Materials for high-performance aerospace PCB applications

Aerospace PCBs are specialized printed circuit boards designed for the demanding requirements of aviation, space exploration, and defense applications. Unlike standard commercial PCBs, aerospace-grade boards must operate flawlessly in extreme environmental conditions, withstand high mechanical stress, and meet stringent quality and safety certifications.

From avionics systems in passenger aircraft to communication modules in satellites, these PCBs form the backbone of modern aerospace technology.

Performance Requirements for Aerospace PCBs

Operating in outer space or high-altitude flight environments imposes extreme demands on PCB performance. Key requirements include:

-

High Reliability – Resistance to shock, vibration, and long operational lifetimes without maintenance.

-

Environmental Resistance – Capability to function in temperature ranges from -150°C to +150°C, high humidity, and radiation exposure.

-

Stable Electrical Performance – Maintaining signal integrity at high frequencies, low noise levels, and minimal signal loss.

-

Weight Optimization – Using lightweight materials to reduce total spacecraft mass without compromising structural strength.

Get a Quotation For Aerospace PCB Applications Now

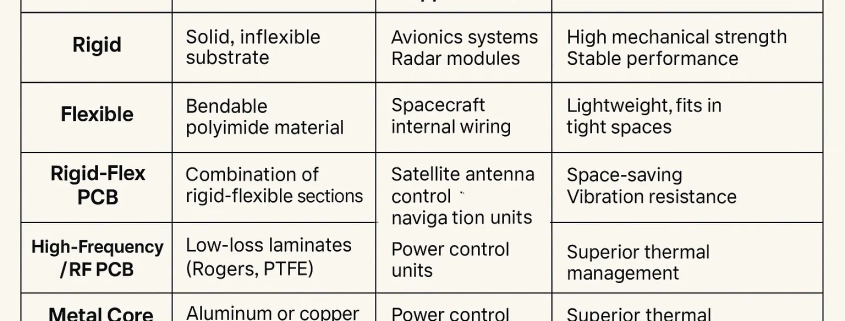

Types of Aerospace PCBs

| PCB Type | Key Features | Typical Applications | Advantages in Aerospace |

|---|---|---|---|

| Rigid PCB | Solid, inflexible substrate | Avionics systems, radar modules | High mechanical strength, stable performance |

| Flexible PCB | Bendable polyimide material | Spacecraft internal wiring | Lightweight, fits in tight spaces |

| Rigid-Flex PCB | Combination of rigid and flexible sections | Satellite antenna control, navigation units | Space-saving, vibration resistance |

| High-Frequency / RF PCB | Low-loss laminates (Rogers, PTFE) | Radar, satellite communication | Excellent signal integrity |

| Metal Core PCB | Aluminum or copper core for heat dissipation | Power control units, propulsion electronics | Superior thermal management |

Get a Quotation For Aerospace PCB Applications Now

Key Applications in the Aerospace Industry

Avionics Systems

-

Flight control computers

-

Flight displays and navigation units

-

Autopilot modules

Communication Systems

-

Satellite transceivers

-

High-frequency radar transmitters

-

Antenna control electronics

Power Management and Distribution

-

Power conditioning units (PCUs)

-

Battery management systems (BMS)

-

High-voltage/low-voltage converters

Propulsion and Control

-

Rocket engine control electronics

-

Thrust vector control modules

-

Fuel pump monitoring systems

Spacecraft & Satellite Systems

-

Solar panel power controllers

-

Data acquisition and processing units

-

Attitude control systems

Get a Quotation For Aerospace PCB Applications Now

Materials and Fabrication Considerations

Aerospace PCBs demand premium materials and advanced manufacturing processes:

-

Substrate Materials – Polyimide for thermal stability, Rogers laminates for low-loss RF performance, and ceramic substrates for extreme conditions.

-

Conductors – High-purity copper, sometimes silver-plated for enhanced conductivity.

-

Surface Finishes – ENIG (Electroless Nickel Immersion Gold) for corrosion resistance, hard gold for connector pads.

-

Solder Mask – High-temperature-resistant and UV-stable coatings.

-

Heavy Copper Design – Supports high current loads in power circuits.

-

Microvia & Buried Via Technology – Enables high-density interconnect (HDI) layouts for compact, complex aerospace modules.

Get a Quotation For Aerospace PCB Applications Now

Aerospace PCB Standards and Certifications

Aerospace electronics manufacturing must comply with strict standards to ensure safety and reliability:

-

IPC-6012DS – Space and military avionics addendum to IPC-6012.

-

MIL-PRF-31032 – U.S. military performance specification for high-reliability PCBs.

-

AS9100 – Quality management system for aerospace manufacturers.

-

NASA Standards – Such as NASA-STD-8739.1 for soldering and workmanship.

Get a Quotation For Aerospace PCB Applications Now

Testing and Quality Assurance in Aerospace PCBs

Each aerospace PCB undergoes extensive validation before deployment:

-

Environmental Testing – Thermal cycling, vacuum chamber simulation, humidity exposure.

-

Mechanical Stress Testing – Vibration and shock resistance validation.

-

Electrical Testing – Functional verification under load conditions.

-

X-ray Inspection – Detects solder joint integrity and hidden defects.