Key Differences Between FR4 Rogers Double Sided PCB Materials

Printed Circuit Boards (PCBs) are essential components in modern electronics, providing the physical foundation for connecting and supporting electronic components. They serve as the backbone for everything from consumer gadgets to advanced industrial devices. The design and material of a PCB greatly influence its performance, reliability, and cost. Among the most commonly used materials for PCB manufacturing are FR4 and Rogers, each offering distinct advantages for different applications. FR4 is a widely used material known for its durability and affordability, while Rogers is recognized for its superior electrical performance, especially in high-frequency circuits. In this blog, we will compare FR4 Rogers double sided PCB solutions, exploring the differences in material properties, performance characteristics, and suitable applications. Our aim is to help you understand which material is best suited for your specific needs, whether you’re designing consumer electronics or high-performance communication systems.

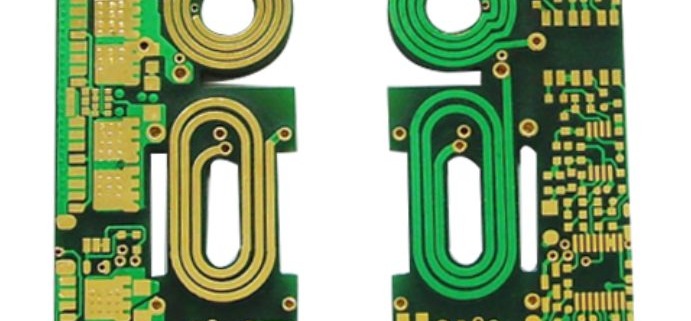

Understanding FR4 Rogers Double Sided PCB

When it comes to designing and manufacturing Printed Circuit Boards (PCBs), the material used plays a crucial role in determining the performance and durability of the final product. Two of the most commonly used materials for FR4 Rogers double sided PCB designs are FR4 and Rogers. Each has unique characteristics, making them suitable for different applications. Let’s take a closer look at both.

What is FR4 in the Context of FR4 Rogers Double Sided PCB?

FR4 (Flame Retardant 4) is one of the most widely used materials in PCB manufacturing. It is a type of fiberglass-reinforced epoxy laminate, which means it consists of a fiberglass base material bonded with an epoxy resin. The “Flame Retardant” designation indicates that the material is treated to resist burning, making it safe for use in electronics. FR4 is well-known for its versatility and relatively low cost, making it an ideal choice for a broad range of consumer electronics and general-purpose applications.

Common applications of FR4 include:

- Consumer Electronics: Smartphones, tablets, and personal computers.

- Computers and Networking: Laptops, desktop PCs, and networking equipment like routers and switches.

- Telecommunications: Base stations, transceivers, and other communication devices.

Although FR4 Rogers double sided PCB can be used in various electronics, FR4 tends to have limitations in high-frequency applications due to higher signal loss and lower thermal stability compared to advanced materials like Rogers.

What is Rogers PCB and How It Relates to FR4 Rogers Double Sided PCB?

Rogers PCBs are made using advanced materials developed by Rogers Corporation, which are specially designed for high-performance applications. These materials are engineered to offer superior electrical characteristics, including low loss, high-frequency performance, and excellent thermal stability. Unlike FR4, Rogers PCBs are typically used for more specialized and demanding applications, such as RF (Radio Frequency) and microwave circuits.

Rogers PCBs are often made from materials like RT Duroid, Rogers 4000 series, and Rogers 5880. These materials provide low dielectric loss, high-speed signal integrity, and exceptional performance at high frequencies. They are particularly useful in applications where signal quality is critical and where high-speed, low-loss transmission is required.

Special characteristics of Rogers PCBs include:

- Low Loss: Rogers materials are known for their minimal signal loss, making them ideal for high-frequency and high-speed applications.

- High-Frequency Performance: Rogers PCBs are capable of maintaining stable electrical properties at frequencies beyond the capabilities of FR4.

- High Temperature Stability: They are designed to perform well even in high-temperature environments, making them suitable for advanced telecommunications, aerospace, and military applications.

While FR4 Rogers double sided PCB can be used for various electronic products, Rogers offers significantly higher performance for high-frequency, low-loss applications, making it the preferred choice for cutting-edge technologies where signal integrity and thermal stability are paramount.

Key Differences Between FR4 Rogers Double Sided PCB Materials

When choosing between FR4 Rogers double sided PCB options, it is essential to understand the key differences in material composition, electrical performance, thermal stability, cost, and mechanical properties. Each of these factors plays a crucial role in determining which material is best suited for your specific application. Below, we will compare FR4 and Rogers in more detail to help clarify these distinctions.

Material Composition

FR4 is a glass fiber epoxy composite, which is made by bonding layers of woven glass fiber with an epoxy resin. This material is widely available, cost-effective, and easy to manufacture, making it a popular choice for general-purpose applications in a variety of industries. The composition of FR4 provides a good balance of electrical, mechanical, and thermal properties, making it versatile for everyday electronics.

Rogers, on the other hand, uses advanced materials such as PTFE (polytetrafluoroethylene), ceramic-filled composites, and other high-performance substances. These materials are engineered to offer superior electrical performance, low signal loss, and enhanced thermal stability. The composition of Rogers materials allows for better high-frequency signal handling, lower dielectric loss, and more precise manufacturing, making it ideal for applications that require high-performance and precision, such as telecommunications, aerospace, and military devices.

Electrical Performance

One of the biggest differences between FR4 Rogers double sided PCB options lies in their electrical performance, especially at high frequencies.

- FR4: While FR4 performs well for standard applications, its signal loss increases at higher frequencies. This is due to the relatively high dielectric loss of the material, which becomes more pronounced in circuits that operate at GHz frequencies. As a result, FR4 is better suited for low-to-medium frequency applications such as consumer electronics and standard digital circuits.

- Rogers: Rogers PCBs excel in high-frequency applications due to their superior electrical properties. With low signal loss, high dielectric constant stability, and minimal interference, Rogers materials are ideal for high-speed and RF (radio frequency) applications. They maintain signal integrity even at high frequencies, making them the go-to choice for demanding applications such as 5G communications, satellite systems, and radar equipment.

Thermal Performance

FR4 can tolerate moderate temperatures, making it suitable for many electronics and consumer devices. Its glass transition temperature (Tg) typically ranges around 130°C, meaning it can withstand temperatures up to that point before the material begins to soften and lose its rigidity. However, FR4 is not designed for high-heat environments and may not perform well under extreme thermal stress.

Rogers, however, is specifically designed to handle higher thermal stresses. Many Rogers materials feature a higher Tg (often over 200°C) and superior thermal conductivity, allowing them to remain stable under higher temperatures. This makes Rogers ideal for high-performance applications where heat dissipation is critical, such as in high-frequency microwave circuits, automotive electronics, and industrial equipment that operates in harsh environments.

Cost

FR4 is significantly more cost-effective than Rogers. As a widely used material with standard properties, FR4 is mass-produced and readily available, making it an affordable option for a variety of general-purpose applications. The cost-effectiveness of FR4 makes it the material of choice for consumer electronics, computers, and other low-to-mid-range products.

Rogers, however, is much more expensive due to the advanced materials used in its production. The higher cost is justified by its exceptional electrical performance, higher thermal stability, and suitability for high-frequency applications. As such, Rogers is generally used in specialized, high-performance applications such as radar, satellite communications, and other RF-sensitive systems where cost is less of a concern.

Mechanical Properties

In terms of mechanical properties, FR4 offers a good balance of stiffness and durability. It is robust enough for most consumer electronics and general-purpose circuits, providing the necessary mechanical strength to support components and resist environmental wear. However, it has a relatively high coefficient of thermal expansion (CTE), meaning that it can expand and contract with temperature fluctuations, which may affect performance over time in some designs.

Rogers materials, on the other hand, are engineered with enhanced mechanical properties, including a lower coefficient of thermal expansion (CTE). This makes Rogers more suitable for high-precision applications where stability and minimal expansion or contraction are critical. In environments where mechanical precision is crucial—such as in high-frequency radar or aerospace systems—Rogers materials ensure better reliability and performance.

FR4 Rogers double sided PCB solutions differ significantly in terms of material composition, electrical performance, thermal stability, cost, and mechanical properties. While FR4 is affordable and effective for standard electronics, Rogers offers higher performance for specialized applications that demand low signal loss, high-frequency capabilities, and superior thermal and mechanical stability. The choice between FR4 and Rogers largely depends on the specific needs of your project—whether you prioritize cost-effectiveness or require the high-performance capabilities of Rogers.

Comparison of FR4 and Rogers in FR4 Rogers Double Sided PCB Designs

When selecting a material for a FR4 Rogers double sided PCB, it’s important to evaluate not only the material properties but also the design flexibility, reliability, and performance characteristics that each material offers. Although both FR4 Rogers double sided PCB designs can support a wide range of applications, there are key differences in how each material performs, especially when it comes to high-frequency circuits and demanding environments.

Design Flexibility

Both FR4 and Rogers materials can be used for double-sided PCBs, but the design flexibility they offer varies significantly, especially when considering high-density and high-performance circuits.

- FR4: The use of FR4 in double-sided PCBs is common for standard electronic products. It allows for a reasonable amount of design flexibility and supports various layouts, from basic consumer devices to moderately complex electronics. However, FR4’s limitations in high-frequency performance and its dielectric properties restrict its ability to handle very high-density designs. As the complexity and frequency requirements of a design increase, FR4 may not offer the best performance.

- Rogers: In contrast, Rogers double sided PCBs are designed to support much higher-density layouts, particularly for specialized high-frequency applications. The advanced materials used in Rogers, such as PTFE and ceramic-filled compounds, allow for better signal integrity and lower loss at high frequencies. This makes Rogers ideal for designs that require smaller, high-performance components packed tightly together, such as in RF (radio frequency) systems, telecommunications, and aerospace technologies. Rogers’ materials are also more suited to maintaining performance in smaller, more compact designs that operate in specialized environments.

Reliability

The reliability of FR4 Rogers double sided PCB depends on the type of environment and the operating conditions.

- FR4: FR4 offers good reliability for standard applications, making it the go-to choice for consumer electronics, household appliances, and general-purpose circuit boards. It is durable enough for everyday use and can withstand moderate temperatures and environmental conditions. However, in high-speed or high-frequency environments, FR4’s reliability diminishes. Its higher signal loss and lower thermal stability make it unsuitable for environments with high temperatures or critical performance demands. As signal degradation increases, the reliability of FR4 starts to drop in applications that require precise signal transmission, such as telecommunications and high-speed networking.

- Rogers: Rogers materials offer much greater reliability in harsher environments. Their superior thermal stability, lower signal loss, and resistance to environmental degradation make them ideal for high-performance applications. Whether operating in extreme temperatures, under high-frequency conditions, or in harsh environments (such as aerospace or military electronics), Rogers double sided PCBs maintain their mechanical integrity and electrical performance. The lower dielectric loss of Rogers materials ensures that signal transmission remains stable, which is critical for applications in telecommunications, radar systems, and medical equipment.

Performance at High-Frequency

One of the most significant advantages of Rogers double sided PCBs over FR4 is their performance at high frequencies.

- FR4: When used in high-frequency circuits, FR4 experiences significant signal degradation. The dielectric constant of FR4 varies with frequency, leading to greater signal loss and less efficient transmission at higher speeds. As the frequency increases, the PCB’s performance deteriorates, limiting FR4’s effectiveness in RF or microwave applications. This is why FR4 is best suited for low-to-medium frequency applications where signal loss is not a significant concern. For circuits running at frequencies higher than 1 GHz, FR4 is generally not recommended unless its performance can be compensated for with additional circuit design techniques.

- Rogers: Rogers double sided PCB designs excel in high-frequency applications. The materials used in Rogers, like Rogers 5880 and RT Duroid, provide a stable dielectric constant even at very high frequencies, making them ideal for RF (radio frequency) and microwave applications. They have a lower dielectric loss, meaning less signal degradation over long distances or high-frequency transmissions. The ability of Rogers materials to maintain signal quality at frequencies of several GHz or even higher makes them perfect for use in wireless communication, radar, satellite systems, and other applications requiring high-speed signal transmission with minimal interference or loss.

While both FR4 Rogers double sided PCB solutions can serve in double-sided configurations, Rogers clearly outperforms FR4 when it comes to design flexibility for high-frequency circuits, reliability in extreme environments, and overall performance at high speeds. FR4 remains an excellent choice for more general applications, where cost-effectiveness and ease of use are key. However, for specialized, high-performance, and high-frequency designs, Rogers double sided PCBs provide the superior choice, offering stability, reliability, and unmatched electrical performance under demanding conditions.

Disadvantages of FR4 in FR4 Rogers Double Sided PCB

While FR4 Rogers double sided PCB solutions are widely used for many standard applications due to their cost-effectiveness and reliability, FR4 has several notable disadvantages that may limit its performance in more demanding environments. These limitations primarily arise when higher frequencies, extreme temperatures, or more complex circuit designs are involved. Let’s explore the specific drawbacks of using FR4 in double-sided PCB designs.

Limited High-Frequency Performance

One of the most significant disadvantages of FR4 Rogers double sided PCB designs is FR4’s limited performance at high frequencies. As the frequency of the signal increases, FR4 experiences greater signal loss and higher dielectric losses. At frequencies beyond a few GHz, FR4 becomes increasingly unsuitable for high-performance applications, such as RF (radio frequency) or microwave circuits.

This limitation occurs because the dielectric constant of FR4 fluctuates with frequency, leading to signal degradation and reduced efficiency. For designs that require high-speed data transmission or precise signal integrity, FR4 is not ideal. It is commonly used in low-to-medium frequency applications, but when higher-frequency performance is necessary, alternatives like Rogers double sided PCBs are preferred for their superior electrical properties, such as low signal loss and minimal distortion at high frequencies.

Lower Thermal Stability

FR4 also has lower thermal stability compared to Rogers. While it is designed to handle moderate temperatures, its glass transition temperature (Tg) is typically around 130°C, which means it can start to lose its structural integrity and mechanical properties at temperatures above this threshold. This limits FR4’s ability to perform in high-temperature environments or in designs where heat dissipation is critical.

Rogers materials are engineered to withstand higher thermal stresses and can handle temperatures well above 130°C. This makes Rogers double sided PCBs far more reliable in high-heat environments, such as in aerospace, military, or high-performance electronic applications. For projects that require consistent operation in extreme temperatures, FR4 may not be the best material choice.

Lower Electrical Performance

For complex or specialized applications that demand low-loss or high-speed performance, FR4 falls short in delivering the required electrical properties. The dielectric constant of FR4 is relatively high and inconsistent across frequencies, which results in signal degradation, especially in high-speed and high-frequency circuits.

In high-frequency applications, such as telecommunications or advanced networking, the electrical performance of FR4 is not sufficient to maintain signal integrity over long distances or at higher speeds. The material’s high dielectric loss leads to increased signal attenuation, making it unsuitable for circuits requiring precise and stable signal transmission, such as those found in radar, satellite systems, or high-speed digital designs. For these applications, Rogers provides superior low-loss performance, ensuring the integrity of high-frequency signals.

Not Suitable for Miniaturized Designs

As the demand for miniaturized electronic devices increases, FR4 may struggle to meet the needs of high-density circuits that are common in modern designs. While FR4 Rogers double sided PCB solutions can be manufactured to meet many circuit requirements, FR4 lacks the precise manufacturing capabilities needed for the ultra-small, high-density designs often required in next-generation electronics.

Miniaturized designs demand more compact, precise layouts with minimal signal loss and high-speed operation. The material properties of FR4 limit the density of components that can be placed on a PCB without sacrificing electrical performance. Rogers materials, with their better high-frequency performance and low-loss characteristics, are more suited for these smaller, more complex designs, particularly in fields like telecommunications, medical devices, and high-performance computing.

While FR4 Rogers double sided PCB materials are widely used for general-purpose, low-cost applications, FR4 has several key disadvantages that may limit its effectiveness in more advanced, high-performance designs. Its limited high-frequency performance, lower thermal stability, and lower electrical performance make it unsuitable for complex, high-speed, or high-temperature environments. Additionally, as electronic designs continue to become more miniaturized, FR4 may struggle to meet the growing demands for high-density, high-performance circuit boards. For projects that require superior thermal stability, low-loss performance, or precise, high-frequency signal handling, Rogers materials are the preferred choice.

Use Cases of FR4 Rogers Double Sided PCB

Choosing between FR4 Rogers double sided PCB solutions depends largely on the specific requirements of your project. The material you select will influence the performance, reliability, and cost of your final design. In this section, we’ll discuss when to choose FR4 and when to opt for Rogers, focusing on their ideal use cases based on performance needs and application environments.

When to Choose FR4

FR4 is an excellent choice for a wide range of standard, cost-effective applications. Its affordability and versatility make it ideal for projects that don’t require high-frequency performance, precision, or high thermal stability. Here are the most common use cases for FR4 Rogers double sided PCB designs when FR4 is the preferred material:

- Cost-Effective Designs: For projects where cost is a significant concern, FR4 offers a budget-friendly solution. Because it is widely available and relatively inexpensive to manufacture, FR4 is the material of choice for mass-produced consumer electronics and basic electronic components. When keeping production costs low is a top priority without compromising on basic functionality, FR4 is a reliable option.

- Standard Consumer Electronics: FR4 is commonly used in the manufacturing of everyday consumer products like smartphones, laptops, tablets, televisions, and home appliances. These devices typically operate at low-to-medium frequencies and don’t require the high-performance capabilities of materials like Rogers. As long as the product doesn’t demand high-speed, high-frequency signal transmission, FR4 can meet the needs of these applications effectively.

- Low-Frequency Applications: FR4 is suitable for electronic circuits that operate at lower frequencies, where signal degradation and loss are less of an issue. Examples include simple digital circuits, low-power devices, and standard communication systems that operate in the audio or video range. For these types of systems, the relatively higher dielectric loss of FR4 has little impact on performance, making it an ideal material for the job.

- General-Purpose Circuit Boards: When designing general-purpose PCBs for non-specialized applications, FR4 offers a reliable and readily available solution. It’s often used in prototyping, testing, and development of various devices across industries such as automotive, industrial controls, and medical electronics (for non-critical applications). FR4’s durability and availability make it a go-to material for these purposes.

When to Choose Rogers

Rogers materials are specifically engineered for high-performance, high-precision applications that require superior electrical, thermal, and mechanical properties. Here are the key scenarios when Rogers double sided PCBs are the better choice:

- High-Frequency Applications (RF, Microwave, Telecommunications): Rogers is the ideal choice for high-frequency applications such as RF (radio frequency), microwave circuits, and telecommunications. Its low dielectric loss, stable dielectric constant, and superior high-frequency performance make it perfect for RF and microwave systems used in wireless communication, satellite systems, and radar. For designs that involve signal transmission at frequencies higher than 1 GHz, Rogers provides the necessary signal integrity to maintain performance and avoid degradation.

- High-Precision, High-Performance Circuits: Applications such as radar systems, satellite communications, aerospace, and military electronics often require extremely precise, high-performance circuit boards. These systems demand minimal signal loss and the ability to perform under high-frequency and high-thermal conditions. Rogers double sided PCBs are designed to meet these exact needs, providing the reliability and performance necessary for these critical applications. Whether it’s for radar signal processing or satellite communication systems, Rogers’ materials ensure that the high-speed and low-loss signals are transmitted without distortion.

- Environments That Require High Thermal Stability and Low Signal Loss: Certain applications, such as those used in automotive, industrial, or high-temperature environments, require PCBs that can withstand high heat and maintain signal integrity. Rogers double sided PCB designs excel in these conditions due to their higher glass transition temperature (Tg) and superior thermal conductivity. Whether it’s a high-power RF amplifier or a high-temperature industrial sensor, Rogers provides the thermal stability and low signal loss required to ensure long-term reliability in extreme conditions.

FR4 Rogers double sided PCB solutions each have their place depending on the specific demands of your application:

- Choose FR4 for cost-effective designs, standard consumer electronics, low-frequency applications, and general-purpose circuit boards. It is an affordable, reliable solution for less demanding applications where high-frequency performance and thermal stability are not critical.

- Choose Rogers when you need to handle high-frequency applications, such as RF, microwave, and telecommunications. It is also the best choice for high-precision circuits in demanding environments that require low signal loss, high thermal stability, and reliable performance at high frequencies. For advanced systems like radar, satellite communications, and high-performance telecommunications, Rogers double sided PCBs deliver the necessary capabilities.

The decision between FR4 Rogers double sided PCB materials will depend on the specific needs of your project, including performance, cost considerations, and environmental factors.

FQAs Abut FR4 Rogers Double Sided PCB

What is the difference between Rogers and FR4 PCB?

- Material Composition: FR4 is made from glass fiber and epoxy resin, whereas Rogers PCBs are made from advanced materials like PTFE (polytetrafluoroethylene) or ceramic-filled composites.

- Electrical Performance: Rogers PCBs offer superior electrical properties, especially at high frequencies, with low signal loss and higher stability. FR4 has higher signal loss and is less effective at high frequencies.

- Thermal Performance: Rogers PCBs have better thermal stability, with a higher glass transition temperature (Tg), making them ideal for high-temperature applications. FR4 has a lower Tg and is less suited for high-thermal environments.

- Cost: FR4 is much more cost-effective compared to Rogers, making it suitable for general-purpose and low-cost applications. Rogers is more expensive due to its superior performance in high-frequency and high-temperature environments.

What is the difference between FR2 and FR4 PCB?

- Material Composition: FR2 is made from paper and phenolic resin, which makes it a less durable material compared to FR4, which uses fiberglass and epoxy resin for a stronger, more durable build.

- Electrical Performance: FR4 provides better electrical performance, especially at higher frequencies, compared to FR2, which has higher signal loss and lower stability at higher frequencies.

- Thermal Performance: FR2 has lower thermal resistance, making it less suited for high-temperature environments, while FR4 can tolerate higher temperatures and is more thermally stable.

- Applications: FR2 is typically used for low-frequency applications and in simpler electronics, while FR4 is more versatile, used for a wide range of applications, including consumer electronics, computers, and telecommunication systems.

What is the difference between FR4 and RT Duroid?

- Material Composition: FR4 is a fiberglass-reinforced epoxy laminate, while RT Duroid is a high-performance material made from PTFE (polytetrafluoroethylene) combined with fillers like ceramic for enhanced electrical properties.

- Electrical Performance: RT Duroid provides superior electrical performance, especially at high frequencies, with lower signal loss and higher stability compared to FR4. FR4 has higher dielectric loss and is not suitable for high-frequency applications.

- Thermal Performance: RT Duroid offers excellent thermal stability, even at high temperatures, whereas FR4 has lower thermal performance and cannot withstand as high temperatures.

- Applications: RT Duroid is typically used in high-frequency, high-performance applications such as RF (radio frequency) circuits, satellite communications, and aerospace, while FR4 is used for general-purpose applications, especially where cost is a factor.

What are the disadvantages of FR4?

- Limited High-Frequency Performance: FR4 has significant signal loss at higher frequencies, making it unsuitable for high-speed or high-frequency circuits, such as those used in RF, microwave, and telecommunications applications.

- Lower Thermal Stability: FR4 has a relatively low glass transition temperature (Tg), typically around 130°C, which makes it less suited for high-temperature environments.

- Lower Electrical Performance: FR4 is not ideal for applications requiring high-speed signal transmission or low-loss performance, as its dielectric constant can fluctuate and cause signal degradation at higher frequencies.

- Not Ideal for Miniaturized Designs: As electronic components become more miniaturized, FR4 may not meet the performance requirements for high-density, precision circuits needed in modern electronics, particularly in fields like telecommunications, medical devices, and high-performance computing.