Comprehensive Analysis of FR4 Substrate Data Sheet

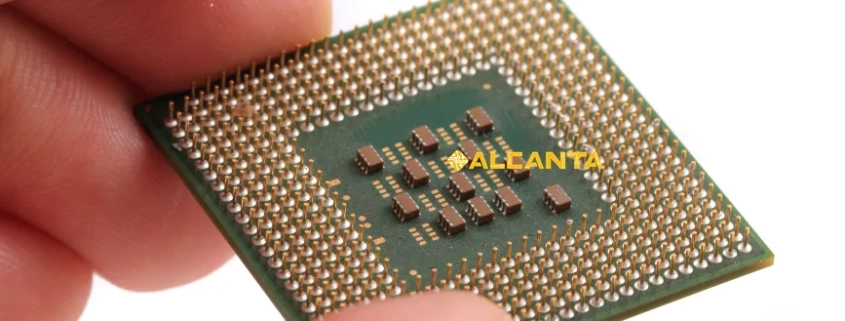

FR4, or Flame Retardant 4, refers to a type of composite material widely used as a substrate in Printed Circuit Boards (PCBs). It consists of layers of woven fiberglass cloth impregnated with epoxy resin, which gives it excellent mechanical strength, dimensional stability, and electrical insulation properties.

In PCBs, FR4 serves as the foundational material onto which copper layers are laminated to create circuitry. Its popularity stems from its affordability, availability, and versatility in various electronic applications, including consumer electronics, telecommunications equipment, and industrial machinery.

Compared to other substrate materials like ceramic or polyimide, FR4 offers a balance of performance and cost-effectiveness suitable for most general-purpose electronics. Its thermal conductivity and dimensional accuracy make it suitable for both single-layer and multi-layer PCBs, supporting complex circuit designs efficiently.

Key Properties of FR4 PCB

FR4 PCBs exhibit several crucial properties that make them ideal for electronic applications:

Electrical Properties:

FR4 substrates offer excellent electrical insulation properties, crucial for preventing short circuits and ensuring signal integrity. They have a high dielectric constant, which influences signal propagation and impedance control in high-frequency circuits.

Thermal Properties:

These PCBs have moderate thermal conductivity, which helps dissipate heat generated during operation. However, compared to materials like metal core PCBs, FR4 has lower thermal conductivity, necessitating design considerations for heat management in high-power applications.

Mechanical Properties:

FR4 is renowned for its mechanical strength and dimensional stability, crucial for maintaining the structural integrity of the PCB during manufacturing and throughout its operational life. It withstands mechanical stresses such as bending and twisting, ensuring reliability in harsh environments.

Advantages in Electronic Applications

FR4 PCBs offer several advantages that contribute to their widespread use in electronics:

– Cost-Effectiveness: FR4 is affordable and readily available, making it suitable for mass production of PCBs.

– Versatility: It supports both through-hole and surface-mount components, accommodating a wide range of circuit designs and assembly processes.

– Ease of Fabrication: FR4 substrates are compatible with standard PCB manufacturing techniques such as drilling, etching, and soldering, facilitating efficient production.

Impact on Signal Integrity and Performance

The choice of FR4 substrate significantly impacts the signal integrity and overall performance of electronic circuits:

– Signal Propagation: FR4’s dielectric properties influence signal transmission speed and attenuation, crucial for maintaining signal integrity in high-frequency applications.

– Impedance Control: Precise control of trace widths and spacing on FR4 PCBs allows designers to achieve desired impedance levels, essential for minimizing signal reflections and ensuring reliable communication.

– Noise Reduction: Proper PCB layout and grounding techniques on FR4 substrates help mitigate electromagnetic interference (EMI), enhancing the circuit’s noise immunity and overall performance.

Differences between FR4 and G10 Materials

FR4 and G10 are both types of composite materials used in PCBs, but they differ in composition and characteristics:

– Composition: FR4 is made from woven fiberglass cloth impregnated with epoxy resin, while G10 (also known as FR4-G10) uses a similar fiberglass cloth but with a higher epoxy content, resulting in a denser and more rigid material.

– Mechanical Properties: G10 is generally stronger and more rigid than standard FR4, making it suitable for applications where additional mechanical strength and rigidity are required.

– Electrical Properties: While both materials offer good electrical insulation properties, G10 typically has a lower dielectric constant and better electrical insulation performance at high frequencies compared to standard FR4.

Specific Uses and Benefits of G10 FR4 in Industry

G10 FR4 finds specific applications where its enhanced properties are advantageous:

– High-Strength Applications: G10’s superior mechanical strength makes it suitable for applications requiring robustness and resistance to mechanical stress, such as aerospace and military equipment.

– High-Frequency Applications: Due to its lower dielectric constant and better electrical properties at high frequencies, G10 FR4 is preferred in high-frequency PCB designs, such as RF (Radio Frequency) and microwave applications.

– Dimensional Stability: G10 FR4 maintains dimensional stability under varying temperature and humidity conditions, ensuring reliability in harsh environments.

– Insulation Requirements: Industries requiring stringent electrical insulation standards, such as power electronics and telecommunications, benefit from G10 FR4’s superior insulation properties.

In summary, while standard FR4 is versatile and cost-effective for general-purpose PCBs, G10 FR4 offers enhanced mechanical and electrical properties suitable for demanding applications in industries where performance and reliability are critical.

Disadvantages of FR4 Substrate

FR4 substrates, while widely used, have several limitations that need consideration in certain applications:

Thermal Limitations and Heat Dissipation Challenges

FR4 has moderate thermal conductivity compared to materials like metal core PCBs or ceramic substrates. This can lead to challenges in dissipating heat generated by high-power components or in circuits operating at elevated temperatures. Inadequate heat dissipation may affect component reliability and longevity, requiring additional thermal management techniques such as heatsinks or fans.

Mechanical Strength and Durability Concerns

While FR4 is known for its mechanical strength among standard PCB materials, it may not meet the requirements of applications with extreme mechanical stresses or harsh environmental conditions. High vibration environments or frequent mechanical shocks can potentially lead to mechanical failures such as delamination or crack propagation in FR4 PCBs.

Impact on High-Frequency Applications

FR4’s dielectric properties, including its moderate dielectric constant and loss tangent, can limit its performance in high-frequency applications. At higher frequencies, signal attenuation and loss may occur more significantly compared to substrates with lower dielectric constants, such as PTFE (Polytetrafluoroethylene) based materials. This limitation can affect the signal integrity and reliability of high-frequency circuits, necessitating careful design considerations and potentially limiting the frequency range over which FR4 can effectively operate.

In summary, while FR4 substrates offer many advantages such as affordability and ease of fabrication, these disadvantages should be carefully evaluated when designing PCBs for applications requiring stringent thermal management, high mechanical reliability, or optimal performance at high frequencies. Alternative substrate materials may be considered to address specific challenges more effectively in such cases.

Standard Height and Thickness of FR4 Substrate

FR4 substrates are available in a variety of dimensions and thicknesses to accommodate different PCB designs and manufacturing requirements:

Typical Dimensions and Variations in FR4 Thickness

FR4 thicknesses typically range from 0.2 mm (8 mil) to 3.2 mm (125 mil), with standard increments such as 0.4 mm, 0.6 mm, 1.0 mm, 1.6 mm, and 2.0 mm being commonly used. The choice of thickness depends on the specific application requirements, including mechanical strength, impedance control, and thermal management. Thicker substrates provide more rigidity and better heat dissipation, while thinner substrates are lighter and may be preferred for compact designs.

Industry Standards and Variations in Manufacturing

The manufacturing of FR4 substrates adheres to various industry standards and specifications, ensuring consistency and reliability in PCB production. Standards such as IPC-4101 define the base materials for rigid and multilayer printed boards, including FR4, and specify characteristics such as dielectric constant, glass transition temperature (Tg), and dimensional stability. Manufacturers may also offer variations in FR4 materials tailored to specific applications, such as high-Tg FR4 for applications requiring enhanced thermal performance or halogen-free FR4 for environmental considerations.

Understanding these dimensions and standards is crucial for PCB designers to select the appropriate FR4 substrate that meets their design requirements and ensures reliable performance in electronic applications.

Frequency Performance of FR4 Substrate

FR4 substrates exhibit distinct characteristics that influence their performance across different frequency ranges:

Frequency Range Suitability for FR4 Substrate

FR4 is suitable for a wide range of frequencies commonly used in electronic circuits, typically up to several gigahertz (GHz). It is well-suited for applications in consumer electronics, telecommunications, and general-purpose PCBs where frequencies range from low to moderate levels. However, as frequencies increase, the electrical properties of FR4, such as its dielectric constant and loss tangent, can impact signal integrity and performance.

Effects of Frequency on Signal Propagation and Attenuation

At higher frequencies, the dielectric properties of FR4 become more critical. The dielectric constant affects the velocity of signal propagation through the substrate, influencing signal timing and phase shift in high-speed digital and RF circuits. Additionally, the loss tangent determines the amount of signal attenuation as it travels through the PCB traces and layers.

– Signal Propagation: FR4 substrates exhibit moderate dielectric constants, typically ranging from 4.0 to 4.8, which affects the velocity of signal propagation. This property is crucial for maintaining signal integrity and ensuring accurate timing in digital circuits.

– Signal Attenuation: As frequency increases, the signal attenuation in FR4 also increases due to its dielectric losses. This can result in reduced signal strength and increased noise, impacting the overall performance of high-frequency circuits. Designers must consider trace impedance matching and signal routing techniques to minimize these effects.

Understanding the frequency performance characteristics of FR4 substrates allows PCB designers to optimize their designs for specific frequency ranges, ensuring reliable operation and minimizing signal degradation in electronic systems. For applications requiring higher frequencies or stringent performance criteria, alternative substrate materials with lower dielectric constants and improved high-frequency properties may be considered.

FAQs about fr4 substrate datasheet

FR4 substrate material is a type of fiberglass-reinforced epoxy laminate that is commonly used in the manufacture of printed circuit boards (PCBs).

Disadvantages of FR4 substrate include relatively high moisture absorption, limited thermal conductivity compared to other substrates like ceramic, and susceptibility to delamination under extreme conditions.

The standard height (thickness) of FR4 substrate for PCBs typically ranges from 0.4 mm to 3.2 mm, depending on the specific application and design requirements.

FR4 substrate does not have a specific frequency range inherently associated with it. Its electrical performance, including frequency characteristics, depends on the PCB design, layout, and specific parameters such as trace dimensions and layer stack-up.