The Role of Absolics Glass Substrate in Semiconductor Packaging

In the semiconductor industry, glass substrates are emerging as a next-generation material for advanced packaging and interconnects, offering advantages over traditional materials like silicon and ceramics. With superior properties such as higher thermal conductivity, better electrical insulation, and enhanced dimensional stability, glass substrates are ideal for high-performance applications, particularly in miniaturized and complex IC designs driven by chiplet technologies. Absolics stands at the forefront of this innovation, pioneering the development and manufacturing of glass substrates that enable improved performance and scalability in semiconductor packaging. Through cutting-edge technology and strategic collaborations, Absolics has established itself as a leader in the field, making Absolics glass substrate a crucial component in the next generation of electronic devices and systems.

What is Absolics Glass Substrate?

Absolics glass substrate is a revolutionary material designed specifically for the advanced needs of the semiconductor industry. Absolics glass substrates are made from high-quality glass, offering exceptional thermal conductivity, electrical insulation, and precision. These properties make them ideal for next-gen semiconductor packaging and interconnects. Their superior thermal conductivity ensures efficient heat dissipation, while excellent electrical insulation keeps circuits stable and interference-free. Additionally, Absolics’ precise manufacturing ensures uniform thickness and surface quality, crucial for miniaturized IC designs.

When compared to traditional materials like silicon, ceramic, and BT substrates, Absolics glass substrate stands out in several areas. While silicon has been the standard in semiconductor manufacturing for years, it lacks the thermal and mechanical properties necessary for more demanding applications. Ceramic substrates offer high thermal conductivity but can be brittle and difficult to process at the required precision. BT substrates, commonly used in high-density interconnects, are often limited in their ability to manage heat and provide the necessary electrical insulation. In contrast, Absolics glass substrate combines the best of both worlds: excellent thermal management, superior insulation, and unmatched precision, making it a superior alternative for cutting-edge semiconductor technologies.

Technological Advancements by Absolics

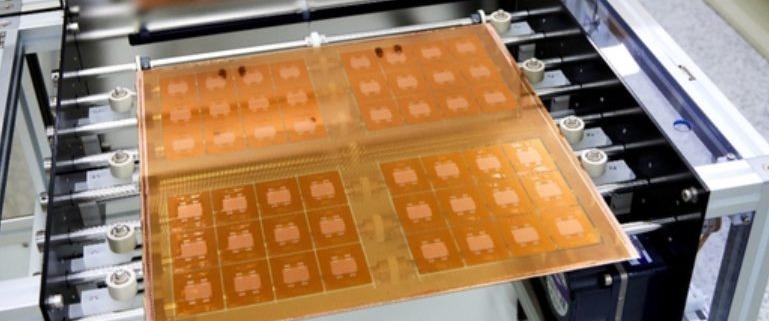

Absolics glass substrate is at the forefront of innovation in glass substrate technology, achieving significant breakthroughs in the manufacturing process. One of the primary advancements is the development of cutting-edge processing techniques that allow for the production of highly precise and uniform glass substrates. This includes advancements in thin-film deposition and surface treatment, which improve the substrate’s performance in semiconductor applications. By refining these techniques, Absolics ensures that their glass substrates can meet the stringent requirements of next-generation IC designs. Furthermore, the company’s scalability in production allows it to meet the growing demand for high-performance substrates while maintaining consistent quality, enabling large-scale manufacturing without compromising on precision.

In addition to improvements in the manufacturing process, Absolics glass substrate plays a crucial role in enabling the widespread adoption of chiplet technology. Chiplets are small, modular integrated circuits that can be combined to form larger systems, and they are a key trend in the miniaturization of semiconductors. Absolics glass substrate provides the perfect platform for these chiplets due to its high precision and excellent electrical insulation properties. As chiplet designs become increasingly complex and smaller, the need for substrates that can offer high-density interconnects and effective heat management becomes essential. Absolics glass substrate addresses these needs, supporting the scalability and integration of chiplet-based ICs in next-gen devices, making it a critical enabler for this rapidly evolving technology.

Absolics Glass Substrate’s Role in the Semiconductor Ecosystem

Absolics glass substrate is transforming the semiconductor ecosystem, enhancing performance and miniaturization of next-gen semiconductors. As demand grows for smaller, faster devices, advanced materials like Absolics glass substrate, with superior thermal conductivity, electrical insulation, and precision, are essential. Unlike traditional materials such as silicon and ceramics, it supports chiplet technology, a key trend in semiconductor miniaturization. This enables the integration of smaller, more efficient chiplets, advancing high-performance computing, mobile devices, and other emerging technologies.

In addition to its technological impact, Absolics glass substrate has formed strategic collaborations with several leading tech giants, further solidifying its position in the semiconductor industry. These partnerships focus on advancing semiconductor packaging solutions, where Absolics glass substrate is seen as a key enabler of innovation. Moreover, Absolics’ active participation in the U.S. CHIPS Act and other government initiatives underscores its commitment to strengthening the domestic semiconductor supply chain. The funding and support provided through these programs are critical for scaling up the manufacturing capabilities of Absolics glass substrate, ensuring that it can meet the growing demand for advanced materials in semiconductor production. Through these collaborations, Absolics is not only contributing to technological advancements but also shaping the future of the global semiconductor industry.

Absolics Glass Substrate in Mass Production

To meet the growing demand for Absolics glass substrate, the company is expanding its manufacturing capacity with a $600 million facility in Georgia. This state-of-the-art hub will produce high-performance glass substrates, using advanced production techniques to ensure precision, consistency, and quality at scale. Strategically located near key semiconductor hubs, the facility underscores Absolics’ commitment to supporting the U.S. semiconductor industry’s growth.

In addition to the Georgia facility, Absolics plans further expansions in Asia and Europe to meet growing international demand. These new sites will strengthen Absolics’ position as a global leader in glass substrate manufacturing, ensuring worldwide availability for semiconductor manufacturers.

As for the timeline for mass production, Absolics has set a clear path towards full-scale production. With the Georgia facility set to begin operations soon, Absolics plans to start mass production of its glass substrate in the next few years. This expansion will help meet semiconductor industry needs and support emerging trends like chiplet technology and next-gen packaging. The mass production will have a significant market impact, driving innovation in sectors such as telecommunications, automotive, and consumer electronics.

CHIPS Act and Government Support

The U.S. government has supported Absolics through the CHIPS and Science Act, awarding significant funding to boost domestic production of its glass substrates. This funding accelerates the development of critical semiconductor materials and technologies, including glass substrates, essential for next-generation packaging and interconnect solutions. It also helps Absolics scale manufacturing, establish advanced facilities, and enhance R&D to stay competitive in the semiconductor industry.

The funding from the CHIPS and Science Act will have a profound impact on Absolics glass substrate production. The funding enables Absolics to invest in new facilities, such as the $600 million plant in Georgia, ensuring U.S. competitiveness in the global semiconductor market. By supporting companies like Absolics, the government promotes growth in advanced materials crucial for innovations like chiplet-based designs. This investment strengthens the U.S. semiconductor supply chain, reduces reliance on overseas production, and creates jobs in high-tech manufacturing.

Government funding plays a crucial role in promoting semiconductor innovation, particularly in the area of glass substrates. Through programs like the CHIPS Act, the U.S. government is helping to ensure that innovative materials, such as Absolics glass substrate, are developed and produced domestically. By focusing on the advanced material needs of the semiconductor industry, the government is driving the next wave of technological advancements in electronics. This support enables companies like Absolics to continue making breakthroughs that will power future generations of electronics, from high-performance computing to next-gen mobile devices. The collaboration between private industry and government funding is setting the stage for the next era of semiconductor manufacturing, where Absolics glass substrate is poised to play a leading role.

Absolics’ Product Portfolio

Absolics offers a diverse and innovative range of glass substrates designed to meet the evolving demands of the semiconductor industry. These high-performance products are tailored for various applications, from advanced semiconductor packaging to cutting-edge interconnect technologies. Known for their precision, thermal stability, and exceptional electrical insulation properties, these substrates are ideal for high-density, high-performance integrated circuits (ICs).

The product portfolio includes different types of glass substrates, each designed for specific needs within the semiconductor ecosystem. Available in various thicknesses, surface finishes, and forms, these substrates can be customized to meet the unique requirements of each project. For instance, ultra-thin substrates are commonly used in next-generation IC packaging and chiplet integration, where minimizing space and ensuring reliable interconnects are critical. Other products are optimized for use in advanced mobile devices, high-frequency electronics, and 5G infrastructure, where superior thermal conductivity and mechanical strength are essential.

Target industries for Absolics glass substrates include telecommunications, automotive electronics, consumer electronics, and computing. As chiplet technology, high-density packaging, and miniaturization continue to grow in these sectors, the demand for these substrates increases, offering a solution to overcome the limitations of traditional materials like silicon and ceramics.

The unique selling propositions (USPs) of Absolics glass substrate set it apart from other materials used in semiconductor packaging. First, it offers superior thermal conductivity, which is crucial for efficiently dissipating heat in high-performance ICs. This makes it an ideal choice for applications like 5G devices and high-frequency systems, where heat management is essential for long-term reliability. Second, its electrical insulation properties ensure effective isolation of circuits, preventing signal interference and enhancing the overall performance of the ICs. Lastly, the high precision in manufacturing allows for high-density interconnects, which are critical for chiplet-based designs. The glass substrate offers exceptional dimensional stability and uniformity, qualities that are difficult to achieve with other materials.

Absolics glass substrate provides a versatile, high-performance solution that meets the growing demands of next-generation electronics, making it an essential component for the semiconductor industry’s future advancements.

Applications of Absolics Glass Substrate

Absolics glass substrate is playing a transformative role in advanced semiconductor packaging, particularly in chiplet-based designs. As semiconductor devices become more compact and powerful, chiplet technology is emerging as a key solution for next-generation ICs. Absolics glass substrate provides an ideal platform for chiplets due to its excellent thermal conductivity, electrical insulation, and mechanical stability. These properties allow for high-density interconnects and effective heat dissipation, ensuring reliable performance and longevity in high-performance applications.

In addition to its role in chiplet packaging, Absolics glass substrate is making significant contributions to various sectors. In consumer electronics, it is used in smartphones, tablets, and wearable devices, where space is limited and thermal management is critical. The material’s dimensional stability and strength help ensure the durability of these compact devices.

The telecommunications industry also benefits from Absolics glass substrate, particularly in the development of 5G and high-frequency components. Its ability to handle heat and provide insulation makes it ideal for RF circuits and antenna systems, enhancing the performance of telecommunications equipment.

In the automotive electronics sector, Absolics glass substrate is becoming essential for technologies in autonomous driving and electric vehicles (EVs). The material’s reliability, thermal management, and miniaturization capabilities are crucial for the development of advanced automotive systems.

Absolics glass substrate is making a significant impact in multiple industries, enabling the next generation of high-performance electronics.

Future of Absolics Glass Substrate Technology

The future of Absolics glass substrate technology is bright, with the company at the forefront of innovations in material science and processing techniques. Absolics is working on developing advanced materials that will further enhance the thermal conductivity, mechanical properties, and overall performance of its glass substrates. These improvements will be crucial as next-generation semiconductors become smaller, faster, and more powerful. The aim is to create substrates that can handle higher frequencies and more power, all while maintaining reliability and heat dissipation capabilities.

Absolics is exploring new processing methods like laser cutting and precision etching to improve production efficiency and precision. These innovations will enable the creation of thinner, more flexible substrates for emerging technologies such as flexible electronics and 3D IC packaging. Additionally, nanotechnology and advanced coating techniques are being explored to enhance glass substrate properties for use in fields like quantum computing and AI.

As demand for high-performance substrates grows, Absolics is also focused on scaling up its manufacturing capabilities. The company is investing in automated production systems and utilizing AI-driven quality control to ensure consistency and efficiency in mass production. These efforts will help meet the increasing global demand for advanced semiconductor packaging solutions.

On the global front, Absolics is expanding its reach into new markets in Asia, Europe, and Latin America, where the need for advanced materials is on the rise. In addition to expanding production facilities, such as the $600 million plant in Georgia, the company is strengthening its R&D efforts and collaborating with key players in the semiconductor supply chain. These partnerships will enable Absolics to tap into new industry sectors and continue driving the future of semiconductor technology.

Absolics is poised for continued growth and innovation. Its focus on enhancing glass substrate materials, advancing production technologies, and expanding into new global markets will ensure its leadership in the semiconductor industry for years to come.