Key Advantages of AU/Silver QFN/QFP Lead Frame in Electronics

QFN (Quad Flat No-Lead) and QFP (Quad Flat Package) are two popular surface-mount IC packaging types, each offering distinct advantages. QFP features extended leads on all four sides for easy inspection and soldering, while QFN is a leadless package known for its superior thermal and electrical performance due to direct pad connections to the PCB. In semiconductor packaging, the lead frame plays a crucial role by providing electrical connections and structural support, ensuring efficient signal transmission, heat dissipation, and mechanical stability. Among the various materials used, AU/Silver QFN/QFP Lead Frame is highly preferred due to its excellent electrical conductivity, thermal properties, and resistance to oxidation. Gold (AU) enhances durability and reliability, while silver (Ag) offers a cost-effective solution with strong conductivity, making AU/Silver QFN/QFP Lead Frame the ideal choice for high-performance applications in consumer electronics, automotive, and industrial sectors.

Understanding AU/Silver QFN/QFP Lead Frame and Package Types

What is QFP (Quad Flat Package)?

QFP (Quad Flat Package) is a surface-mount IC package characterized by leads extending from all four sides. These leads make it easier to inspect, solder, and rework, which is particularly beneficial for applications requiring high reliability. The package is available in different lead pitches, making it suitable for a variety of PCB designs.

Structure of QFP

- Thin, flat body made from plastic or ceramic materials

- Gull-wing-shaped leads extending outward for easy PCB mounting

- AU/Silver QFN/QFP Lead Frame used to ensure superior electrical and thermal performance

Applications and Benefits of QFP

QFP is widely used in microcontrollers, automotive electronics, industrial automation, and telecommunications. The key advantages include:

- Easy inspection and reworkability due to exposed leads

- Good electrical performance with stable signal transmission

- Cost-effective manufacturing process

What is QFN (Quad Flat No-Lead Package)?

QFN (Quad Flat No-Lead) is a compact, leadless IC package designed for high-performance applications requiring excellent thermal and electrical conductivity. Unlike QFP, it does not have extended leads; instead, it features metal pads directly attached to the PCB, reducing resistance and improving heat dissipation.

Structure of QFN

- Flat, square or rectangular package with no protruding leads

- Bottom-mounted metal pads for direct PCB connection

- Heat sink or exposed pad at the bottom for better thermal management

- AU/Silver QFN/QFP Lead Frame enhances conductivity and reliability

Applications and Benefits of QFN

QFN is widely used in high-frequency RF applications, consumer electronics, and mobile devices. Its advantages include:

- Smaller size and lower profile for compact designs

- Better thermal dissipation due to exposed pad structure

- Lower parasitic inductance for improved high-speed performance

Key Differences Between QFP and QFN

-

Leaded vs. Leadless Design

- QFP has extended leads, making it easier to inspect and solder.

- QFN uses metal pads instead of leads, reducing signal loss and improving thermal performance.

-

Thermal and Electrical Performance Comparison

- QFN offers superior heat dissipation due to its direct PCB connection.

- The use of AU/Silver QFN/QFP Lead Frame in both packages improves electrical conductivity and reliability. However, QFN benefits more due to its leadless structure, which minimizes signal interference.

Both QFP and QFN serve essential roles in semiconductor packaging, with AU/Silver QFN/QFP Lead Frame playing a crucial role in enhancing their performance, durability, and reliability.

What is a Lead Frame in AU/Silver QFN/QFP Lead Frame Packaging?

Definition and Function in IC Packaging

A lead frame is a crucial component in semiconductor packaging, serving as the structural and electrical foundation for integrated circuits (ICs). It provides a stable framework for mounting the silicon die and establishing electrical connections between the chip and the external circuitry. In AU/Silver QFN/QFP Lead Frame packaging, the lead frame plays a vital role in ensuring signal integrity, power distribution, and efficient heat dissipation.

The primary functions of a lead frame in IC packaging include:

- Mechanical Support: Provides a stable platform for the semiconductor die.

- Electrical Connectivity: Transfers signals between the die and the PCB through bonding wires or solder pads.

- Heat Dissipation: Helps manage thermal output to prevent overheating and improve device reliability.

Materials Used in Lead Frames

The performance of a semiconductor package heavily depends on the material used in the lead frame. Common materials include:

- Copper (Cu) Alloys: Known for their excellent electrical conductivity and mechanical strength.

- Iron-Nickel (Fe-Ni) Alloys: Provide high dimensional stability but have lower thermal conductivity compared to copper.

- Silver (Ag) and Gold (AU) Platings: Used in AU/Silver QFN/QFP Lead Frame packaging to enhance conductivity, oxidation resistance, and solderability.

The AU/Silver QFN/QFP Lead Frame combines these materials to optimize electrical performance while ensuring long-term reliability. Gold (AU) provides superior corrosion resistance and excellent bondability, whereas silver (Ag) offers a cost-effective alternative with good thermal and electrical properties.

Importance of Lead Frame Quality in Package Performance

A high-quality lead frame directly impacts the efficiency, durability, and reliability of semiconductor devices. Key benefits include:

- Improved Electrical Performance: High-conductivity materials like AU and Silver reduce signal loss and enhance power efficiency.

- Enhanced Thermal Management: Efficient heat dissipation prevents performance degradation and extends component lifespan.

- Better Solderability and Bonding Strength: Ensures secure connections between the die, bonding wires, and PCB.

In AU/Silver QFN/QFP Lead Frame packaging, the choice of high-quality lead frame materials significantly improves overall package performance, making it ideal for high-speed, high-reliability applications in consumer electronics, automotive, and industrial sectors.

AU/Silver QFN/QFP Lead Frame: Composition and Properties

Gold (AU) Lead Frame

Composition and Characteristics

Gold (AU) lead frames are typically made from high-purity copper or copper alloys with a thin layer of gold plating. The gold layer is applied using electroplating or selective plating techniques to enhance the electrical and thermal performance of the lead frame. In AU/Silver QFN/QFP Lead Frame packaging, gold plating is often used on critical contact areas to improve bonding quality and prevent oxidation.

Benefits of Gold (AU) Lead Frame

- High Conductivity: Gold is one of the best conductors of electricity, ensuring minimal resistance and high-speed signal transmission.

- Oxidation Resistance: Unlike other metals, gold does not tarnish or corrode, maintaining long-term reliability.

- Superior Wire Bonding Performance: Gold-plated surfaces provide excellent adhesion for wire bonding, ensuring a strong and stable electrical connection.

- Long-Term Reliability: Due to its chemical stability, gold lead frames can withstand harsh environmental conditions, making them ideal for critical applications.

Common Applications

Gold lead frames in AU/Silver QFN/QFP Lead Frame packaging are widely used in:

- High-performance microprocessors and integrated circuits (ICs)

- Aerospace and military-grade electronics requiring extreme reliability

- Medical devices where precision and long-term stability are essential

- High-frequency RF and microwave components for telecommunications

Silver (Ag) Lead Frame

Composition and Characteristics

Silver (Ag) lead frames are typically manufactured using a copper or iron-nickel base material with a silver-plated surface. Silver plating enhances electrical and thermal properties while providing a cost-effective alternative to gold. In AU/Silver QFN/QFP Lead Frame packaging, silver plating is often used in applications that require excellent conductivity at a lower cost.

Benefits of Silver (Ag) Lead Frame

- Cost-Effective: Silver is more affordable than gold while still offering excellent conductivity.

- Good Electrical Performance: Silver has the highest electrical conductivity of all metals, ensuring efficient signal transmission.

- Enhanced Thermal Management: Silver-plated lead frames improve heat dissipation, preventing overheating and extending device lifespan.

- Moderate Oxidation Resistance: While silver can tarnish over time, advanced coating technologies help mitigate this issue.

Common Applications

Silver lead frames in AU/Silver QFN/QFP Lead Frame packaging are commonly used in:

- Consumer electronics, such as smartphones and tablets

- Automotive electronics requiring high thermal efficiency

- LED lighting solutions where thermal management is critical

- Power management ICs and battery control systems

Both gold and silver lead frames play a crucial role in AU/Silver QFN/QFP Lead Frame packaging, with gold offering superior reliability and silver providing an economical yet efficient alternative. The choice between gold and silver lead frames depends on the specific requirements of the application, balancing cost, performance, and longevity.

Comparison: AU vs. Silver Lead Frames in AU/Silver QFN/QFP Lead Frame

When selecting materials for AU/Silver QFN/QFP Lead Frame, it is essential to compare the properties of gold (AU) and silver (Ag) lead frames in terms of electrical and thermal performance, cost, reliability, and application suitability. Both materials offer unique advantages, making them suitable for different semiconductor packaging needs.

Electrical and Thermal Conductivity Differences

Gold (AU) and silver (Ag) are both excellent conductors, but silver surpasses gold in pure electrical conductivity:

- Electrical Conductivity: Silver has the highest electrical conductivity of any metal, meaning it offers slightly lower resistance compared to gold. However, in AU/Silver QFN/QFP Lead Frame packaging, the difference is often negligible due to the thin plating layers used.

- Thermal Conductivity: Silver also outperforms gold in thermal conductivity, making it highly effective for heat dissipation in power electronics and high-performance ICs.

- Performance Impact: While silver provides better electrical and thermal efficiency, gold’s stable conductivity ensures long-term performance, especially in high-reliability applications.

Cost Considerations

Cost plays a major role in determining the choice between gold and silver in AU/Silver QFN/QFP Lead Frame manufacturing:

- Gold (AU) Lead Frames: Gold is significantly more expensive than silver due to its rarity and high demand. This makes AU lead frames costlier, but they provide unmatched durability and reliability, justifying the expense in high-end applications.

- Silver (Ag) Lead Frames: Silver is a cost-effective alternative that delivers high conductivity and thermal efficiency. However, it requires additional processing to mitigate oxidation issues, slightly increasing production costs.

Reliability and Oxidation Resistance

The longevity and stability of AU/Silver QFN/QFP Lead Frame depend on material resistance to oxidation and environmental degradation:

- Gold (AU) Lead Frames: Gold is highly resistant to oxidation and corrosion, making it ideal for harsh environments, aerospace, and medical applications. It maintains its electrical properties over time without degradation.

- Silver (Ag) Lead Frames: Silver is prone to oxidation and tarnishing when exposed to air, which can impact long-term reliability. However, modern anti-tarnish coatings and alloying techniques help minimize these issues, improving durability.

Best Use Cases for Each Material

Both gold and silver lead frames in AU/Silver QFN/QFP Lead Frame packaging serve distinct purposes based on performance and cost requirements:

-

Gold (AU) Lead Frames:

- High-reliability applications (aerospace, medical devices)

- High-frequency RF and microwave circuits

- Mission-critical industrial and defense electronics

- Semiconductor packaging requiring long-term stability

-

Silver (Ag) Lead Frames:

- Cost-sensitive consumer electronics (smartphones, tablets, PCs)

- Automotive electronics requiring high thermal conductivity

- LED lighting and power management ICs

- General-purpose semiconductor applications

In AU/Silver QFN/QFP Lead Frame applications, the choice between gold and silver lead frames depends on the balance between performance, cost, and longevity. Gold excels in high-reliability environments, while silver provides an economical yet efficient alternative for mass-market applications. Understanding these differences allows manufacturers to optimize performance while managing costs effectively.

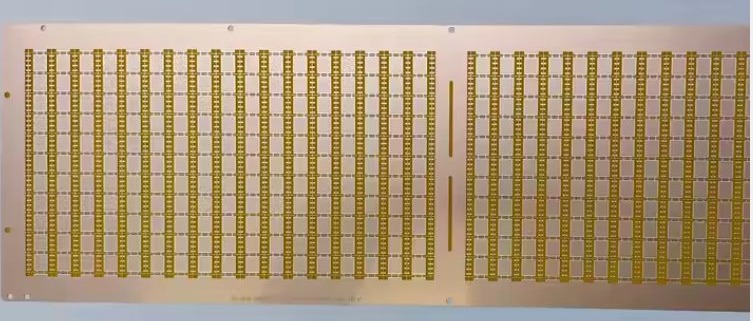

Manufacturing and Thickness of AU/Silver QFN/QFP Lead Frame

The AU/Silver QFN/QFP Lead Frame is a critical component in semiconductor packaging, providing structural integrity, electrical connectivity, and thermal management for integrated circuits (ICs). The manufacturing process of these lead frames requires precision engineering to ensure optimal performance and reliability. This section details the standard thickness of QFN lead frames, the fabrication process of AU/Silver lead frames, and the quality control measures employed in production.

Standard Thickness of QFN Lead Frames

QFN lead frames typically have a thickness ranging between 0.15mm and 0.3mm, depending on the package size, application requirements, and thermal considerations. The selection of thickness plays a crucial role in:

- Mechanical Stability: Thicker lead frames provide better support for large die sizes.

- Thermal Dissipation: A properly sized lead frame ensures efficient heat transfer from the IC to the PCB.

- Electrical Performance: A balance between thickness and conductivity is necessary to minimize resistance while maintaining flexibility for wire bonding or soldering.

In AU/Silver QFN/QFP Lead Frame packaging, manufacturers optimize lead frame thickness based on application needs, ensuring both cost-effectiveness and performance.

Fabrication Process of AU/Silver Lead Frames

The production of AU/Silver QFN/QFP Lead Frame involves several precise manufacturing steps to achieve the required electrical, mechanical, and thermal properties. The key steps include:

- Base Material Selection – Copper or iron-nickel (Fe-Ni) alloy is chosen as the base material due to its excellent conductivity and strength.

- Etching or Stamping – The lead frame pattern is formed using chemical etching or precision stamping, ensuring accurate design dimensions.

- Plating Process:

- Gold (AU) Plating: Applied selectively to bonding areas, ensuring superior wire bonding reliability and corrosion resistance.

- Silver (Ag) Plating: Used for cost-effective conductivity improvements, offering excellent solderability.

- Surface Treatment: To prevent oxidation and enhance durability, protective coatings such as anti-tarnish layers are applied to silver-plated lead frames.

- Singulation and Final Processing: The lead frames are cut into individual units, cleaned, and inspected before packaging for semiconductor assembly.

Quality Control in Lead Frame Production

To ensure the AU/Silver QFN/QFP Lead Frame meets industry standards and application requirements, rigorous quality control measures are implemented:

- Thickness and Dimension Inspection: Advanced measurement tools verify lead frame thickness, ensuring consistency within the 0.15mm–0.3mm range.

- Surface Plating Analysis: The gold and silver layers are tested for uniformity, adhesion, and thickness to prevent defects in wire bonding and soldering.

- Oxidation and Corrosion Testing: Accelerated aging tests are conducted to ensure oxidation resistance, especially for silver-plated lead frames.

- Mechanical Strength Assessment: Stress and bending tests are performed to guarantee the structural integrity of the lead frame during IC assembly.

The AU/Silver QFN/QFP Lead Frame manufacturing process combines advanced materials, precision fabrication, and strict quality control to produce reliable semiconductor packaging solutions. By optimizing thickness, ensuring high-quality gold and silver plating, and adhering to rigorous production standards, these lead frames enhance the performance and longevity of QFN and QFP packages across various industries.

Advantages of AU/Silver QFN/QFP Lead Frame in Semiconductor Packaging

The AU/Silver QFN/QFP Lead Frame plays a crucial role in the performance and reliability of semiconductor devices. By utilizing gold (AU) or silver (Ag) plating, these lead frames enhance electrical conductivity, thermal efficiency, and mechanical durability. This section explores the key advantages of using AU/Silver QFN/QFP Lead Frame in modern integrated circuit (IC) packaging.

Enhanced Electrical Performance of AU/Silver QFN/QFP Lead Frames

One of the primary advantages of the AU/Silver QFN/QFP Lead Frame is its superior electrical conductivity, which directly impacts signal transmission speed and efficiency.

- Low Electrical Resistance: Silver has the highest electrical conductivity among metals, followed by gold. This minimizes resistance and ensures rapid signal propagation.

- Stable Contact Resistance: Gold plating prevents oxidation and corrosion, maintaining consistent electrical connections over time.

- Reduced Signal Loss: The high conductivity of AU/Silver lead frames minimizes power dissipation, making them ideal for high-frequency and high-speed applications such as RF circuits and microprocessors.

Improved Heat Dissipation with AU/Silver QFN/QFP Lead Frame

Thermal management is a critical factor in semiconductor packaging, and the AU/Silver QFN/QFP Lead Frame significantly enhances heat dissipation.

- High Thermal Conductivity: Silver-plated lead frames efficiently transfer heat away from the IC, reducing the risk of overheating and improving performance stability.

- Optimized Package Design: QFN and QFP packages rely on the exposed pad or lead frame to dissipate heat into the PCB. The superior thermal properties of AU/Silver lead frames improve heat spreading, reducing junction temperatures.

- Extended Device Lifespan: Effective heat dissipation prevents thermal stress, reducing the likelihood of premature failure in high-power applications such as power management ICs and automotive electronics.

Increased Package Reliability with AU/Silver QFN/QFP Lead Frame

Reliability is a key concern in semiconductor packaging, and the AU/Silver QFN/QFP Lead Frame provides enhanced durability and long-term stability.

- Corrosion and Oxidation Resistance: Gold plating offers excellent protection against environmental factors, ensuring long-term reliability even in harsh conditions. Silver lead frames, when coated with anti-tarnish layers, also provide extended durability.

- Mechanical Stability: AU/Silver lead frames maintain structural integrity during thermal cycling and mechanical stress, preventing warping or cracking.

- Enhanced Wire Bonding Strength: Gold-plated lead frames improve the adhesion of bonding wires, reducing the risk of delamination or electrical failure over time.

Better Solderability and Bonding Performance of AU/Silver QFN/QFP Lead Frame

The AU/Silver QFN/QFP Lead Frame ensures superior soldering and bonding capabilities, crucial for efficient assembly and long-term package reliability.

- Strong Wire Bonding: Gold plating significantly enhances the adhesion of fine wire bonds, making it the preferred choice for high-precision IC packaging.

- Improved Solder Wettability: Silver-plated lead frames provide excellent solderability, ensuring strong connections between the IC and PCB, which is essential for mass production efficiency.

- Consistent Manufacturing Yields: The high-quality surface finish of AU/Silver lead frames minimizes defects in wire bonding and soldering, reducing production costs and enhancing overall yield rates.

The AU/Silver QFN/QFP Lead Frame offers significant advantages in semiconductor packaging, including superior electrical conductivity, efficient heat dissipation, enhanced reliability, and improved manufacturability. Whether using gold for high-end applications requiring extreme reliability or silver for cost-effective mass production, these lead frames ensure optimal performance and longevity in various electronic devices.

Applications of AU/Silver QFN/QFP Lead Frames in Modern Electronics

The AU/Silver QFN/QFP Lead Frame is widely used in semiconductor packaging due to its excellent electrical conductivity, thermal efficiency, and reliability. These lead frames play a crucial role in ensuring the performance and longevity of various electronic devices across multiple industries. From consumer electronics to automotive applications, medical devices, and industrial telecommunications, the AU/Silver QFN/QFP Lead Frame provides a stable and efficient foundation for advanced integrated circuits (ICs).

Application of AU/Silver QFN/QFP Lead Frames in Consumer Electronics

Consumer electronics demand high-performance semiconductor packaging that ensures efficiency, durability, and miniaturization. The AU/Silver QFN/QFP Lead Frame is a preferred choice due to its ability to support compact, high-speed, and thermally efficient designs.

- Smartphones and Tablets: High-frequency processors, power management ICs, and connectivity modules (Wi-Fi, Bluetooth, 5G) utilize AU/Silver lead frames to optimize signal transmission and reduce heat buildup.

- Laptops and Wearable Devices: The ultra-thin profile and excellent thermal dissipation properties of AU/Silver QFN/QFP Lead Frame enhance the performance of processors, sensors, and memory chips in modern portable electronics.

- Smart Home Appliances: Devices such as smart TVs, home automation systems, and IoT-based gadgets rely on high-reliability lead frames to maintain long-term operational stability.

AU/Silver QFN/QFP Lead Frame in the Automotive Industry

The automotive sector increasingly relies on semiconductor components for safety, efficiency, and performance. The AU/Silver QFN/QFP Lead Frame is essential in vehicle electronics, offering high thermal conductivity and corrosion resistance in demanding environments.

- Advanced Driver Assistance Systems (ADAS): High-speed processors and sensors used in ADAS depend on AU/Silver lead frames to maintain performance under extreme temperature variations.

- Electric Vehicles (EVs) and Power Management ICs: The superior thermal properties of AU/Silver QFN/QFP Lead Frame improve heat dissipation in high-power applications such as battery management systems (BMS) and power inverters.

- Infotainment and Connectivity: Automotive infotainment systems, GPS modules, and communication interfaces require reliable semiconductor packaging to ensure seamless connectivity and operation.

AU/Silver QFN/QFP Lead Frame in Medical Devices

Reliability and precision are critical in medical electronics, making the AU/Silver QFN/QFP Lead Frame a key component in devices used for patient monitoring, diagnostics, and treatment.

- Implantable Medical Devices: Pacemakers, neurostimulators, and other life-saving implants use gold-plated lead frames for their excellent biocompatibility and resistance to corrosion.

- Diagnostic Equipment: High-resolution imaging devices such as MRI, CT scanners, and ultrasound machines rely on AU/Silver QFN/QFP Lead Frame technology for stable signal transmission and power efficiency.

- Portable Medical Devices: Blood glucose monitors, wearable ECG sensors, and portable ventilators utilize QFN/QFP lead frames to ensure compact and reliable semiconductor performance.

Application of AU/Silver QFN/QFP Lead Frame in Industrial and Telecommunications

Industrial automation and telecommunication networks require semiconductor solutions that offer high durability, low power consumption, and stable operation. The AU/Silver QFN/QFP Lead Frame provides these advantages, making it indispensable in these sectors.

- 5G Infrastructure and Networking Equipment: High-frequency RF modules and base station processors use AU/Silver lead frames to maintain low signal loss and high-speed data transmission.

- Industrial Control Systems: Power management ICs and microcontrollers in factory automation and robotics rely on AU/Silver QFN/QFP Lead Frame technology for enhanced reliability and longevity.

- Aerospace and Defense Electronics: Military-grade communication systems, radar modules, and satellite electronics use gold-plated lead frames for superior resistance to oxidation and harsh environmental conditions.

The AU/Silver QFN/QFP Lead Frame plays a vital role in numerous industries, ensuring high-performance, energy-efficient, and durable semiconductor packaging solutions. Whether in consumer electronics, automotive applications, medical devices, or industrial telecommunications, AU/Silver lead frames provide the reliability and efficiency needed for modern technology. Their superior electrical conductivity, thermal management, and long-term stability make them a preferred choice in advanced IC packaging.

Challenges and Future Trends in AU/Silver QFN/QFP Lead Frame Technology

The AU/Silver QFN/QFP Lead Frame has become an essential component in semiconductor packaging, offering superior electrical conductivity, thermal management, and reliability. However, despite its advantages, manufacturers face several challenges, particularly regarding cost-performance trade-offs, material innovations, and the evolving landscape of QFN/QFP packaging technology. This section explores these challenges and highlights the future trends shaping the development of AU/Silver QFN/QFP Lead Frame solutions.

Cost vs. Performance Trade-Offs

One of the most significant challenges in the semiconductor industry is balancing cost and performance. The AU/Silver QFN/QFP Lead Frame provides excellent electrical and thermal properties, but the cost of raw materials—especially gold—poses financial constraints for large-scale production.

- Gold Price Volatility: The high cost of gold makes fully gold-plated lead frames expensive, limiting their use in cost-sensitive applications.

- Silver Tarnishing Issues: While silver is a more cost-effective alternative, it is prone to oxidation and requires additional protective coatings, which increase production complexity.

- Material Substitution Strategies: Manufacturers are exploring mixed-metal solutions, such as selective gold plating or silver-copper alloys, to maintain performance while reducing costs.

Innovations in Lead Frame Materials

To address cost and performance challenges, significant research is being conducted on innovative materials and coating technologies for AU/Silver QFN/QFP Lead Frame manufacturing. Some emerging trends include:

- Hybrid Plating Techniques: Combining gold and silver plating in critical bonding areas while using alternative materials for less-sensitive regions helps optimize cost and reliability.

- Enhanced Anti-Tarnish Coatings: New surface treatment technologies, such as nanocoatings and anti-oxidation films, improve the durability of silver-plated lead frames, making them more suitable for high-reliability applications.

- Copper-Based Lead Frames with Silver or Gold Flashing: Using copper as the base material with a thin layer of gold or silver provides an effective balance between cost savings and performance enhancement.

- Environmentally Friendly Lead Frames: Efforts to develop lead-free, RoHS-compliant lead frame materials are gaining traction as sustainability becomes a key focus in semiconductor manufacturing.

Future Advancements in QFN/QFP Packaging

As electronic devices continue to evolve, QFN/QFP packaging technology is also advancing to meet the demands for higher efficiency, miniaturization, and better thermal performance. The AU/Silver QFN/QFP Lead Frame is expected to adapt to these new trends, including:

- Ultra-Thin and High-Density Packaging: Future QFN/QFP designs will require thinner lead frames with higher pin density to accommodate the increasing complexity of modern ICs.

- Improved Thermal Dissipation Solutions: Next-generation lead frames will integrate enhanced thermal vias, heat spreaders, and advanced metal alloys to further improve heat dissipation in power-intensive applications.

- Integration with 3D Packaging Technologies: As 3D ICs and system-in-package (SiP) solutions gain popularity, AU/Silver lead frames must evolve to support multi-layer stacking and advanced interconnect designs.

- AI and IoT-Driven Applications: The demand for high-performance and energy-efficient semiconductor packaging in AI, IoT, and 5G applications will drive further optimization in AU/Silver QFN/QFP Lead Frame materials and manufacturing processes.

The AU/Silver QFN/QFP Lead Frame remains a cornerstone of modern semiconductor packaging, but manufacturers must navigate cost challenges, material innovations, and evolving industry demands. Future advancements in lead frame technology will focus on optimizing cost-effectiveness, enhancing thermal and electrical properties, and adapting to emerging electronic applications. As new materials and fabrication techniques continue to evolve, AU/Silver lead frames will play a critical role in shaping the next generation of semiconductor packaging solutions.

FQAs Abut AU/Silver QFN/QFP Lead Frame

What is the difference between QFP and QFN?

QFP (Quad Flat Package) and QFN (Quad Flat No-lead Package) are both surface-mount packaging styles, but they have key differences:

- Lead Structure: QFP has leads that extend from all four sides of the package, while QFN has leads underneath the package (no visible leads on the sides).

- Mounting: QFPs are typically mounted with the leads extending outward, while QFNs are mounted with the leads underneath, allowing for a more compact footprint.

- Heat Dissipation: QFNs usually have better thermal performance due to the larger exposed area for heat dissipation (on the bottom side of the package).

- Electrical Performance: QFNs tend to have lower inductance and resistance compared to QFPs due to the direct connection of leads under the package.

What is the difference between QFN and leaded packages?

QFN and leaded packages differ in their lead configuration:

- QFN: Has no leads extending from the sides, with all leads (pads) underneath the package. This provides better thermal performance and smaller form factor.

- Leaded Packages (e.g., QFP, DIP): Have leads extending from the sides (QFP) or through-holes (DIP), making them larger and often more robust for handling during assembly.

- Mounting Process: QFNs are usually soldered directly to the PCB, while leaded packages use soldering of the leads, which might be easier for manual assembly but less compact.

What is the difference between QFN and flip chip?

QFN and flip chip are both types of semiconductor packages, but they differ significantly:

- QFN: The leads (pads) are located underneath the package, making it suitable for surface-mount assembly. It typically has a low profile and is suitable for applications requiring high thermal performance.

- Flip Chip: Involves flipping the chip upside down and directly bonding the die to the PCB with solder bumps or conductive adhesive. It has no traditional lead frame and is used for high-performance applications with very low parasitic inductance and resistance.

- Thermal and Electrical Performance: Flip chip packages typically offer superior performance in terms of electrical speed and heat dissipation due to the direct bond between the chip and PCB, whereas QFNs are more cost-effective and easier to assemble.

How thick is a QFN lead frame?

The typical thickness of a QFN lead frame ranges between 0.15 mm to 0.3 mm. The specific thickness can vary depending on the package size and the application requirements, with thinner lead frames used for smaller or more compact QFN packages.