Key Benefits of Advanced Single Sided Substrate in Electronics

In printed circuit board (PCB) design, the substrate serves as the foundational material that supports and electrically insulates conductive traces. A PCB substrate not only provides structural stability but also affects signal integrity, thermal performance, and reliability. Among various types, the single-sided substrate is the most basic, consisting of a single layer of conductive copper laminated to one side of an insulating material—commonly FR-4 or other laminates. While multi-layer substrates offer higher routing density and power handling, single-sided versions are valued for their simplicity, low cost, and ease of manufacturing. However, as packaging demands evolve, the advanced single sided substrate has emerged to meet higher performance needs without the complexity of multilayer stacks. Enhanced by modern materials and precision processes, these substrates play a growing role in compact, high-speed, and thermally demanding applications across sectors such as wearables, automotive electronics, and RF modules, bridging affordability and advanced functionality.

Evolution of advanced single sided substrate Technology

The journey of the advanced single sided substrate began with simple, cost‑effective solutions for mass‑market products. In its early days, single‑layer boards were predominantly used in LED signage, basic consumer electronics like calculators and remote controls, and low‑frequency power supplies. Their straightforward fabrication—copper foil bonded to an FR‑4 or CEM‑1 core—offered reliable performance at minimal cost.

As device miniaturization and higher data rates became critical, demand for higher performance drove substrate innovation. Designers sought better thermal management, tighter line‑space control, and improved dielectric properties. This push led to low‐loss laminates, thin‐film metallization, and precision etching techniques that enhanced signal integrity and reduced electromagnetic interference—all while retaining the single‑layer simplicity.

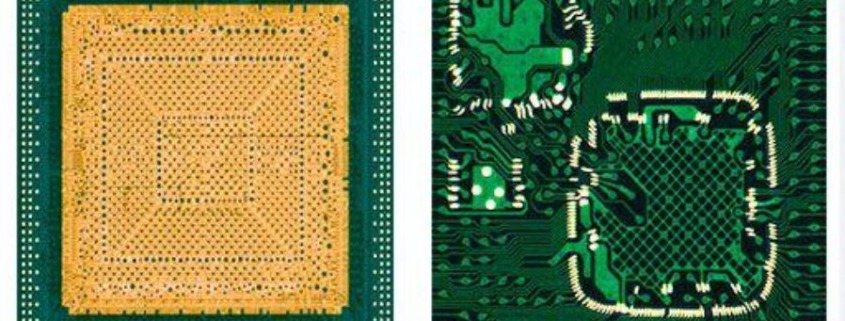

Simultaneously, packaging advancements such as System‑in‑Package (SiP), Flip‑Chip (FC), and Wafer‑Level Chip‑Scale Packaging (WLCSP) influenced substrate requirements. These advanced assembly methods required substrates that could handle finer pitches, support under‑fill materials, and withstand multiple reflow cycles. Modern single‑sided substrates have thus evolved to integrate laser‑drilled microvias and high‐temperature resins, enabling reliable interconnects in compact, high‑density modules without resorting to costly multilayer stacks. As a result, today’s advanced single‑sided substrate bridges legacy simplicity with cutting‑edge packaging demands.

Overview of advanced single sided substrate Materials

This section explores various materials used in advanced single sided substrate designs, highlighting their electrical, thermal, and mechanical properties.

FR‑4

The workhorse of PCB substrates, FR‑4 (woven glass‑epoxy) offers a dielectric constant (εr) around 4.5, low loss, and good mechanical strength. Pros include low cost, wide availability, and easy manufacturability. However, its thermal conductivity (~0.3 W/m·K) and CTE (14–17 ppm/°C) limit performance in high‑power or high‑speed applications.

High‑Frequency Laminates (e.g., Rogers)

Materials like Rogers RO4000 or RO3000 series provide εr between 3.4 and 10 with very low dissipation factors (<0.002). Their improved thermal stability (κ ~0.6 W/m·K) and controlled CTE (~14 ppm/°C) make them ideal for RF and microwave circuits.

Ceramic Substrates

Alumina, aluminum nitride, and beryllia boast high thermal conductivities (20–200 W/m·K) and εr of 9–10. Excellent electrical insulation and minimal warpage are ideal for power modules, but ceramic’s brittleness and higher cost restrict volume use.

Metal‑Core PCBs (MCPCB)

A thin dielectric layer (εr ~4.5) bonded to an aluminum or copper core achieves κ of 2–4 W/m·K. MCPCBs excel in LED lighting and power supplies, balancing improved heat dissipation with moderate CTE (~8 ppm/°C) and mid‑range cost.

Single‑Crystal Substrates

Exotic materials like NdGaO₃ and LaAlO₃ feature εr up to 20 and κ around 8–12 W/m·K, with very low CTE (~6 ppm/°C). Though extremely costly, they enable niche, high‑frequency, and high‑temperature applications.

| Material | Dielectric Constant (εr) | Thermal Conductivity (W/m·K) | CTE (ppm/°C) | Relative Cost |

|---|---|---|---|---|

| FR‑4 | 4.5 | 0.3 | 14–17 | Low |

| Rogers RO4000 (HF Laminates) | 3.4–10 | 0.6 | ~14 | High |

| Ceramic (Al₂O₃, AlN, BeO) | 9–10 | 20–200 | 6–8 | Very High |

| MCPCB (Al/Cu Core) | ~4.5 | 2–4 | ~8 | Medium |

| Single‑Crystal (NdGaO₃, LaAlO₃) | ~20 | 8–12 | ~6 | Very High |

This comparison underscores how material choice directly impacts the performance and cost of an advanced single sided substrate solution.

Key Features of advanced single sided substrate

An advanced single sided substrate brings together simplicity and high performance through several key attributes:

Enhanced Thermal Management for Power Electronics

By incorporating high‑thermal‑conductivity core materials and optimized copper thickness, these substrates dissipate heat efficiently from power transistors, LEDs, and voltage regulators. The result is lower junction temperatures, improved reliability, and extended device lifetimes.

Fine Line/Space Capability for High‑Density Routing

Advanced photoresist formulations and precision etching processes enable line widths and spaces down to 50 µm or below on a single copper layer. This fine patterning allows dense interconnects for compact modules without resorting to multilayer stacks, reducing parasitic effects and signal loss.

Compatibility with Advanced Packaging (Flip‑Chip, Embedded Die)

Surface finishes such as electroless nickel immersion gold (ENIG) and laser‑drilled microvias support flip‑chip attachment and embedded die integration. The substrate’s planar topography and controlled Z‑axis expansion ensure reliable solder joints during multiple reflow cycles.

Mechanical Reliability and Chemical Resistance

High‑performance resins, such as polyimide or benzocyclobutene, offer excellent flexural strength and resistance to solvents, flux chemistries, and cleansers. This durability is critical for harsh environments in automotive, industrial, and medical applications.

Cost‑Performance Optimization

By leveraging mature single‑layer fabrication and selective material enhancements only where needed, manufacturers achieve a balance of low unit cost and high electrical/thermal performance. This makes the advanced single sided substrate an economical choice for volume production of specialized, high‑performance electronics.

Material Innovation Driving advanced single sided substrate Design

Innovation in substrate materials has been pivotal to evolving the advanced single sided substrate into a high‑performance platform:

Polyimide, LCP, and Advanced Polymers

High‑temperature polyimide films deliver exceptional thermal stability (>400 °C Tg), low dielectric loss, and mechanical flexibility. Liquid crystal polymers (LCP) offer ultra‑low moisture uptake and dielectric constant (<2.9), ideal for high‑frequency signal integrity. Novel fluorinated resins and hybrid epoxies further tailor CTE and loss tangent properties for demanding applications.

Lead‑Free and RoHS‑Compliant Integration

To comply with environmental regulations, substrates now utilize silver‑based surface finishes and tin‑copper alloys instead of traditional ENIG. These lead‑free chemistries maintain solderability and reliability during multiple reflow cycles, ensuring the advanced single sided substrate meets global RoHS and REACH requirements.

Embedded Components and TSVs in Single‑Sided Formats

By embedding passive components directly into dielectric layers and incorporating laser‑drilled through‑substrate vias (TSVs), manufacturers achieve vertical interconnects without additional layers. This approach preserves the simplicity of a single copper layer while boosting circuit density and reducing parasitic inductance in compact modules.

Application Areas and Industry Examples of advanced single sided substrate

Across diverse sectors, the advanced single sided substrate delivers tailored performance where reliability, size, and cost are critical:

Wearable Electronics Using Advanced Single Sided Substrate Technology

Lightweight polymers and thin copper layers enable ultra‑compact, flexible circuits for fitness trackers, smart watches, and health bands. Efficient heat spreading prevents hotspots during continuous operation, while single‑layer simplicity lowers assembly thickness and weight.

High-Speed Telecom Modules Using Advanced Single Sided Substrate

In 5G and millimeter‑wave front‑ends, signal integrity hinges on low‑loss laminates and controlled impedance. An advanced single sided substrate built on LCP or Rogers materials maintains tight dielectric tolerances, minimizing insertion loss and crosstalk in phased‑array antennas and RF transceiver modules.

Automotive Electronics Applications Using Advanced Single Sided Substrate

Under‑hood control units and powertrain sensors demand high‑temperature resistance and vibration tolerance. With polyimide dielectrics and rugged surface finishes, these substrates sustain reliable performance from –40 °C to 150 °C, meeting AEC‑Q100 standards for engine management and ADAS systems.

Medical Sensors and Implantables Using advanced single sided substrate Technology

Biocompatible laminates and thin-film metallization support disposable glucose monitors, patch‑style ECG sensors, and implantable pressure probes. The low-profile nature of the advanced single sided substrate enables minimally invasive form factors and precise signal routing in compact diagnostic devices.

Industry Examples

-

ASE leverages high‑thermal‑conductivity MCPCB designs for power LED modules.

-

Rogers Corp. offers single‑layer LCP substrates tailored for 5G front‑end modules.

-

KLA integrates laser‑drilled microvias in single‑layer boards for flip‑chip optical transceivers.

These implementations showcase how advanced single‑sided substrates bridge simplicity with cutting‑edge functionality.

Manufacturing Challenges and Solutions of advanced single sided substrate

Producing an advanced single sided substrate at scale presents several technical hurdles, each addressed through specialized processes and materials:

Precision Etching for Fine Patterns

Achieving line/space down to 50 µm requires tight control over etchant chemistry, temperature, and agitation. Advanced photoresists with high resolution and uniform coating methods (e.g., spin coating or curtain coating) ensure consistent feature definition across large panels.

Warpage and Thermal Stress Control

Single‑layer boards are prone to bow and twist during lamination and solder reflow. Use of matched CTE materials, optimized copper balance (e.g., symmetric inner tooling layers), and controlled cooling profiles minimizes dimensional distortion, preserving planarity for pick‑and‑place accuracy.

Surface Finish Options and Pad Integrity

Selecting the right finish—such as ENIG, immersion silver, or organic solderability preservatives (OSP)—depends on cost, shelf‑life, and bondability. Process controls like secondary cleaning and real‑time thickness monitoring ensure uniform deposition, preventing pad corrosion and solder joint voids.

Testing Standards for Reliability

Compliance with IPC‑6012 Class 3 and JEDEC JESD22 temperature cycling tests validates electrical integrity and mechanical strength under harsh conditions. Automated optical inspection (AOI), flying probe testing, and solderability assessments are integrated into production lines to catch defects early and guarantee long‑term performance.

Future Trends and Technological Outlook of advanced single sided substrate

Looking ahead, the advanced single sided substrate is poised to intersect with emerging packaging and sustainability initiatives:

Convergence with 2.5D Packaging and System‑in‑Substrate (SiS)

As designers seek higher interconnect density without full multilayer complexity, single‑layer boards may host silicon interposers or embedded passive networks. This hybrid approach leverages TSVs and microbumps on one side, marrying substrate simplicity with 2.5D performance.

Push Toward Sustainable Materials and Green Manufacturing

Biodegradable polymers, recycled glass fabrics, and low-VOC laminates will reduce the carbon footprint. Water‑saving etch processes and lead‑free chemistries ensure that the advanced single sided substrate meets future environmental certifications.

Integration with AIoT, EVs, and Miniaturized Edge Computing

Lightweight, thermally efficient substrates become critical in distributed sensor nodes, powertrain control units, and portable AI accelerators. Single‑layer assemblies simplify assembly while supporting high-frequency signaling.

Increased Adoption in Low‑Cost, High‑Volume Products

With optimized materials and automated production, these substrates will drive economies of scale in consumer IoT devices, large‑scale LED installations, and basic telecom endpoints, maintaining superior performance at minimal cost.