Advantages of Using FPC Flexible PCB in Modern Electronics

A Printed Circuit Board (PCB) is the foundation of most electronic devices, providing mechanical support and electrical connections for electronic components. As technology evolves toward miniaturization and portability, the demand for more adaptable circuit solutions has led to the development of fpc flexible pcb technology. Unlike traditional rigid and inflexible boards, flexible printed circuits offer a bendable, lightweight alternative that can conform to complex shapes and dynamic movements. This flexibility makes them ideal for compact devices like smartphones, wearables, medical implants, and automotive sensors. The evolution of flexible circuit technology marks a major step in modern electronics, allowing for increased design freedom, improved reliability, and space efficiency. With electronics becoming more integrated into daily life and industrial systems, the importance of these flexible solutions continues to grow, replacing rigid boards in many critical applications where space-saving and flexibility are essential.

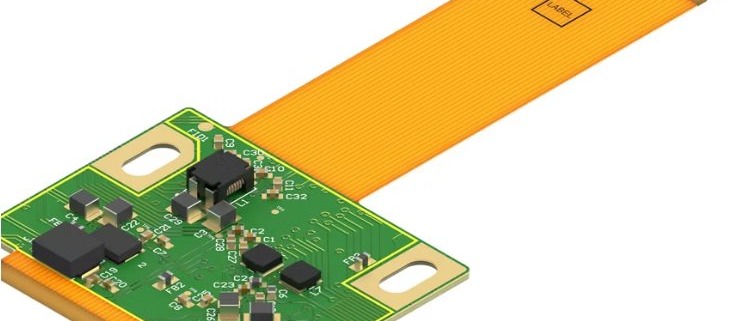

What Is an FPC Flexible PCB?

An fpc flexible pcb (Flexible Printed Circuit) is a PCB designed to bend, twist, and fold, fitting compact or irregular electronic assemblies. “FPC” highlights its key trait—flexibility—built on traditional PCB principles.

The basic structure of an fpc flexible pcb consists of several key layers. The substrate is typically made from polyimide (PI), known for its excellent thermal and mechanical properties. On top of the substrate lies a thin copper foil, which forms the conductive traces. An adhesive layer bonds these materials together, and a coverlay—a protective polyimide film—acts as insulation, replacing the solder mask found in rigid PCBs.

Compared to rigid PCBs, fpc flexible pcb designs are thinner, lighter, and capable of withstanding dynamic movements without breaking. They are available in single-sided, double-sided, and multi-layer formats, offering varying levels of complexity and routing density to suit different application needs.

Materials Used in Flexible PCBs

The performance and reliability of an fpc flexible pcb heavily depend on the materials used in its construction. Each layer plays a critical role in ensuring flexibility, durability, and electrical performance in demanding environments.

The base material is typically polyimide (PI) or polyester (PET). Polyimide is the most commonly used due to its excellent thermal stability, chemical resistance, and mechanical strength, making it ideal for high-performance fpc flexible pcb applications. PET is more cost-effective and used in simpler or lower-temperature applications.

The copper foil used can be either Electrodeposited (ED) or Rolled Annealed (RA). ED copper is more economical but less flexible, while RA copper offers superior ductility, making it suitable for circuits that require repeated bending.

Adhesives are applied between layers to enhance bond strength and flexibility. Coverlay film, usually made of polyimide with adhesive backing, serves as a protective layer over the circuitry, replacing the traditional solder mask used in rigid boards.

To add mechanical support in specific areas, stiffeners such as FR4, aluminum, or stainless steel are incorporated. These materials strengthen connectors or mounting regions without sacrificing the overall flexibility of the fpc flexible pcb.

Manufacturing Process of FPC Flexible PCB

The manufacturing of an fpc flexible pcb involves several precise steps to ensure reliability and performance in dynamic applications:

-

Circuit Design

Engineers use CAD tools to lay out flexible traces, bend lines, and stiffener locations, defining single-sided, double-sided, or multilayer stack-ups. -

Imaging

A photoresist is applied and exposed under UV light through a photomask, transferring the circuit pattern onto the copper foil. -

Etching

Chemical etchants remove unwanted copper, leaving only the designed conductive traces on the flexible substrate. -

Drilling

Laser or mechanical drilling creates vias and through-holes; multilayer FPCs often require microvias for high-density interconnects. -

Plating

Copper plating builds up conductive walls in vias and enhances trace thickness for better current capacity. -

Coverlay Lamination

A polyimide-based coverlay is adhesively bonded to protect traces, replacing the solder mask used in rigid boards. -

Laser Cutting

Precision lasers contour the board outline, cut slots, and form bend lines without mechanical stress. -

Testing

Electrical tests (e.g., flying probe) verify continuity and isolation before delivery.

Process Variations

-

Single-layer FPCs require simpler etch and coverlay steps.

-

Double-layer FPCs add through-hole plating and adhesive film between layers.

-

Multilayer FPCs need controlled lamination and microvia drilling to align multiple copper layers.

SMT on Flexible Boards

Surface Mount Technology on flexible substrates presents challenges such as board warpage and solder joint reliability. Best practices include using stiffeners at component sites, designing proper solder fillets, and controlling reflow profiles to minimize thermal stress.

Advantages of FPC Flexible PCB

The fpc flexible pcb offers numerous advantages that make it an ideal choice for modern electronic applications where traditional rigid boards fall short. Its unique properties enable engineers to design more compact, reliable, and durable products.

One of the most notable features of flexible printed circuits is their excellent bendability and foldability. They can be twisted, curved, or folded without damaging the circuit, making them perfect for dynamic or irregularly shaped assemblies. This flexibility allows them to fit into tight spaces where rigid PCBs cannot.

Another key benefit is that these circuits are lightweight and space-saving. With their thin profile and minimal mass, they significantly reduce the size and weight of the final product—ideal for portable electronics and aerospace devices.

FPC flexible pcb provides high resistance to heat, chemicals, and vibration, making it highly durable even in harsh operating environments such as automotive or industrial applications.

Because of its design versatility, it also reduces the need for connectors and interconnects, streamlining internal layouts and minimizing points of mechanical failure.

An fpc flexible pcb enhances signal integrity and reliability, especially in high-speed or high-density electronic systems. Its shorter routing paths and consistent impedance control help maintain stable electrical performance, even in complex circuit assemblies.

Common Applications of FPC Flexible PCB

The versatility and performance of fpc flexible pcb technology have made it an essential component in a wide range of industries. Its ability to withstand movement, heat, and space limitations allows it to support cutting-edge innovations across consumer, medical, automotive, industrial, and aerospace fields.

In consumer electronics, flexible printed circuits are widely used in smartphones, tablets, cameras, and wearables. Their lightweight and foldable nature enables manufacturers to design slimmer and more ergonomic devices while maintaining high functionality. The flexible interconnects support compact internal layouts and enhance product durability.

In medical devices, these flexible circuits play a critical role in heart monitors, biosensors, and implantable electronics. Their biocompatibility, flexibility, and miniaturization capabilities are ideal for wearable or internal applications where rigid boards would be impractical or uncomfortable.

In the automotive sector, flexible circuits are applied in LED lighting systems, infotainment displays, and radar systems. These boards can adapt to curved surfaces and withstand high temperatures and vibrations, improving long-term reliability in demanding driving conditions.

For industrial equipment, flexible circuits support robotic arms and automation systems by allowing movement without mechanical failure. They enable dynamic components to operate efficiently and continuously in harsh factory environments.

In aerospace and defense, flexible circuits are used in satellites, avionics, and communication modules. Their lightweight structure and resistance to extreme conditions make them ideal for high-reliability applications where space and performance are both critical.

Challenges and Design Considerations of FPC Flexible PCB

Designing and deploying an fpc flexible pcb involves several challenges that engineers must address to ensure long-term performance and reliability:

-

Higher Manufacturing Costs

Compared to rigid PCBs, an fpc flexible pcb uses more expensive base materials (e.g., polyimide) and requires precise processing steps such as laser cutting and coverlay lamination. These specialized materials and tighter tolerances drive up per-unit costs, especially for low-volume production. -

Mechanical Durability Concerns

Although flexible by design, an fpc flexible pcb can suffer from fatigue when bent repeatedly at the same location. Designers must carefully specify minimum bend radii, avoid sharp creases, and consider the number of flex cycles to prevent copper trace cracking over time. -

Flexible Circuit-Specific Design Rules

Standard PCB rules do not apply directly to an fpc flexible pcb. Trace widths need adjustment for dynamic bending, and pad geometries must accommodate coverlay openings. Strategic placement of stiffeners and strain-relief zones is essential to maintain electrical integrity. -

Managing Thermal Performance and EMI Shielding

The thin substrates of an fpc flexible pcb can lead to hot spots under high-power components, requiring thermal vias or dedicated heat spreaders. Additionally, the absence of a solid ground plane in single-layer flex structures makes EMI management more challenging; designers often integrate shielding layers or copper pours to mitigate noise.

By addressing these considerations—cost, durability, tailored design rules, and thermal/EMI strategies—engineers can fully leverage the benefits of flexible circuits without compromising on quality.

Flexible PCBs vs. Rigid-Flex PCBs in FPC Flexible PCB Design

While fpc flexible pcb technology is widely used on its own, it is often compared with rigid-flex PCBs, which combine both flexible and rigid board sections in a single integrated design.

A rigid-flex PCB consists of one or more flexible layers laminated together with rigid boards. These are interconnected internally, forming a unified circuit that allows for both bendable and static sections. This structure offers design versatility by allowing the rigid parts to host connectors or heavy components, while the flexible segments accommodate folding or movement.

When comparing fpc flexible pcb and rigid-flex PCBs, several key differences emerge:

-

Design Complexity: A pure flexible PCB is generally simpler to design than rigid-flex boards, which require precise alignment between rigid and flexible zones and more complex stack-up planning.

-

Cost: Rigid-flex PCBs are typically more expensive due to their multi-stage manufacturing and integration of different materials.

-

Durability: Rigid-flex PCBs provide better mechanical support for components, while standalone flexible circuits often need extra stiffeners for reinforcement.

-

Flexibility: Pure flexible circuit solutions offer maximum flexibility, making them ideal for dynamic or moving parts, whereas rigid-flex designs are better suited for static foldable applications requiring structural support.

Use pure flexible circuits when bendability and light weight are key—like in wearables, sensors, or compact cameras. Opt for rigid-flex PCBs for high-density, durable designs with fewer interconnects—ideal for aerospace, military, and medical 3D assemblies.

Choosing the Right FPC Flexible PCB Manufacturer

Selecting the right partner for your fpc flexible pcb project is crucial to ensure high-quality production, timely delivery, and overall success. When evaluating manufacturers, consider several key capabilities and services:

-

Minimum Trace/Space: The manufacturer should support fine-line circuits with tight trace widths and spacing, critical for advanced fpc flexible pcb designs that require high density and precision.

-

Tolerance Control: Consistent dimensional accuracy and tight tolerances in thickness, hole size, and layer registration are essential to meet design specifications and ensure reliable flex performance.

-

Layer Count Support: Depending on your application, choose a manufacturer that can handle the number of layers your fpc flexible pcb requires, whether single-sided, double-sided, or complex multilayer constructions.

-

Material Certifications: Verify that the manufacturer uses certified materials compliant with industry standards like UL, RoHS, and ISO. These certifications ensure safety, environmental compliance, and product reliability.

-

Prototyping vs. Mass Production Services: Some manufacturers specialize in rapid prototyping to accelerate design validation, while others focus on scalable mass production with cost efficiency. Choose one that fits your project phase and volume needs.

-

SMT Assembly and Post-Production Support: Integrated assembly services, including surface mount technology (SMT) on flexible substrates, and thorough post-production testing help streamline your manufacturing process and reduce time-to-market.

By focusing on these factors, you can choose a manufacturer that meets your technical needs and ensures reliable product performance.

Future Trends in FPC Flexible PCB

The future of fpc flexible pcb technology is bright and rapidly evolving, driven by emerging markets and advancements in electronics. Increasing demand in fields such as the Internet of Things (IoT), 5G communications, and flexible display technologies is pushing the boundaries of what fpc flexible pcb can achieve.

One key trend is the development of ultra-thin FPCs, which allow even greater miniaturization and flexibility for compact devices. Combined with advancements in High Density Interconnect (HDI) technology, these boards can accommodate finer circuitry and more complex signal routing, enabling faster and more powerful electronic systems.

The integration of fpc flexible pcb with wearable technology and biomedical devices is another significant growth area. Flexible PCBs enable lightweight, comfortable, and highly functional wearables that monitor health metrics or assist medical treatments. Their conformability and biocompatibility make them ideal for implantable sensors and flexible diagnostic tools.

As electronics grow more interconnected and portable, flexible PCBs will play a larger role, enabling advanced designs that improve connectivity, performance, and user experience in next-gen applications.