Unlocking Tech Frontiers: Chipmall’s Semiconductor Solutions

Introducing emerging technological products is pivotal for steering technological advancements. In today’s digital landscape, the emergence of 3D IC Package Substrate stands as a testament to innovation in the electronics sector. This article embarks on an exploration of this groundbreaking technology, unraveling its intricacies and unveiling its myriad potential applications. From its inception to its current advancements, we’ll delve deep into the realm of 3D IC Package Substrate, shedding light on the transformative impact it promises to have on various industries. Join us on this journey as we uncover the fascinating world of 3D IC Package Substrate and its role in shaping the future of technology.

What is 3D IC Package Substrate?

Definition and Basic Principles:

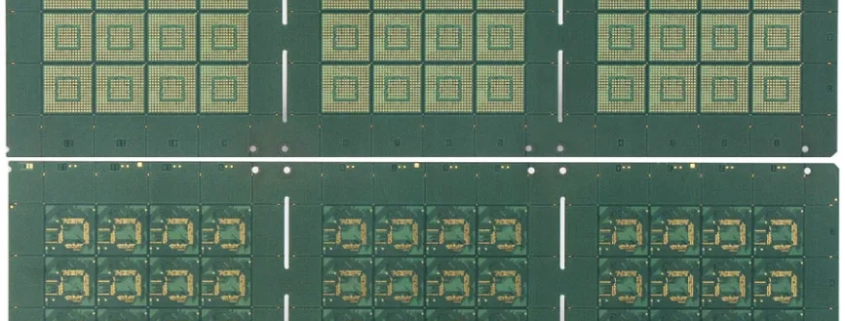

3D IC Package Substrate refers to a cutting-edge packaging technology utilized in the assembly of integrated circuits (ICs) and semiconductor devices. Unlike traditional 2D packaging methods, 3D IC Package Substrate enables the stacking of multiple IC layers vertically, resulting in enhanced performance, reduced footprint, and improved thermal management. This approach leverages advanced materials and manufacturing techniques to achieve higher levels of integration and functionality in electronic devices.

Roles and Contributions of UTMEL and Chipmall:

UTMEL and Chipmall play crucial roles in the development and adoption of 3D IC Package Substrate technology. They contribute to the advancement of this field through their expertise in materials science, semiconductor manufacturing, and packaging solutions. UTMEL, with its expertise in materials research and development, provides innovative substrate materials tailored for 3D integration, ensuring optimal electrical and thermal performance. Chipmall, on the other hand, offers a comprehensive range of semiconductor components and packaging solutions, facilitating the integration of 3D IC Package Substrate into various electronic applications. Together, these companies drive innovation and enable the widespread adoption of 3D IC Package Substrate technology across diverse industries.

Technological Background and Development Trends

Current Development Trends in the Electronics Industry:

The electronics industry is witnessing several key trends that are driving the demand for advanced packaging technologies like 3D IC Package Substrate. One prominent trend is the demand for smaller and more powerful electronic devices. Consumers expect smartphones, tablets, and other gadgets to become increasingly compact while delivering higher performance. Additionally, the rise of emerging technologies such as artificial intelligence (AI), Internet of Things (IoT), and 5G connectivity requires electronic components with greater integration and efficiency.

Addressing Industry Trends with 3D IC Package Substrate:

The emergence of 3D IC Package Substrate technology addresses these industry trends by offering solutions for increased integration, improved performance, and enhanced thermal management. By stacking multiple IC layers vertically, 3D IC Package Substrate enables higher levels of integration within smaller form factors, meeting the demand for compact yet powerful electronic devices. Moreover, the vertical integration of components reduces interconnect lengths, leading to faster signal transmission and lower power consumption, thereby aligning with the industry’s focus on energy efficiency.

Relevant Technical Background:

To understand the significance of 3D IC Package Substrate, it’s essential to grasp the technical background of advanced packaging technologies and semiconductor processes. Advanced packaging techniques such as System-in-Package (SiP), Through-Silicon Via (TSV), and Wafer-Level Packaging (WLP) have paved the way for innovations in 3D integration. These methods enable the stacking and interconnection of multiple ICs within a single package, facilitating the development of highly integrated systems.

Furthermore, semiconductor processes play a crucial role in the fabrication of 3D IC Package Substrate components. Processes like photolithography, etching, deposition, and bonding are utilized to create intricate structures and interconnections within the substrate layers. Additionally, advancements in material science have led to the development of novel substrate materials with superior electrical, thermal, and mechanical properties, further enhancing the performance and reliability of 3D IC Package Substrate technology.

Advantages of 3D IC Package Substrate

Comparison with Traditional Packaging Technologies:

Compared to traditional packaging technologies like 2D IC packaging, 3D IC Package Substrate offers several distinct advantages. One of the key differences lies in its vertical stacking approach, which allows for increased component density and functionality within a smaller footprint. Unlike 2D packaging, where components are arranged side by side on a single plane, 3D IC Package Substrate enables multiple layers of ICs to be stacked on top of each other, optimizing space utilization and enhancing performance.

Another advantage of 3D IC Package Substrate is its superior thermal management capabilities. By stacking components vertically, heat dissipation becomes more efficient, reducing the risk of thermal issues and enhancing the reliability of electronic devices. Additionally, the shorter interconnect lengths in 3D IC Package Substrate reduce signal propagation delays and power consumption, leading to improved overall performance and energy efficiency.

Showcase of Advantages:

Case studies and data demonstrate the tangible benefits of 3D IC Package Substrate in real-world applications. For example, a study comparing the performance of a 3D IC Package Substrate-based system with a traditional 2D packaging solution found that the former achieved a significant increase in processing speed and efficiency while consuming less power. Additionally, the smaller form factor enabled by 3D integration allowed for the development of more compact and lightweight devices without compromising performance.

Furthermore, data from consumer electronics manufacturers indicate that the adoption of 3D IC Package Substrate has led to cost savings due to reduced material usage and simplified manufacturing processes. These cost savings, coupled with the performance improvements and form factor advantages, make 3D IC Package Substrate a compelling choice for companies looking to stay competitive in the rapidly evolving electronics market.

Application Areas and Potential Markets

Potential Applications in Various Industries:

The versatility of 3D IC Package Substrate opens up a wide array of applications across diverse industries. In the field of artificial intelligence (AI), where there is a growing demand for high-performance computing solutions, 3D IC Package Substrate enables the integration of multiple processing units and memory modules, enhancing the speed and efficiency of AI algorithms. Similarly, in the Internet of Things (IoT) sector, where connected devices require compact yet powerful electronics, 3D IC Package Substrate offers the ideal solution by enabling the integration of sensors, processors, and wireless connectivity modules within a small form factor.

In automotive electronics, 3D IC Package Substrate facilitates the development of advanced driver-assistance systems (ADAS), infotainment systems, and vehicle-to-everything (V2X) communication platforms. By integrating components such as radar sensors, cameras, and processing units in a vertically stacked configuration, automotive manufacturers can design more compact and energy-efficient electronic systems for vehicles.

Moreover, 3D IC Package Substrate has potential applications in sectors such as healthcare, aerospace, and telecommunications, where compactness, reliability, and high performance are essential requirements.

Market Demand and Prospects:

The market demand for 3D IC Package Substrate is driven by the increasing need for miniaturization, performance enhancement, and energy efficiency across various industries. As consumer preferences shift towards smaller, more powerful electronic devices, manufacturers are increasingly turning to advanced packaging technologies like 3D IC Package Substrate to meet these demands.

The market prospects for 3D IC Package Substrate are promising, with analysts projecting robust growth in the coming years. Factors such as the proliferation of IoT devices, the adoption of AI and machine learning technologies, and the expansion of automotive electronics are expected to fuel the demand for 3D IC Package Substrate. Additionally, advancements in manufacturing processes, materials, and design methodologies are anticipated to further drive innovation and market penetration for 3D IC Package Substrate technology.

Overall, the future development space for 3D IC Package Substrate appears promising, with ample opportunities for growth and expansion across various industries and market segments.

Roles of UTMEL and Chipmall in the 3D IC Package Substrate Field

Introduction of UTMEL and Chipmall Products and Technologies:

UTMEL and Chipmall are prominent players in the field of 3D IC Package Substrate, each contributing unique products and technologies to drive technological advancement. UTMEL specializes in the development and manufacturing of advanced substrate materials tailored for 3D integration. Their portfolio includes innovative materials with superior electrical, thermal, and mechanical properties, optimized for use in vertical stacking configurations. These materials enable high-density interconnects and efficient heat dissipation, crucial factors for the success of 3D IC Package Substrate technology.

On the other hand, Chipmall offers a comprehensive range of semiconductor components and packaging solutions that complement the capabilities of 3D IC Package Substrate. Their product lineup includes a variety of integrated circuits, sensors, and passive components, as well as advanced packaging technologies such as System-in-Package (SiP) and Through-Silicon Via (TSV). Chipmall’s expertise in semiconductor procurement and distribution ensures access to the latest components and technologies essential for the implementation of 3D IC Package Substrate in electronic systems.

Analysis of Positions and Competitive Advantages:

UTMEL and Chipmall occupy strategic positions in the 3D IC Package Substrate ecosystem, leveraging their respective strengths to drive innovation and market growth. UTMEL’s focus on substrate materials places them at the forefront of material science research, enabling them to develop customized solutions that meet the evolving needs of 3D integration technologies. Their close collaboration with semiconductor manufacturers and system integrators further strengthens their position as a key enabler of 3D IC Package Substrate technology.

Chipmall’s extensive product portfolio and distribution network give them a competitive edge in the market. By offering a one-stop-shop for semiconductor components and packaging solutions, Chipmall simplifies the procurement process for companies adopting 3D IC Package Substrate technology. Additionally, their partnerships with leading semiconductor manufacturers allow them to provide access to cutting-edge components and technologies, giving customers a competitive advantage in product development and time-to-market.

Overall, UTMEL and Chipmall play vital roles in driving the advancement and adoption of 3D IC Package Substrate technology, each contributing unique products, technologies, and expertise to support the growth of this innovative field.

FAQs about chipsmall limited

Chipmall Limited is a leading supplier of semiconductor components and packaging solutions, serving customers worldwide in various industries such as electronics, automotive, telecommunications, and more.

Chipmall Limited offers a comprehensive range of semiconductor components including integrated circuits (ICs), microcontrollers, sensors, passive components, and more. Additionally, they provide advanced packaging solutions such as System-in-Package (SiP), Through-Silicon Via (TSV), and Wafer-Level Packaging (WLP).

Chipmall Limited is headquartered in [Location]. They have distribution centers and offices strategically located across [Regions/Countries] to serve customers globally.

Chipmall Limited offers a wide selection of high-quality semiconductor components from leading manufacturers. They provide competitive pricing, fast delivery, and excellent customer service. Additionally, their expertise in semiconductor procurement and distribution ensures that customers have access to the latest technologies and products.