BGA Package: The Backbone of Modern Electronics

BGA packages revolutionize PCB design and manufacturing with their pivotal role and extensive application scope. These packages, short for Ball Grid Array, have become indispensable in modern electronic systems due to their compactness, high density, and superior electrical performance. In this article, we delve into the significance of BGA packaging in PCB design and manufacturing processes. We explore various aspects, including types, sizes, composition, manufacturing processes, and future trends of BGA packages. By comprehensively examining these topics, we aim to provide a holistic understanding of BGA packages and their crucial role in advancing electronic technology.

Introduction to BGA Packaging

Full name and definition of BGA packaging

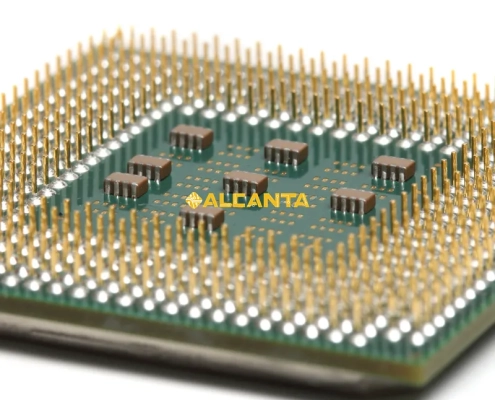

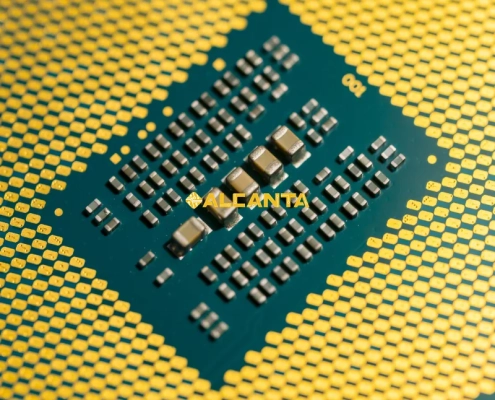

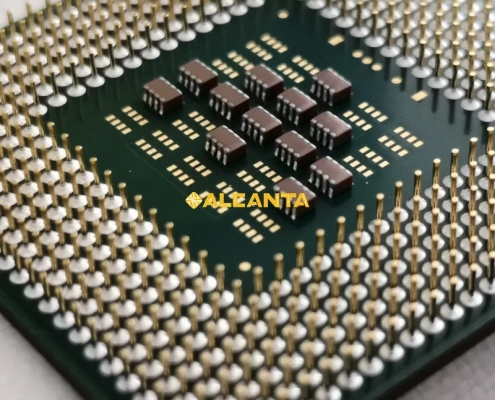

The Ball Grid Array Package, commonly referred to as BGA packaging, is an advanced integrated circuit packaging technology used in electronic devices. In a BGA package, the integrated circuit (IC) is mounted onto a substrate, and the connection to the printed circuit board (PCB) is established through an array of solder balls arranged in a grid pattern on the underside of the package. This packaging technique provides a dense and reliable connection between the IC and the PCB, offering numerous advantages over traditional packaging methods.

Comparison of BGA packaging with traditional packages such as QFN packaging

Compared to traditional packages like Quad Flat No-leads (QFN), BGA packaging offers several advantages. While QFN packages use leads around the perimeter of the package, BGA packages utilize solder balls underneath the package, allowing for more connections in a smaller footprint. This results in higher component density, reduced signal distortion, and improved thermal performance. Additionally, BGA packages offer better electrical performance at high frequencies due to shorter interconnect lengths.

Advantages and characteristics of BGA packaging

BGA packaging presents several key advantages and characteristics. Firstly, its compact size and high component density enable designers to create smaller and more lightweight electronic devices, making it ideal for applications where space is limited. Secondly, the solder balls provide a more robust and reliable connection, reducing the risk of solder joint failures, especially in environments with temperature variations or mechanical stress. Furthermore, BGA packages offer enhanced electrical performance, lower parasitic inductance, and better signal integrity, making them suitable for high-speed and high-frequency applications such as microprocessors, memory chips, and communication devices. Additionally, the uniform thermal distribution across the package ensures efficient heat dissipation, contributing to improved device reliability and longevity. Overall, BGA packaging represents a significant advancement in packaging technology, addressing the demands of modern electronic systems for higher performance, reliability, and miniaturization.

Types and Sizes of BGA Packages

Composition of BGA Packages

Main components of BGA packages

Ball Grid Array Packages consist of several essential components, each contributing to the functionality and reliability of the package. The primary components include:

- Substrate: The substrate serves as the foundation of the Ball Grid Array Package, providing mechanical support and electrical connections between the integrated circuit (IC) and the printed circuit board (PCB). It is typically made of materials like FR-4 (fiberglass-reinforced epoxy) or ceramic, depending on the desired thermal and electrical properties.

- Solder Balls: Solder balls are small spheres of solder alloy attached to the underside of the Ball Grid Array Package. They serve as the interface between the IC and the PCB, providing electrical connections and mechanical support. Solder balls are typically made of tin-lead (SnPb) or lead-free alloys such as tin-silver-copper (SnAgCu) for RoHS compliance.

- Die: The die, also known as the chip or integrated circuit (IC), contains the active components of the electronic device, such as transistors, capacitors, and resistors. It is mounted on the substrate and connected to the solder balls via wire bonds or flip-chip bonding.

- Encapsulation: The encapsulation material surrounds the die and wire bonds, providing protection against environmental factors such as moisture, dust, and mechanical stress. It can be made of plastic (for plastic Ball Grid Array Packages) or ceramic (for ceramic Ball Grid Array Packages), offering different levels of thermal conductivity and mechanical strength.

Internal structure and working principle of BGA packages

Internally, Ball Grid Array Packages feature a layered structure designed to optimize electrical performance, thermal management, and mechanical reliability. The die is mounted on the substrate and connected to it through wire bonds or flip-chip bonding, depending on the package type. The solder balls are then attached to the underside of the substrate, forming an array of electrical connections between the die and the PCB. During assembly, the Ball Grid Array Package is soldered to the PCB using reflow soldering techniques, where the solder balls melt and form solid joints with the PCB pads.

The working principle of Ball Grid Array Packages relies on the reliable electrical connections established between the die and the PCB through the solder balls. These connections facilitate the transmission of electrical signals between the IC and other components on the PCB, allowing the electronic device to function as intended. Additionally, the thermal conductivity of the substrate and encapsulation material helps dissipate heat generated by the IC, ensuring optimal operating conditions and preventing thermal damage. Overall, the internal structure and working principle of Ball Grid Array Packages are designed to maximize performance, reliability, and longevity in electronic devices.

Manufacturing Process of BGA Packages

Overview of the manufacturing process of BGA packages

The manufacturing process of BGA packages involves several intricate steps to ensure the quality, reliability, and functionality of the final product. This process typically includes substrate fabrication, die attachment, wire bonding or flip-chip bonding, solder ball attachment, encapsulation, and package testing.

Key steps including substrate fabrication, solder ball attachment, and package testing

- Substrate Fabrication: The manufacturing process begins with the fabrication of the substrate, which serves as the base for the BGA package. Substrates are typically made of materials such as FR-4 or ceramic. The substrate is fabricated using processes such as lamination, drilling, and etching to create the desired circuitry and pad patterns.

- Die Attachment: Once the substrate is fabricated, the next step is to attach the integrated circuit (IC) die onto the substrate. This process involves applying a layer of adhesive material onto the substrate, placing the die onto the adhesive, and curing the adhesive to securely bond the die to the substrate.

- Wire Bonding or Flip-Chip Bonding: After the die is attached, wire bonding or flip-chip bonding is performed to establish electrical connections between the die and the substrate. In wire bonding, thin wires are bonded from the die’s bond pads to corresponding pads on the substrate using ultrasonic or thermosonic bonding techniques. In flip-chip bonding, the IC is flipped upside down and aligned with the substrate, and solder bumps are used to create electrical connections between the die and the substrate.

- Solder Ball Attachment: Once the electrical connections are established, solder balls are attached to the underside of the substrate using methods such as solder paste stencil printing or solder ball placement machines. The solder balls are then reflowed to create reliable electrical connections between the BGA package and the PCB.

- Encapsulation: After the solder balls are attached, the entire BGA package is encapsulated with a protective material such as plastic or ceramic. This encapsulation provides mechanical support and protection against environmental factors such as moisture and mechanical stress.

- Package Testing: Finally, the BGA packages undergo rigorous testing to ensure their functionality, reliability, and quality. This testing includes electrical tests to verify the integrity of the electrical connections, thermal tests to evaluate the package’s thermal performance, and mechanical tests to assess its mechanical strength and durability.

By meticulously following these key steps in the manufacturing process, BGA packages are produced with high precision and quality, meeting the stringent requirements of modern electronic devices.

Application of BGA Packages in PCB Design

Role and importance of BGA packages in modern PCB design

BGA packages play a pivotal role in modern PCB design, offering numerous advantages that make them indispensable in various electronic applications. One of the key roles of BGA packages is their ability to achieve high component density on the PCB. With their compact size and dense arrangement of solder balls, BGA packages allow designers to incorporate more functionality into smaller PCB footprints, enabling the development of sleeker and more compact electronic devices. Additionally, BGA packages provide superior electrical performance compared to traditional packaging methods, making them ideal for high-speed and high-frequency applications such as microprocessors, memory modules, and communication devices. Furthermore, the robust electrical connections and uniform thermal distribution offered by BGA packages contribute to enhanced reliability and longevity of electronic systems, reducing the risk of solder joint failures and thermal damage.

Relationship between BGA packages and PCB performance, density, and power consumption

The adoption of BGA packages in PCB design has a significant impact on various aspects of PCB performance, density, and power consumption. Firstly, BGA packages enable designers to achieve higher performance levels by minimizing signal distortion and reducing parasitic capacitance and inductance. This results in improved signal integrity, lower electromagnetic interference (EMI), and higher data transmission rates, leading to enhanced overall system performance. Secondly, BGA packages contribute to increased PCB density by allowing for tighter component spacing and higher interconnection density. This facilitates the integration of more functionality into smaller PCB areas, enabling the development of compact and feature-rich electronic devices. However, it’s essential to note that while BGA packages offer higher component density, they may also pose challenges in terms of PCB layout and routing complexity. Lastly, BGA packages can influence power consumption in electronic devices by optimizing thermal management and reducing energy losses. The efficient heat dissipation provided by BGA packages helps maintain optimal operating temperatures, preventing overheating and reducing the need for active cooling systems. Overall, the adoption of BGA packages in PCB design contributes to improved performance, increased density, and optimized power consumption in modern electronic systems.

Future Trends of BGA Packages

Development Trends and Prospects of BGA Packaging Technology

- Miniaturization: The trend towards smaller, more compact electronic devices will drive further miniaturization of BGA packages. Advancements in manufacturing techniques will enable the production of BGA packages with even smaller sizes and finer pitches, allowing for greater component density on PCBs.

- High-Density Interconnects: BGA packages will continue to evolve to accommodate increasing pin counts and higher data transfer rates. This will involve the development of advanced interconnection technologies, such as microvias and high-density routing, to support the growing demands of high-performance applications.

- Enhanced Electrical Performance: Future BGA packages will focus on improving electrical performance by reducing parasitic capacitance and inductance. This may involve the adoption of advanced materials with lower dielectric constants and the integration of innovative packaging techniques, such as embedded passives and advanced routing architectures.

- Improved Thermal Management: As electronic devices become more powerful and compact, effective thermal management will be critical to prevent overheating and ensure reliability. Future BGA packages will incorporate advanced thermal management solutions, such as embedded heat sinks, thermal vias, and liquid cooling systems, to dissipate heat efficiently.

- Enhanced Reliability: With the increasing complexity of electronic systems, ensuring the reliability of BGA packages will be paramount. Future trends may include the implementation of advanced testing and inspection techniques, such as 3D X-ray inspection and automated optical inspection, to detect defects and ensure high-quality solder joints.

- Integration with Emerging Technologies: BGA packages will continue to play a vital role in enabling emerging technologies such as 5G, artificial intelligence (AI), and Internet of Things (IoT). Future innovations may involve the integration of BGA packages with heterogeneous integration techniques, such as system-in-package (SiP) and chiplet-based designs, to create more powerful and efficient electronic systems.

Predictions for Possible Innovations and Improvements in BGA Packaging in the Future

- Advanced Materials: The development of new materials with enhanced thermal and electrical properties will enable the creation of BGA packages with improved performance and reliability. This may include the use of novel substrate materials, advanced solder alloys, and innovative encapsulation materials.

- Flexible and Stretchable BGA Packages: With the growing demand for flexible and wearable electronics, there may be innovations in BGA packaging to create flexible and stretchable packages. These packages would allow for greater design flexibility and durability in applications such as wearable health monitors and flexible displays.

- Embedded Sensors and Components: Future BGA packages may integrate sensors and passive components directly into the package substrate, allowing for more compact and integrated electronic systems. This could enable new functionalities and applications in areas such as automotive electronics, medical devices, and IoT.

- 3D Stacking and Packaging: Advances in 3D packaging technologies will enable the stacking of multiple BGA packages on top of each other, creating vertically integrated systems with reduced footprint and improved performance. This may involve the use of through-silicon vias (TSVs) and advanced stacking techniques to achieve higher levels of integration and functionality.

- Environmentally Friendly Packaging: There will be a growing focus on environmentally friendly packaging solutions, including the use of lead-free solder alloys, recyclable materials, and sustainable manufacturing processes. Future BGA packages may incorporate eco-friendly design principles to minimize their environmental impact and support sustainability initiatives.

FAQs About BGA Package

What is the BGA package?

The BGA (Ball Grid Array) package is a type of integrated circuit packaging where the connection between the integrated circuit (IC) and the printed circuit board (PCB) is made through an array of solder balls arranged in a grid pattern on the underside of the package. BGA packages offer advantages such as compactness, high component density, and improved electrical performance, making them widely used in modern electronic devices.

What is the difference between PCB and BGA?

A PCB (Printed Circuit Board) is a board made of insulating material with conductive pathways etched or printed on it, used to support and connect electronic components. On the other hand, a BGA package refers to a specific type of integrated circuit packaging where the IC is mounted on a substrate, and the connection to the PCB is made through an array of solder balls underneath the package. While a PCB serves as the foundation for electronic components, a BGA package is one of the types of packaging used to mount integrated circuits onto PCBs.

How is BGA package made?

The manufacturing process of a BGA package involves several steps. It typically starts with the fabrication of the substrate, followed by die attachment, wire bonding or flip-chip bonding, solder ball attachment, encapsulation, and package testing. The substrate serves as the foundation, onto which the integrated circuit die is attached. Electrical connections are then established between the die and the substrate, followed by the attachment of solder balls to create connections with the PCB. Finally, the entire package is encapsulated for protection, and rigorous testing is conducted to ensure functionality and reliability.

What does the BGA stand for?

BGA stands for Ball Grid Array.