Ceramic substrates are essential components in electronic and industrial fields, providing a stable base for electronic circuits and components. These thin, rigid, and insulating materials offer excellent thermal conductivity and electrical insulation, ensuring reliability and high performance in various applications such as Printed Circuit Boards (PCBs), semiconductors, aquarium and dental equipment, crowns, catalytic converters, and more. Their versatility and ability to withstand high temperatures make ceramic substrates indispensable across diverse technological realms.

What is a Ceramic Substrate?

Ceramic substrates are rigid, thermally stable, and electrically insulating materials used as a base for electronic circuitry. Compared to traditional substrates such as FR4 or polyimide, ceramics offer:

- Superior thermal conductivity (up to 200 W/m·K for AlN)

- Excellent electrical insulation at high voltages

- High mechanical strength and dimensional stability

- Better reliability in harsh environments

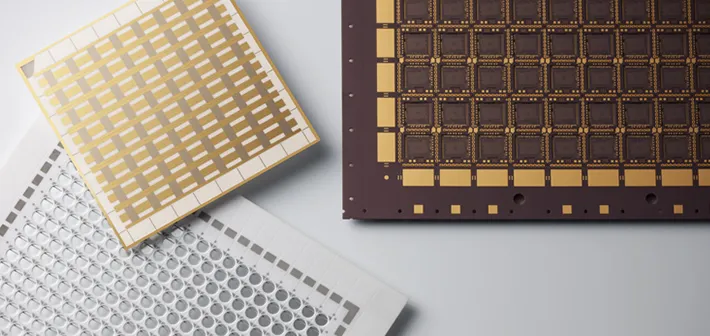

Common Materials:

- Alumina (Al₂O₃): Cost-effective, moderate thermal conductivity

- Aluminum Nitride (AlN): High thermal conductivity, suitable for power electronics

- Silicon Nitride (Si₃N₄): High toughness, excellent thermal shock resistance

High-Frequency and High-Power Electronics

Ceramic substrates excel in RF circuits and power modules due to their low dielectric loss and efficient heat dissipation.

Automotive, Aerospace, and Industrial Control

Used in EV inverters, ECU systems, and industrial automation due to their resistance to thermal stress and vibration.

LED Lighting and Power Modules

Enable better heat management in compact, high-brightness LED arrays and power switching circuits.

RF and Microwave Circuits

Support stable, high-frequency performance with precise impedance control and minimal signal loss.

Ceramic Substrate Manufacturing Process

Raw Material Selection

High-purity ceramic powders (Al₂O₃, AlN, Si₃N₄) are chosen based on thermal and mechanical requirements.

Green Tape Casting or Dry Pressing

Ceramic slurries are cast into tapes or dry-pressed into sheets to form the base structure.

Laser Drilling or Punching of Vias

Precise via holes are created to enable vertical interconnects.

Metallization (DPC, HTCC, LTCC, AMB)

| Process | Description |

|---|---|

| DPC | Direct copper plating on ceramic |

| HTCC | Co-fired ceramic with refractory metals at ~1600°C |

| LTCC | Co-fired at <900°C, supports embedded passives |

| AMB | Brazed copper bonded to ceramic for power modules |

Firing/Sintering and Surface Finishing

Ceramic substrates are sintered to full density and polished or plated for component assembly.

Quality Control and Electrical Testing

Dimensional, electrical, and thermal testing ensures reliability for demanding applications.

| Type | Key Features | Pros | Cons | Applications |

| HTCC | High-temp co-firing with refractory metals | Hermetic, durable | Limited RF performance | Sensors, aerospace |

| LTCC | Low-temp co-firing with glass-ceramic | RF capable, multilayer | Lower thermal performance | Wireless, radar |

| DPC | Direct plating of copper | High resolution | Complex process | RF modules |

| DBC | Direct bonded copper on ceramic | High current, thermal cycling | Coarse resolution | Power modules, LEDs |

Ceramic Substrate vs Traditional PCB Substrates

| Property | Ceramic Substrates | FR4 / Polyimide |

| Thermal Conductivity | High (up to 200 W/m·K) | Low (<1 W/m·K) |

| Electrical Insulation | Excellent | Good |

| Mechanical Strength | High rigidity, durable | Less robust |

| Reliability | Ideal for harsh environments | Prone to thermal failure |

| Cost | Higher initial cost | Lower upfront cost |

Key Considerations

- Material quality: High-purity ceramics for consistent performance

- Manufacturing capability: Full process coverage (DPC, HTCC, LTCC, DBC)

- Tolerance control: Precision in dimensions, via size, and conductor layout

- Customization: Flexible support for special shapes, stack-ups, and prototypes

Questions to Ask Suppliers

- What ceramic materials do you offer? What are their properties?

- What is your minimum trace/space capability?

- Do you support quick-turn prototyping?

- What testing and QC measures are in place?

Certifications and Standards

- ISO 9001 / IATF 16949: Quality assurance

- RoHS / REACH: Environmental compliance

- UL / IPC Standards: Safety and performance reliability

ALCANTAPCB Capabilities in Ceramic Substrate Manufacturing

In-house Processes & Quality Control

ALCANTAPCB runs end-to-end ceramic PCB production with strict QC, from material preparation to metallization and final inspection.

Material Options

Supports Al₂O₃, AlN, and Si₃N₄ substrates for diverse performance needs.

Custom Design Support and Prototyping

Fast response for custom layouts, multi-layer builds, and DFM guidance.

Global Delivery and Technical Support

Rapid worldwide shipping with multilingual technical assistance.

Ready to Elevate Your Circuit Design with Ceramic Substrates?

Whether you’re building high-power modules, RF systems, or automotive control units, ALCANTAPCB delivers reliable, high-performance ceramic substrate PCBs tailored to your needs.

FAQs About Ceramic Substrate

What is a ceramic substrate?

A ceramic substrate is a type of electronic substrate made from ceramic materials, such as alumina (Al₂O₃), aluminum nitride (AlN), or beryllium oxide (BeO). These substrates provide a stable, heat-resistant, and insulating foundation for mounting electronic components, and they are commonly used in high-frequency, high-power, and high-temperature applications due to their excellent thermal and electrical properties.

How thick is a ceramic substrate?

The thickness of a ceramic substrate can vary depending on the specific application and requirements. Generally, ceramic substrates range in thickness from 0.25 mm to 1.5 mm. However, they can be made thinner or thicker based on the needs of the particular device or circuit they are used in.

What are the ceramics in electronic substrate packages?

Common ceramics used in electronic substrate packages include:

- Alumina (Al₂O₃): The most widely used ceramic material due to its good thermal conductivity, mechanical strength, and electrical insulation properties.

- Aluminum Nitride (AlN): Known for its excellent thermal conductivity and electrical insulation, making it ideal for high-power applications.

- Beryllium Oxide (BeO): Offers superior thermal conductivity but is less commonly used due to its toxicity and handling concerns.

- Silicon Nitride (Si₃N₄): Provides high strength and thermal stability, often used in more demanding applications.

What are the materials used in ceramic packaging?

Ceramic packaging typically involves the use of several key materials:

- Ceramic Substrates: As mentioned, materials like alumina, aluminum nitride, beryllium oxide, and silicon nitride are common.

- Metallization: Conductive materials such as tungsten (W), molybdenum (Mo), or copper (Cu) are used for creating conductive paths on the ceramic substrate.

- Seals and Caps: Materials like kovar (an alloy of iron, nickel, and cobalt) or other metal alloys are often used for creating hermetic seals and protective caps for the ceramic packages.

- Glass or Ceramic Frit: Used as sealing materials to ensure hermeticity in the package.

- Bonding Wires: Gold (Au), aluminum (Al), or copper (Cu) wires are used to connect the chip to the package leads.