FR4 PCB Material: Properties and Advantages Explained

FR4, standing for Flame Retardant 4, is a widely used material in the manufacturing of printed circuit boards (PCBs). Its versatility, durability, and excellent electrical properties make it indispensable in modern electronics. FR4 consists of layers of fiberglass cloth impregnated with epoxy resin, offering both mechanical strength and electrical insulation. PCBs made from FR4 exhibit high thermal stability, allowing them to withstand the rigors of various electronic applications. Understanding the properties and specifications of FR4 is crucial for engineers and designers aiming to optimize the performance and reliability of their electronic devices. In this exploration, we delve into the composition, properties, applications, and significance of FR4 PCB material, shedding light on its pivotal role in the electronics industry.

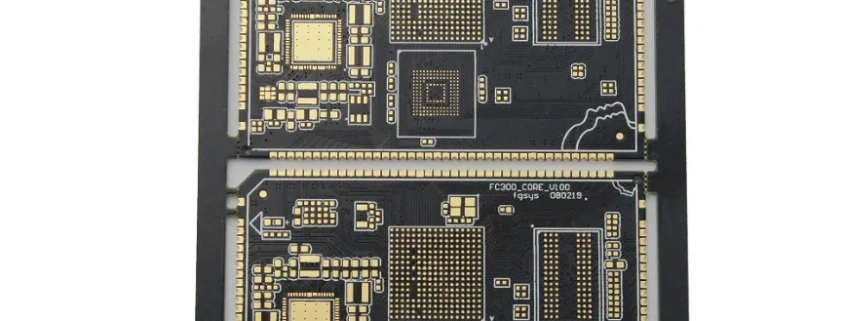

What is FR4 PCB Material?

FR4 PCB material, also known as Flame Retardant 4 PCB material, is a type of substrate commonly used in the fabrication of printed circuit boards (PCBs).

Unveiling the Full Name and Basic Definition of FR4: FR4 derives its name from its key properties: “Flame Retardant” and the number “4,” indicating its classification in the flame retardancy standard. It is composed of layers of fiberglass cloth bonded together by epoxy resin, forming a sturdy and heat-resistant substrate for PCBs.

Exploring the Significance of FR4 in PCB Manufacturing: FR4’s significance in PCB manufacturing stems from its exceptional combination of properties. It offers excellent electrical insulation, mechanical strength, and thermal stability, making it ideal for various electronic applications. Its flame-retardant nature ensures safety in case of fire, a critical factor in electronics. Moreover, FR4’s compatibility with standard PCB fabrication processes, such as etching and soldering, simplifies manufacturing while maintaining high performance. As a result, FR4 has become the go-to choice for PCB substrates, playing a vital role in the production of reliable and high-performance electronic devices.

Composition of FR4 PCB Material

FR4 PCB material is composed of several key components, each contributing to its unique properties and performance characteristics.

Analyzing the Specific Components of FR4 Material

- Fiberglass Cloth: The primary structural component of FR4, fiberglass cloth consists of thin strands of glass woven together to form a strong and resilient substrate. This provides mechanical strength and dimensional stability to the PCB.

- Epoxy Resin: Epoxy resin serves as the binding agent in FR4 material, holding the fiberglass layers together. It provides adhesion, insulation, and moisture resistance, enhancing the overall durability and reliability of the PCB.

- Fillers and Additives: Various fillers and additives may be incorporated into the epoxy resin to further enhance specific properties of the FR4 material, such as flame retardancy, thermal conductivity, or impedance control.

Explaining the Impact of These Components on PCB Performance

- Mechanical Strength: The fiberglass cloth, reinforced by the epoxy resin, imparts high mechanical strength to the FR4 PCB material, enabling it to withstand physical stresses during handling, assembly, and operation.

- Electrical Insulation: The combination of fiberglass and epoxy resin provides excellent electrical insulation properties, preventing leakage currents and ensuring signal integrity in the PCB.

- Thermal Stability: The heat-resistant nature of fiberglass and epoxy resin allows FR4 PCBs to maintain dimensional stability and electrical performance over a wide temperature range, crucial for applications in harsh environments or high-power electronics.

- Flame Retardancy: The inclusion of flame-retardant additives in the FR4 material enhances its fire resistance, minimizing the risk of PCB damage or combustion in case of a fire event.

Understanding the composition of FR4 PCB material and its influence on performance is essential for designing and manufacturing reliable and high-quality printed circuit boards for various electronic applications.

Properties and Specifications of FR4 PCB Material

FR4 PCB material exhibits a range of properties and specifications that make it well-suited for diverse electronic applications.

Showcasing Key Properties of FR4 PCB Material

- Density: The density of FR4 PCB material typically ranges from 1.7 to 1.9 grams per cubic centimeter (g/cm³), providing a balance between mechanical strength and weight.

- Thickness: FR4 PCB material is available in various thicknesses, commonly ranging from 0.4 to 3.2 millimeters (mm), catering to different design requirements and applications.

- Dielectric Constant: The dielectric constant of FR4 PCB material is typically around 4.2 to 4.8, depending on factors such as resin content and fiberglass weave. This property influences signal propagation and impedance characteristics in the PCB.

- Thermal Conductivity: FR4 PCB material exhibits moderate thermal conductivity, typically in the range of 0.3 to 0.5 watts per meter-kelvin (W/m·K), facilitating heat dissipation from electronic components mounted on the board.

- Flame Retardancy: FR4 PCB material meets stringent flame retardancy standards, such as UL 94V-0, ensuring safety and reliability in electronic devices.

Providing Common Specifications and Technical Specifications of FR4 PCB Material

- Standard Sizes: FR4 PCB material is available in standard sheet sizes, such as 18″ x 24″ (457 mm x 610 mm) or 24″ x 36″ (610 mm x 914 mm), with custom sizes also offered by manufacturers.

- Copper Clad Thickness: FR4 PCB material is often supplied with copper cladding on one or both sides, with common copper thicknesses ranging from 1 ounce (35 micrometers) to 3 ounces (105 micrometers) per square foot.

- Surface Finish: Common surface finishes for FR4 PCB material include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservatives), catering to different assembly and soldering requirements.

- Electrical Performance: FR4 PCB material typically exhibits excellent electrical performance, with low dissipation factor, high insulation resistance, and consistent dielectric properties across a wide frequency range.

Understanding these properties and specifications of FR4 PCB material is essential for selecting the right material for specific design requirements and ensuring the performance and reliability of electronic devices.

Advantages and Applications of FR4 PCB Material

FR4 PCB material holds a prominent position in the realm of PCB manufacturing due to its array of advantages and versatile applications.

Explaining Why FR4 is the Preferred Material in PCB Manufacturing

- Superior Electrical Properties: FR4 offers excellent electrical insulation and high dielectric strength, ensuring reliable signal transmission and minimizing signal loss or interference.

- Heat Resistance: FR4 PCB material exhibits remarkable thermal stability, allowing it to withstand elevated temperatures during soldering and operation without compromising performance.

- Mechanical Strength: The combination of fiberglass reinforcement and epoxy resin lends FR4 PCBs high mechanical strength and rigidity, enhancing durability and resistance to mechanical stresses.

- Cost-Effectiveness: FR4 PCB material is relatively cost-effective compared to alternative materials, making it an attractive choice for mass production and cost-sensitive applications.

- Ease of Fabrication: FR4 is compatible with standard PCB fabrication processes, including drilling, etching, and soldering, simplifying manufacturing and reducing production time and costs.

Exploring the Widespread Applications of FR4 in Various Electronic Devices

- Communication Equipment: FR4 PCBs are extensively used in communication devices such as routers, switches, modems, and antennas due to their high-frequency performance and reliability.

- Computer Hardware: FR4 PCB material is ubiquitous in computer hardware components, including motherboards, graphic cards, memory modules, and central processing units (CPUs), where it provides stable electrical connections and robust support.

- Consumer Electronics: FR4 PCBs find applications in a wide range of consumer electronics, including smartphones, tablets, televisions, and gaming consoles, owing to their combination of performance, durability, and cost-effectiveness.

- Industrial Electronics: In industrial settings, FR4 PCBs are employed in control systems, instrumentation, power supplies, and automation equipment, where they offer resilience to harsh environments and demanding operating conditions.

- Medical Devices: FR4 PCB material is utilized in medical devices such as diagnostic equipment, patient monitors, and medical imaging systems, where reliability and precision are paramount for patient safety and healthcare outcomes.

Overall, the superior electrical properties, heat resistance, and mechanical strength of FR4 PCB material make it indispensable across a wide spectrum of electronic devices, contributing to the advancement of technology in various industries.

Price and Availability of FR4 PCB Material

FR4 PCB material offers a balance of performance and affordability, making it widely available in the market. Here’s a closer look at its price range, market availability, and considerations for purchasing:

Analyzing the Price Range and Market Availability of FR4 PCB Material

- Price Range: The price of FR4 PCB material can vary based on factors such as thickness, copper cladding, surface finish, and quantity ordered. Generally, the price ranges from a few dollars per square foot for standard FR4 material to higher costs for specialized variants or custom specifications.

- Market Availability: FR4 PCB material is readily available from numerous suppliers and distributors worldwide. It is commonly stocked by electronic component distributors, PCB manufacturers, and online marketplaces, ensuring easy accessibility for buyers.

Providing Avenues for Purchasing FR4 PCB Material and Considerations for Buyers

- Direct Suppliers and Manufacturers: Buyers can purchase FR4 PCB material directly from manufacturers or authorized distributors. This ensures access to genuine products and technical support.

- Electronic Component Distributors: Many electronic component distributors carry FR4 PCB material in their inventory. Buyers can explore catalogs and websites of reputable distributors to compare prices and specifications.

- Online Marketplaces: Online platforms offer a wide selection of FR4 PCB material from various sellers worldwide. However, buyers should exercise caution and verify the credibility of sellers to avoid counterfeit or substandard products.

- Considerations for Buyers: When purchasing FR4 PCB material, buyers should consider factors such as quality, lead time, minimum order quantity, shipping costs, and technical support. It’s essential to choose a supplier that meets the specific requirements and standards of the project while offering competitive pricing and reliable service.

By carefully assessing price, quality, and supplier reputation, buyers can procure high-quality FR4 PCB material that meets their project needs within budget and schedule constraints.

Contact Us NOW

FAQs About FR4 PCB Material

FR4 is used in PCBs due to its superior electrical properties, heat resistance, mechanical strength, and cost-effectiveness.

FR4 stands for Flame Retardant 4, indicating its flame retardancy classification and the number “4” representing its level of flame resistance.

The composition of FR4 material typically includes layers of fiberglass cloth bonded together by epoxy resin, with additional additives for specific properties.

FR4 PCB material comes in various thicknesses, commonly ranging from 0.4 to 3.2 millimeters (mm), depending on design requirements and applications.