but prone to warpage and limited in fine-line capability

- Silicon: Excellent performance but expensive and difficult to scale

- Ceramic: High stability but brittle and costly

- Glass: Combines low CTE, high flatness, and low loss, making it ideal for advanced packaging

Importance in Semiconductor Packaging and High-Frequency PCBs

Glass substrates enable:

- Higher interconnect density for advanced chip packaging

- Better signal performance in 5G, AI, and RF applications

- Improved reliability in 2.5D/3D and chiplet architectures

- Scalability for larger panels, reducing production costs

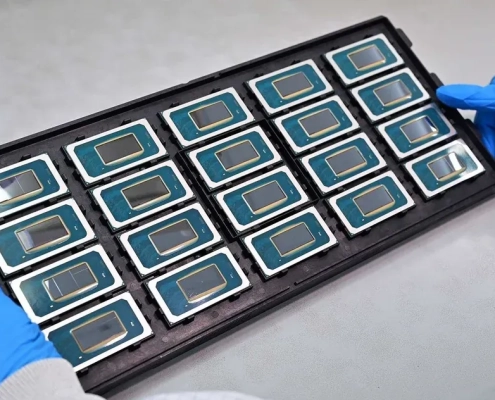

Background of Intel’s Glass Core Substrate Development

Intel’s Glass Core Substrate is designed to meet the growing demand for higher performance in semiconductor packaging. This development is part of Intel’s focus on advancing chiplet-based packaging and 3D architectures, offering better heat management, higher density, and enhanced reliability.

Technical Advantages of Intel Glass Substrate

- Higher I/O Density: Supports AI and HPC applications by enabling higher I/O connections in a smaller space.

- Enhanced Thermal Stability: Reduces warpage, providing greater reliability in large-area packaging.

- Low Dielectric Loss: Ideal for 5G communications and other high-speed data transfer applications.

Higher I/O Density for AI and High-Performance Computing (HPC)

Intel’s glass substrate allows for high-density interconnects, which is critical for the data processing needs of AI and HPC.

Enhanced Thermal Stability, Reduced Warpage for Large-Area Packaging

The glass core’s low CTE helps reduce warpage, making it ideal for 2.5D/3D packaging technologies and ensuring reliable performance in larger, complex chip designs.

Low Dielectric Loss, Ideal for 5G Communications

Intel’s glass substrates provide low dielectric loss, enhancing signal integrity and making them well-suited for high-frequency applications such as 5G networks.

Comparison: Intel Glass Substrate vs. Traditional Organic Substrates (ABF, BT Resin)

Intel’s glass substrates outperform organic substrates in thermal stability, dielectric performance, and I/O density, making them more suitable for demanding applications like AI, HPC, and 5G.

Potential Applications of Intel Glass Substrates

- Data Centers: Enables high-speed, high-density interconnects and improved thermal management.

- AI Chips: Supports the high data throughput needed for AI applications.

- Chiplet Packaging: Perfect for chiplet-based architectures, allowing for scalable and flexible chip designs.

Low Dielectric Constant (Dk) & Low Dielectric Loss (Df): Optimized for High-Speed Signal Transmission

Glass substrates offer a low dielectric constant (Dk) and low dielectric loss (Df), making them ideal for high-speed signal transmission applications such as 5G, AI, and data centers. These properties help minimize signal degradation, reduce power consumption, and improve overall communication speeds by maintaining signal integrity even at high frequencies.

Ultra-Low Coefficient of Thermal Expansion (CTE): Matching Silicon Chips for Enhanced Reliability

Glass substrates have an ultra-low coefficient of thermal expansion (CTE), which closely matches the CTE of silicon chips. This property ensures that thermal stress is minimized during heating and cooling cycles, enhancing reliability and reducing the risk of warping or cracking, which is crucial for advanced packaging.

High Flatness and Low Warpage: Enabling Fine-Line Processing (SAP/MSAP)

The high flatness and low warpage of glass substrates provide a stable surface for fine-line processing, such as SAP (Semi-Additive Process) and MSAP (Modified Semi-Additive Process). This makes it possible to produce high-density interconnects with extremely fine lines, essential for high-performance computing and advanced semiconductor packaging.

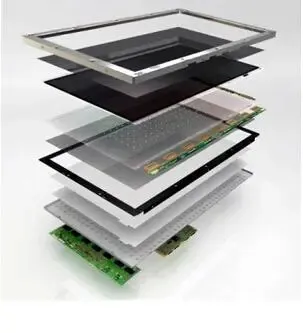

Compatibility with Existing Semiconductor Packaging Processes

Glass substrates are highly compatible with existing semiconductor packaging processes, including flip-chip bonding, wire bonding, and chiplet integration. Their stable mechanical properties and high precision make them easy to integrate into current semiconductor manufacturing workflows, providing a seamless transition for manufacturers seeking to improve performance without overhauling their entire process.

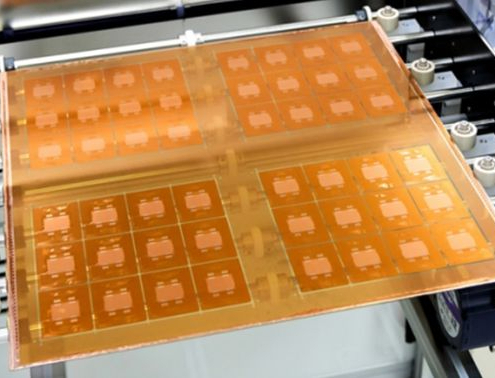

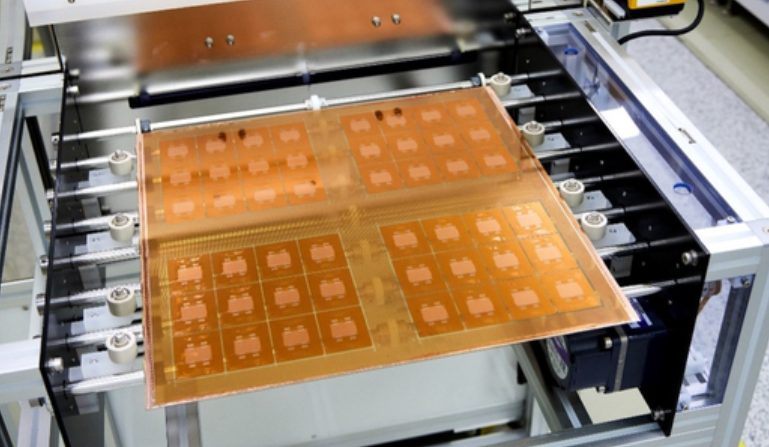

Manufacturing and Processing of Glass Substrate

Glass Cutting and Grinding (Ultra-thin processing <100μm)

Glass substrates are precision-cut and ground to achieve ultra-thin thicknesses below 100μm, ensuring they meet the requirements for advanced packaging without compromising strength or electrical performance.

Through-Glass Via (TGV) Processing (Laser Drilling vs. Chemical Etching)

TGVs are created using laser drilling for precision or chemical etching for uniformity. Both methods enable vertical interconnections, which are key for high-density chip integration in 3D packaging.

Metallization Processes (Sputtering, PVD, CVD, Electroless Plating, Electroplating)

Metallization techniques like sputtering, PVD, and CVD deposit thin metal layers, while electroless plating and electroplating provide thicker, more durable layers for electrical connections, essential for high-performance applications.

Fine-Line Patterning (SAP vs. mSAP): Achieving High-Density Interconnects

Fine-line patterning techniques such as SAP and mSAP enable high-density interconnects on glass substrates, allowing for more compact and efficient semiconductor packaging.

Advanced Packaging Integration (Intel Glass Core Substrate)

Glass substrates support chiplet integration and 3D packaging, with Intel’s Glass Core Substrate offering improved thermal management, higher I/O densities, and reduced warpage for next-generation semiconductor packaging.

Market Trends and Supply Chain of Glass Substrates

Market Growth

The glass substrate market is expanding rapidly, driven by the increasing demand for advanced semiconductor packaging in HPC, 5G, and AI applications. As chip designs become more complex, glass substrates provide a solution with high-density interconnects and improved signal integrity. Technologies like through-glass vias (TGV) and fine-line patterning are enhancing integration capabilities, making glass a key material for next-generation packaging.

Key Players

Major companies in the glass substrate industry include Intel, Corning, Absolics, DNP, SKC, and TSMC. Intel is leading in glass core substrates for chiplet-based packaging, while Corning focuses on high-performance glass materials. Absolics, DNP, and SKC are developing substrates with improved electrical and thermal properties, and TSMC is exploring glass-based solutions for high-performance semiconductor packaging.

Production Challenges

Despite its advantages, mass production of glass substrates faces several challenges. Achieving precise manufacturing at scale is difficult due to the fragility of glass and the complexity of processing techniques like TGV and fine-line patterning. The cost of high-performance glass remains a concern compared to organic or silicon-based substrates. Ensuring high yield rates and process compatibility with existing semiconductor packaging infrastructure is critical for wider adoption.

Future Outlook

Advancements in glass substrate technology will focus on reducing dielectric loss, increasing interconnect density, and enabling larger substrate sizes. These improvements will support the growing needs of AI chips, data centers, and high-frequency applications. As manufacturing processes mature and costs decrease, glass substrates are expected to become a mainstream solution for advanced semiconductor packaging.

Contact Us NOW

FAQs About Glass Substrate

What is a glass substrate?

A glass substrate is a thin, flat layer of glass used as a base material for semiconductor devices, particularly in packaging applications. It provides electrical insulation, stability, and support for components like integrated circuits and microchips.

Why are glass substrates used in semiconductor packaging?

Glass substrates are used in semiconductor packaging due to their low dielectric constant, high flatness, low coefficient of thermal expansion (CTE), and excellent thermal stability, making them ideal for high-density interconnects and high-frequency applications.

What are the key benefits of glass substrates over traditional semiconductor substrates?

Glass substrates offer superior thermal stability, low dielectric loss, higher I/O density, and lower warpage, making them more suitable for advanced packaging and high-frequency applications compared to traditional materials like silicon, organic, and ceramic substrates.

What are through-glass vias (TGV)?

Through-glass vias (TGV) are vertical interconnections made through a glass substrate, enabling high-density integration in 3D packaging. TGV technology enhances performance by reducing signal loss and improving thermal dissipation.

How does the low CTE of glass substrates benefit semiconductor packaging?

The low coefficient of thermal expansion (CTE) of glass substrates closely matches that of silicon, reducing thermal stress during heating and cooling cycles, thereby improving the overall reliability and performance of the semiconductor package.

What is the role of Intel’s glass core substrate?

Intel’s glass core substrate provides higher I/O density, improved thermal performance, and reduced warpage for chiplet-based packaging, enabling more efficient and scalable semiconductor solutions for high-performance computing and AI applications.

What are some key players in the glass substrate market?

Key players in the glass substrate industry include Intel, Corning, Absolics, DNP, SKC, and TSMC, which lead the development and manufacturing of high-performance glass substrates for semiconductor applications.

What challenges are faced in mass production of glass substrates?

Challenges include maintaining precision, achieving ultra-thin thicknesses without compromising performance, ensuring uniformity in through-glass via (TGV) creation, and managing the high production costs associated with advanced fine-line patterning techniques.

How do glass substrates contribute to 5G and AI technologies?