ABF Substrate: Key to Advanced Semiconductor Packaging

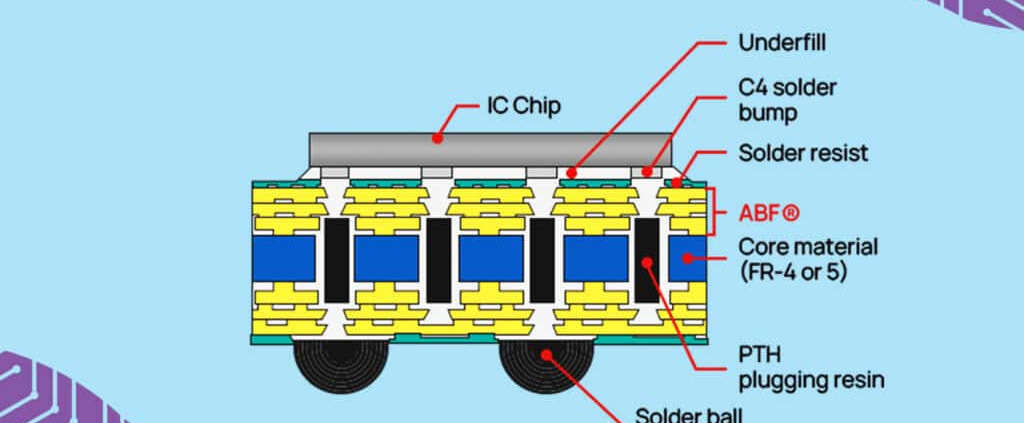

ABF Substrate, or Anisotropic Conductive Film Substrate, is a crucial component in electronic manufacturing, facilitating the interconnection of semiconductor chips and printed circuit boards. Its significance lies in providing a reliable electrical connection while accommodating the miniaturization trend in electronics. The basic structure comprises a thin film with conductive particles dispersed within, enabling electrical conductivity in specific directions. This composition ensures precise alignment and bonding during assembly processes, enhancing the performance and reliability of electronic devices. ABF substrates play a pivotal role in various applications, from consumer electronics to automotive systems, where compactness and robust connectivity are paramount.

What is ABF (Ajinomoto Build-up Film) Substrate?

ABF (Ajinomoto Build-up Film) Substrate is a type of substrate material widely used in the semiconductor packaging industry. Developed by the Ajinomoto Group, this film plays a critical role in high-density interconnect (HDI) designs for integrated circuits (ICs). Ajinomoto ABF substrates are used specifically in advanced packaging technologies such as Ball Grid Array (BGA) and Flip Chip packages, where space is limited and performance requirements are high.

In the realm of semiconductor packaging, Ajinomoto ABF substrates offer several key advantages. One of the most significant is their ability to enable higher-density interconnections. By utilizing Ajinomoto ABF material, manufacturers can achieve smaller, more compact package designs without compromising on the number of connections between the silicon chip and the printed circuit board (PCB). This is particularly important in modern electronics, where the trend toward miniaturization is driven by consumer demand for smaller, more powerful devices such as smartphones, tablets, and wearables.

Additionally, Ajinomoto ABF substrates help improve overall electrical performance by reducing signal loss and improving signal integrity. The film has a low dielectric constant, which minimizes signal delay and allows for faster data transmission between the chip and the board. Furthermore, Ajinomoto ABF substrates contribute to better power efficiency. By optimizing the interconnection pathways and minimizing resistance, Ajinomoto ABF substrates help lower the overall power consumption of the IC package, which is critical for high-performance applications like 5G infrastructure, data centers, and AI processors.

The design of ABF substrates involves a delicate balance between electrical performance, thermal management, and mechanical strength. As integrated circuits (ICs) continue to shrink in size while increasing in complexity, these factors must be carefully optimized to ensure the reliability and performance of the final package. ABF substrates, being at the core of high-density packaging, require precise design considerations to meet the growing demands of modern electronics, especially in sectors such as 5G, AI, and data centers.

Electrical Performance Considerations

One of the most critical aspects of ABF substrate design is achieving optimal signal integrity. The substrate must provide a stable platform for high-speed data transmission between the chip and the printed circuit board (PCB). Key electrical performance considerations include:

- Low dielectric constant (Dk): The Ajinomoto resin used in ABF substrates features a low dielectric constant, which helps reduce signal delay and minimizes signal loss, especially in high-frequency applications. A low Dk enables faster and more reliable signal transmission, which is crucial in applications requiring high-speed communication, such as 5G networks and advanced processors.

- Minimizing crosstalk and impedance: The design must ensure that signal traces are adequately spaced to avoid electromagnetic interference (EMI) and crosstalk between adjacent lines. Additionally, controlled impedance is essential to maintain signal integrity, particularly for high-speed circuits where variations can lead to data errors or loss of performance.

- Power distribution network (PDN): The ABF substrate’s design must also account for power delivery to the chip. An effective PDN minimizes voltage fluctuations and ensures stable power delivery to all components, which is vital for maintaining the chip’s performance under different operating conditions.

Thermal Management

As electronic components become more powerful, they generate more heat, making thermal management a crucial design factor. In ABF substrates, the ability to effectively dissipate heat ensures that the IC operates within safe temperature limits, preventing thermal-related failures. Key considerations include:

- Thermal conductivity: The materials used in ABF substrates need to exhibit good thermal conductivity to efficiently dissipate heat away from the IC. Although the Ajinomoto resin itself has moderate thermal conductivity, the substrate design can incorporate other materials or layers that enhance heat dissipation.

- Thermal via placement: Designers often include thermal vias—holes filled with conductive material—to enhance heat transfer through the layers of the substrate. Proper placement of these vias is essential for directing heat away from hotspots on the chip, such as areas with high power density.

- Thermal expansion: The substrate’s coefficient of thermal expansion (CTE) should match that of the chip to prevent mechanical stress caused by temperature changes. Mismatched CTEs can lead to warping, cracking, or delamination, which can degrade the substrate’s performance and reliability over time.

Mechanical Strength and Reliability

In addition to electrical and thermal performance, the mechanical strength of ABF substrates is a key factor that impacts the overall reliability of the package. Several mechanical properties need to be considered:

- Dimensional stability: The substrate must maintain its shape and structure during the manufacturing process and during the device’s operation. The mechanical strength of the Ajinomoto resin ensures that the substrate can withstand stresses from high-temperature processes, such as reflow soldering, without warping or deforming.

- Warpage and stress management: Warpage can occur during thermal cycling, especially in large substrates or those with complex multilayer designs. Proper material selection and layer balancing can mitigate this issue. The design must also account for mechanical stress during assembly and operation, ensuring the package remains robust under mechanical strain.

- Fatigue resistance: Over time, substrates are subjected to repeated thermal cycling and mechanical stress, leading to fatigue in the materials. ABF substrates must be designed with materials that offer high fatigue resistance to prevent cracks, delamination, or other forms of mechanical failure during the product’s lifespan.

High-Density Interconnects Supporting Miniaturization

ABF (Ajinomoto Build-up Film) substrates are pivotal in the ongoing trend toward miniaturization in electronics. The ability to support high-density interconnects is one of the key factors that enables the development of smaller, more compact electronic devices without sacrificing functionality or performance.

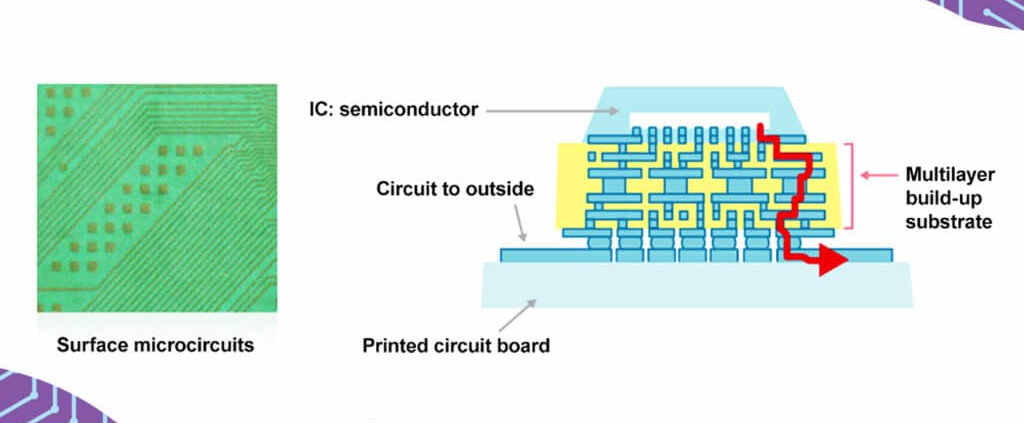

Multi-Layer Thin Film Structure

ABF substrates utilize a multi-layer thin film structure that allows for intricate and densely packed interconnections. This design approach is essential for accommodating the high integration demands of modern electronic products. The thin film layers of the ABF substrate are built up sequentially, creating a robust platform for routing numerous electrical connections in a limited space. This multi-layer capability facilitates:

- Increased Interconnect Density: The build-up film technology enables the creation of layers that include a high number of interconnections per unit area. This high-density routing is crucial for fitting more functionality into smaller packages, aligning with the miniaturization trend seen in consumer electronics such as smartphones and tablets.

- Smaller Footprints: By stacking multiple thin layers, ABF substrates can significantly reduce the overall footprint of the electronic package. This reduction in size allows for more compact designs that meet the space constraints of modern devices. Smaller footprints are particularly beneficial for portable electronics, where conserving space is essential to maintain slim and lightweight profiles.

- Enhanced Integration: The ability to incorporate a high number of interconnections within a confined space also supports the integration of additional features and functionalities into a single package. This is particularly advantageous in high-performance applications where integrating multiple components, such as power management, memory, and processing units, into a compact space is required.

Adapting to Modern Electronics Needs

The miniaturization of electronic products is driven by several factors, including consumer demand for more portable devices and advancements in technology that require denser circuitry. ABF substrates address these needs by offering several benefits:

- Flexibility in Design: The multi-layer nature of ABF substrates allows for greater design flexibility. Engineers can create complex circuit layouts with high precision, optimizing the use of available space and supporting the development of innovative, compact designs.

- Improved Performance: By facilitating high-density interconnections, ABF substrates contribute to improved overall performance of electronic devices. Faster data transfer and reduced signal loss are achieved through the low dielectric constant of the material, which is crucial for maintaining the performance of high-speed and high-frequency applications.

- Reduced Package Size: The use of ABF substrates directly leads to a reduction in the size of the IC package. This is particularly valuable in consumer electronics where space constraints are a significant consideration. Smaller packages not only make devices more compact but also enable more efficient use of space within the device itself.

ABF Substrate’s Technical Features

ABF (Ajinomoto Build-up Film) substrates are at the forefront of high-performance packaging technology, offering several technical features that make them ideal for advanced semiconductor applications. These features include exceptional signal integrity, a low dielectric constant, and high thermal management capabilities. Together, they support the development of cutting-edge electronic devices and systems.

Core of High-Performance Packaging Technology

Exceptional Signal Integrity

One of the standout characteristics of ABF substrates is their ability to maintain exceptional signal integrity. This is crucial for high-speed and high-frequency applications, where even minor disruptions can lead to significant performance issues. The low dielectric loss of ABF substrates ensures minimal signal attenuation and reduced noise interference. This capability is particularly important for applications such as:

- High-Speed Data Transmission: The low dielectric constant of ABF substrates helps in minimizing signal delay, allowing for faster and more reliable data transfer. This is essential for modern applications such as 5G networks, advanced computing, and high-resolution imaging systems.

- High-Frequency Circuits: The superior electrical properties of ABF substrates support the reliable operation of high-frequency circuits, where signal integrity is paramount. This makes them ideal for RF (radio frequency) and microwave applications, where maintaining signal quality is critical for performance.

Low Dielectric Constant

The low dielectric constant of ABF substrates is a key factor that enhances their performance in electronic packaging. Dielectric constant (Dk) is a measure of a material’s ability to store electrical energy in an electric field. A lower Dk value indicates that the material has less capacitance between conductors, leading to several benefits:

- Reduced Signal Delay: A lower dielectric constant helps reduce the propagation delay of electrical signals, resulting in faster data transmission speeds. This is crucial for applications requiring high-speed data processing and communication.

- Minimized Signal Loss: With a low Dk, ABF substrates experience less signal loss due to lower dielectric loss. This improves overall signal integrity and ensures that high-frequency signals are transmitted with greater accuracy.

- Enhanced Performance in Dense Designs: The low dielectric constant allows for tighter spacing of signal traces and smaller features on the substrate, supporting high-density interconnect designs without compromising electrical performance.

High Thermal Management Capabilities

Effective thermal management is another critical feature of ABF substrates. As electronic components become more powerful, managing heat dissipation becomes increasingly important to maintain device reliability and performance. ABF substrates contribute to thermal management in several ways:

- Good Thermal Conductivity: ABF substrates have good thermal conductivity properties, which help dissipate heat generated by high-density interconnections and active components. This is essential for preventing overheating and ensuring the stable operation of the IC.

- Dimensional Stability: The thermal stability of ABF substrates ensures that the material maintains its shape and structural integrity during thermal cycling. This helps prevent issues such as warping or delamination, which can impact the performance and reliability of the electronic package.

- Effective Heat Dissipation: The design and materials used in ABF substrates support efficient heat dissipation from the chip to the PCB, reducing the risk of thermal buildup and extending the lifespan of the device.

In the realm of semiconductor packaging, BT (Bismaleimide Triazine) substrates and ABF (Ajinomoto Build-up Film) substrates represent two distinct technologies that cater to different needs in high-density interconnect (HDI) designs. Both materials play crucial roles in advanced packaging, but they differ significantly in their properties, performance, and applications.

Material Composition and Properties

- BT Substrate: BT substrates are made from a resin system that combines bismaleimide and triazine, offering a robust material suitable for high-density interconnections. The BT resin is known for its excellent thermal stability, high glass transition temperature (Tg), and mechanical strength. These properties make it a reliable choice for applications requiring durability under thermal and mechanical stress. BT substrates typically have a moderate dielectric constant, which is suitable for many high-speed applications but may not be as low as that of ABF substrates.

- ABF Substrate: ABF substrates utilize Ajinomoto Build-up Film, a proprietary resin with a low dielectric constant (Dk) and low dielectric loss. This film is renowned for its exceptional electrical performance, making it ideal for high-speed and high-frequency applications. ABF materials also offer good thermal stability and dimensional stability, which are crucial for maintaining performance in demanding environments. The low Dk of ABF substrates helps reduce signal loss and improve signal integrity, which is essential for modern high-performance IC packages.

Electrical Performance

- BT Substrate: BT substrates provide adequate electrical performance for many applications, but they may exhibit higher signal loss and delay compared to ABF substrates due to their relatively higher dielectric constant. While BT substrates are effective for many high-density interconnect designs, they might not meet the stringent requirements of next-generation high-speed applications, where signal integrity and speed are critical.

- ABF Substrate: ABF substrates excel in electrical performance due to their low dielectric constant and loss. This makes them particularly well-suited for high-speed data transmission and high-frequency applications. The low Dk of ABF substrates helps minimize signal degradation and crosstalk, enabling faster and more reliable data transfer. This is crucial for applications such as 5G communication, advanced computing, and high-resolution displays.

Thermal Management

- BT Substrate: BT substrates offer good thermal performance due to their high Tg and thermal stability. This allows them to withstand the heat generated during high-power operation and soldering processes. However, they may not be as effective in heat dissipation as ABF substrates, particularly in applications with extreme thermal demands.

- ABF Substrate: ABF substrates also exhibit strong thermal management properties, with good heat resistance and thermal stability. The low thermal expansion coefficient and high thermal conductivity of ABF materials help in effective heat dissipation, preventing overheating and ensuring the reliability of high-performance ICs. This capability is particularly beneficial for high-power and high-density electronic applications.

Manufacturing Process and Cost

- BT Substrate: The manufacturing process for BT substrates involves advanced lamination techniques and high-temperature curing, which can be complex and costly. The process requires precise control to achieve the desired material properties and performance. While BT substrates are well-established and widely used, their production can be expensive, particularly for large volumes or complex designs.

- ABF Substrate: ABF substrates are produced using a build-up film technology, which allows for a more flexible and scalable manufacturing process. The build-up layers are deposited sequentially, enabling fine-pitch and high-density interconnections. Although the initial cost of ABF materials can be high, their ability to support complex and high-density designs can offset the costs through improved performance and reduced size.

Applications and Suitability

- BT Substrate: BT substrates are commonly used in a range of applications, including consumer electronics, automotive, and telecommunications. They are suitable for many high-density interconnect designs but may not be the best choice for the most demanding high-speed and high-frequency applications.

- ABF Substrate: ABF substrates are ideally suited for applications requiring high-speed data transfer, high-frequency performance, and compact designs. They are commonly used in advanced computing, 5G infrastructure, and high-resolution displays, where their superior electrical performance and signal integrity are essential.

1.ALCANTAPCB Shenzhen Co., Ltd.

- Overview:ALCANTA (Shenzhen) specializes in manufacturing high-performance packaging substrates, offering products ranging from 2-layer to 26-layer designs. The company serves various industries, including high-performance computing, consumer electronics, and automotive electronics. With advanced microfabrication capabilities, ALCANTA ensures high-density and high-precision circuit designs.

- Key Products:ABF packaging substrates,High-density interconnect (HDI) packaging substrates,Automotive-grade packaging substrates,Glass-core FCBGA substrates (4 to 20 layers)

- Capabilities: ALCANTA supports a minimum trace/spacing of 9μm and a minimum laser via hole size of 55μm. The company utilizes industry-leading materials, primarily sourced from Japan, including Mitsubishi’s BT series (e.g., L-832NX, HL832NX), Showa Denko materials (e.g., MCL-E705G, MCL-E-770G, MCL-E-700G, MCL-E-795G), and Ajinomoto materials (e.g., GX92R, GXT31R2, GZ41R2H, GL102R8HF, GL103R8H). Additionally, ALCANTA produces high-precision HDI PCBs with trace/spacing as small as 15μm and offers glass-core FCBGA substrates with superior flatness. The company provides a wide range of advanced materials and customization options to meet specific customer requirements.

2. Ajinomoto Fine-Techno Co., Inc.

- Overview: Ajinomoto Fine-Techno is a subsidiary of the Ajinomoto Group and the original developer of the ABF technology. They are the primary producer of Ajinomoto Build-up Film (ABF) and hold a significant share of the global market.

- Key Products: ABF-LF-1200, ABF-2018, ABF-2110

- Capabilities: Ajinomoto Fine-Techno offers a range of ABF products designed to meet various needs in semiconductor packaging, including high-density interconnects and high-performance applications. Their products are known for superior signal integrity, low dielectric constant, and high thermal stability.

3. Shinko Electric Industries Co., Ltd.

- Overview: Shinko Electric Industries is a major player in the semiconductor packaging industry and a significant supplier of ABF substrates. They are known for their advanced manufacturing capabilities and comprehensive product portfolio.

- Key Products: Shinko’s ABF substrates are designed for high-density and high-performance applications, including advanced IC packages and mobile devices.

- Capabilities: Shinko Electric provides high-quality ABF substrates with a focus on innovation and efficiency. Their products are used in various applications, from consumer electronics to automotive and telecommunications.

4. Samsung Electro-Mechanics Co., Ltd.

- Overview: Samsung Electro-Mechanics, part of the Samsung Group, is a leading supplier of electronic components, including ABF substrates. They leverage their extensive R&D and manufacturing resources to provide advanced substrate solutions.

- Key Products: Samsung’s ABF substrates support high-speed data transmission and high-frequency applications, catering to the latest demands in semiconductor packaging.

- Capabilities: Samsung Electro-Mechanics is known for its technological advancements and large-scale production capabilities, enabling them to meet the growing global demand for high-performance ABF substrates.

5. Unimicron Technology Corporation

- Overview: Unimicron Technology is a well-established manufacturer of PCB and semiconductor packaging materials, including ABF substrates. They are recognized for their comprehensive product offerings and global reach.

- Key Products: Unimicron provides a variety of ABF substrates suitable for different packaging needs, including high-density and high-performance applications.

- Capabilities: The company’s advanced manufacturing processes and quality control systems ensure that their ABF substrates meet rigorous industry standards.

6. Ibiden Co., Ltd.

- Overview: Ibiden is a leading Japanese manufacturer specializing in electronic materials, including ABF substrates. They are known for their innovation and high-quality products in the semiconductor packaging sector.

- Key Products: Ibiden’s ABF substrates are designed for high-density interconnects and advanced semiconductor packages, offering excellent performance and reliability.

- Capabilities: Ibiden leverages its expertise in materials science and manufacturing technology to produce ABF substrates that support cutting-edge applications in various industries.

7. Kyocera Corporation

- Overview: Kyocera is a global technology company that manufactures a wide range of electronic components, including ABF substrates. They are known for their high-quality products and advanced technology.

- Key Products: Kyocera’s ABF substrates cater to high-performance and high-density packaging needs, with a focus on reliability and precision.

- Capabilities: Kyocera combines its extensive experience in electronics with advanced manufacturing techniques to deliver high-performance ABF substrates for diverse applications.

Get a Quote Now

FAQS ABOUT ABF Substrate

What is ABF substrate?

ABF substrate, or Anisotropic Conductive Film substrate, is a vital component used in electronics manufacturing for creating electrical connections between semiconductor chips and printed circuit boards. It consists of a thin film with conductive particles dispersed within, allowing for precise alignment and bonding during assembly processes.

What is the difference between BT and ABF substrate?

The main difference between BT (Bismaleimide Triazine) and ABF substrates lies in their composition and characteristics. ABF substrates utilize a thin film with conductive particles, enabling fine-pitch interconnections and flexibility. On the other hand, BT substrates feature a thermosetting resin matrix reinforced with glass fibers, offering superior mechanical strength and thermal stability, but may have limitations in fine-pitch interconnections.

Who manufactures ABF substrates?

Several companies manufacture ABF substrates, including Ibiden, Shinko Electric Industries, and Daeduck Electronics, among others.

Why is there a shortage of ABF substrate?

A shortage of ABF substrates can occur due to various factors. Increased demand from industries like consumer electronics, automotive, and telecommunications can strain production capacities. Disruptions in the global supply chain, such as natural disasters or geopolitical tensions, may lead to delays in raw material procurement and manufacturing processes. Additionally, technological advancements requiring specialized materials and processes may contribute to shortages by limiting the availability of ABF substrates.