Understanding the Benefits of China Rogers PCB Manufacturing

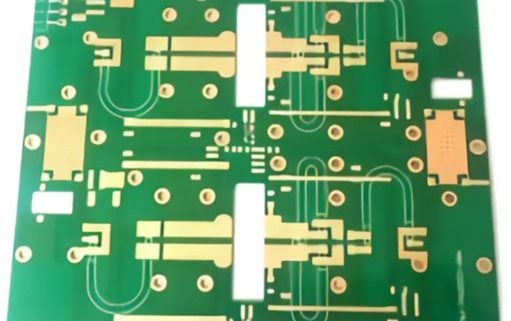

Rogers PCB is a high-performance printed circuit board known for its superior electrical properties and thermal stability, particularly suited for high-frequency applications. With low dielectric loss and excellent thermal conductivity, Rogers PCBs are widely used in wireless communication, radar, and satellite technology. In these demanding environments, Rogers PCBs ensure signal integrity and system reliability, making the choice of the right manufacturer crucial.

In China, many reputable manufacturers focus on producing high-quality Rogers PCBs. Sourcing Rogers PCBs from reputable manufacturers in China ensures that customers can obtain superior products at competitive prices. These manufacturers not only possess advanced production equipment but also provide reliable quality control to meet various application needs. Therefore, understanding and selecting the right china rogers pcb manufacturers is essential for the successful implementation of high-frequency circuits.

What is Rogers PCB?

Rogers PCB is a high-performance printed circuit board that stands out in high-frequency applications due to its exceptional electrical performance and thermal stability. The core of Rogers PCB lies in its use of specialized materials, such as RO4350B and RO4003C, which excel in electrical insulation, heat resistance, and mechanical strength. These properties make Rogers PCBs particularly suitable for applications in wireless communication, radar systems, and satellite communications, effectively transmitting high-frequency signals while minimizing signal loss.

Comparison with Other PCB Types

Compared to traditional FR-4 PCBs, Rogers PCBs offer significant advantages. FR-4 is a common PCB material suitable for low-frequency applications, but it often fails to meet requirements in high-frequency environments due to higher dielectric loss and thermal instability. In contrast, Rogers materials provide lower dielectric constants and losses in high-frequency circuits, ensuring signal integrity and reliability.

In China, many manufacturers specialize in producing high-quality china rogers pcb, leveraging advanced production technologies and stringent quality control to ensure that each circuit board meets industry standards. By choosing these specialized manufacturers, customers can acquire high-performance Rogers PCBs that fulfill their high-frequency application needs.

Key Features of Rogers PCB

Rogers PCB is renowned for its unique properties that make it particularly suitable for high-frequency and microwave applications. Here are some of the key features that set Rogers PCBs apart from traditional PCB materials:

Low Dielectric Loss and High Thermal Stability

One of the most significant advantages of Rogers PCB is its low dielectric loss. This property is crucial in high-frequency applications where signal integrity is paramount. Low dielectric loss minimizes signal degradation, allowing for clearer and more reliable transmission of high-frequency signals. Additionally, Rogers materials exhibit high thermal stability, which means they can withstand elevated temperatures without losing performance. This characteristic is essential in applications where thermal management is a concern, ensuring that the PCB maintains its electrical properties even under challenging conditions.

Advantages for High-Frequency and Microwave Applications

Rogers PCBs are specifically designed to perform well in high-frequency and microwave applications. Their unique material composition allows for lower dielectric constants, which reduce signal delay and improve bandwidth. This makes Rogers PCBs ideal for RF (radio frequency) and microwave circuits, where precision and performance are critical. The ability to maintain low signal loss over extended frequency ranges gives designers the confidence to develop advanced communication systems, radar technologies, and satellite communications that demand high reliability.

Common Applications Across Various Industries

Rogers PCBs find extensive use across a variety of industries due to their outstanding performance characteristics. Some common applications include:

- Telecommunications: Rogers PCBs are widely used in base stations, antennas, and other components in wireless communication systems, where signal integrity is crucial.

- Aerospace and Defense: In radar and electronic warfare systems, the reliability and performance of Rogers PCBs are essential for mission-critical applications.

- Medical Devices: High-frequency applications in medical imaging equipment, such as MRI and ultrasound machines, benefit from the low loss and high stability of Rogers materials.

- Consumer Electronics: Many high-end consumer devices, such as smartphones and tablets, utilize Rogers PCBs for their RF components, ensuring better connectivity and performance.

The key features of Rogers PCB, including low dielectric loss, high thermal stability, and suitability for high-frequency applications, make it a preferred choice for a wide range of industries. Its application versatility demonstrates its importance in advancing modern technology.

Difference Between Rogers PCB and FR-4

When comparing Rogers PCB to FR-4, several key differences in material composition, performance, and cost considerations highlight why Rogers PCBs are often preferred for high-frequency applications.

Material Composition and Properties

Rogers PCBs are made from specialized materials such as RO4350B, RO4003C, and RO3010, which are designed specifically for high-frequency applications. These materials feature lower dielectric constants and lower loss tangents, providing excellent electrical insulation and heat resistance. In contrast, FR-4 is a fiberglass-reinforced epoxy laminate, widely used for standard PCBs. While FR-4 offers decent performance for low-frequency applications, its dielectric constant is higher, leading to increased signal loss at higher frequencies.

Performance Differences in High-Frequency Applications

In high-frequency applications, the performance differences between Rogers PCB and FR-4 become evident. Rogers materials are engineered to handle RF signals effectively, offering superior dielectric stability, lower signal loss, and improved thermal conductivity. This makes Rogers PCBs ideal for telecommunications, microwave circuits, and radar systems, where maintaining signal integrity is crucial. Conversely, FR-4 is less suitable for high-frequency applications due to its higher dielectric loss and potential for signal distortion, which can lead to degraded performance in advanced electronic systems.

Cost Considerations and Applications for Each Type

Cost is a significant factor when choosing between Rogers PCB and FR-4. FR-4 is generally more affordable and widely available, making it a popular choice for cost-sensitive applications and consumer electronics where high-frequency performance is not a priority. On the other hand, Rogers PCBs, while more expensive, offer superior performance in specialized applications. Their high cost can be justified in sectors like aerospace, defense, and telecommunications, where reliability and performance are paramount.

While FR-4 remains a go-to material for many standard applications due to its lower cost, Rogers PCBs excel in high-frequency environments, offering enhanced electrical properties and performance. The choice between the two ultimately depends on the specific requirements of the application and the importance of signal integrity and reliability.

Leading Rogers PCB Manufacturers in China

China is home to numerous reputable manufacturers specializing in Rogers PCBs, known for their advanced technology and competitive pricing. Below is an overview of some notable manufacturers, highlighting their services, capabilities, and quality assurance practices.

ALANTAPCB

ALCANTAPCB is one of the leading Rogers PCB manufacturers in China, specializing in high-frequency and microwave circuit boards. The company has extensive experience and advanced production facilities, enabling it to produce a variety of complex, high-performance PCBs using Rogers materials. ALCANTAPCB employs cutting-edge processing technology to ensure high quality and precision in Rogers PCBs, making them ideal for applications such as RF (radio frequency), microwave communications, and radar systems. In addition to fast production and delivery capabilities, the company offers customized services to meet specific electrical performance and size requirements. Through a strict quality management system, ALCANTAPCB guarantees high reliability and consistency in each PCB, establishing itself as a trusted supplier in the Rogers PCB industry.

RFPCB

RFPCB is recognized for its expertise in high-frequency PCB production, focusing on Rogers materials. They offer a range of services, including custom PCB design, fabrication, and assembly. With a strong emphasis on quality control, RFPCB uses automated testing equipment to ensure that each PCB meets stringent industry standards. Their commitment to customer service and fast turnaround times makes them a popular choice for clients needing reliable solutions.

Viasion

Viasion has established itself as a leading manufacturer of high-performance PCBs, including Rogers PCBs. They provide a comprehensive range of services, from PCB prototyping to mass production. Viasion is known for its advanced manufacturing processes, which include laser drilling and precision etching, ensuring high-quality products. They also prioritize quality assurance, utilizing both in-house testing and third-party audits to maintain high standards.

Andwin PCB

Andwin PCB specializes in providing high-frequency and microwave PCBs using Rogers materials. Their capabilities include multilayer PCB fabrication and custom design services. Andwin PCB places a strong emphasis on research and development, continually enhancing their manufacturing processes. They implement strict quality control measures, including IPC certification and compliance with international standards, to guarantee product reliability.

RayPCB

RayPCB offers a wide range of PCB solutions, including Rogers PCBs for high-frequency applications. They provide comprehensive services from design to assembly, catering to various industries such as telecommunications and medical devices. RayPCB is committed to quality assurance, using state-of-the-art equipment for testing and inspection. Their focus on customer satisfaction and flexibility in production schedules has earned them a strong reputation in the market.

FLJ PCB

FLJ PCB focuses on the production of high-quality Rogers PCBs and is known for its competitive pricing and quick lead times. They offer various services, including rapid prototyping and low-volume production, making them suitable for startups and smaller companies. FLJ PCB employs rigorous quality control processes, including automated optical inspection (AOI) and functional testing, to ensure the reliability of their products.

Other Manufacturers

In addition to the above manufacturers, many other companies listed on PCB Directory also provide Rogers PCB solutions. These manufacturers vary in size and specialization, offering a range of services that cater to different industry needs. Some may focus on niche markets, while others provide comprehensive solutions for mass production.

Dielectric Constant of Rogers PCB Material

The dielectric constant (Dk) is a critical parameter in PCB applications, particularly for high-frequency circuits. It measures a material’s ability to store electrical energy in an electric field, which directly affects signal propagation speed and signal integrity. A lower dielectric constant typically results in lower signal loss and faster signal transmission, making it essential for high-performance PCBs used in telecommunications, radar, and microwave applications.

Significance of Dielectric Constant in PCB Applications

In PCB design, the dielectric constant influences various factors, including impedance, capacitance, and overall signal integrity. For high-frequency applications, maintaining a consistent dielectric constant across the PCB is crucial, as fluctuations can lead to signal distortion and performance degradation. A material with a stable dielectric constant ensures that signals travel through the PCB consistently, allowing for reliable communication in advanced electronic systems.

Specific Values for Various Rogers Materials

Different Rogers materials exhibit varying dielectric constants, tailored for specific applications. Here are some commonly used Rogers materials and their dielectric constants:

- RO4350B: This material has a dielectric constant of approximately 3.48, making it ideal for high-frequency applications. Its low loss tangent contributes to minimal signal degradation, enhancing performance in RF and microwave circuits.

- RO4003C: With a dielectric constant of around 3.38, RO4003C is another popular choice for high-frequency applications. It provides excellent thermal stability and electrical performance, making it suitable for a range of telecommunications and aerospace applications.

- RO3010: This material has a dielectric constant of approximately 3.0, offering even lower signal loss for applications requiring high-speed transmission. Its properties make it suitable for advanced RF applications and high-frequency circuits.

Implications for Performance in High-Frequency Circuits

The dielectric constant of Rogers materials has significant implications for performance in high-frequency circuits. Lower dielectric constants reduce the delay in signal propagation, allowing for higher data rates and improved bandwidth. Additionally, materials with stable dielectric constants minimize variations in impedance, which is critical for maintaining signal integrity and preventing reflections that can disrupt communication.

The dielectric constant is a vital factor in the performance of Rogers PCBs, influencing signal integrity and overall circuit performance. With specific values that cater to various high-frequency applications, Rogers materials like RO4350B, RO4003C, and RO3010 provide designers with the flexibility to select the most suitable material for their specific needs, ensuring optimal performance in advanced electronic systems.

Why Choose China for Rogers PCB Manufacturing?

Choosing China as a destination for Rogers PCB manufacturing offers several advantages that appeal to businesses looking for high-quality solutions at competitive prices. Here are some key reasons why manufacturing in China is a strategic choice for Rogers PCBs.

Advantages of Manufacturing in China

One of the most compelling reasons to manufacture Rogers PCBs in China is cost efficiency. The country benefits from lower labor costs compared to many Western nations, which translates into reduced production expenses. This cost advantage allows manufacturers to offer competitive pricing without compromising quality. Additionally, China’s well-established supply chain and logistics infrastructure facilitate timely delivery of materials and products, further enhancing cost efficiency.

China also boasts advanced production capabilities, including state-of-the-art machinery and technology for PCB fabrication. Many Chinese manufacturers have invested heavily in research and development, enabling them to produce high-performance Rogers PCBs that meet the demanding specifications of various industries. This combination of cost efficiency and advanced technology makes China an attractive option for companies seeking to produce high-quality PCBs.

Access to a Wide Range of Manufacturers

The Chinese market features a diverse array of manufacturers specializing in Rogers PCBs. This variety allows businesses to choose from numerous options, enabling them to find a manufacturer that aligns with their specific needs and requirements. Whether a company needs high-volume production or specialized custom designs, there are manufacturers in China equipped to handle various demands. The availability of multiple suppliers also fosters competition, which can lead to better pricing and services for clients.

Quality Control and Certifications

When selecting a manufacturer in China, quality control is paramount. Reputable manufacturers implement rigorous quality assurance practices to ensure that their products meet industry standards. It’s essential to look for certifications such as ISO 9001, IPC standards, and RoHS compliance, which indicate that the manufacturer adheres to recognized quality management systems and environmental regulations.

Many Chinese manufacturers utilize advanced testing techniques, including automated optical inspection (AOI) and X-ray inspection, to guarantee that each PCB meets the required specifications. Engaging with manufacturers that prioritize quality control and possess the necessary certifications can help ensure that the Rogers PCBs produced are reliable and perform optimally in high-frequency applications.

Choosing China for Rogers PCB manufacturing presents several advantages, including cost efficiency, access to a wide range of specialized manufacturers, and robust quality control practices. By carefully selecting a reputable manufacturer that adheres to quality standards, businesses can leverage these benefits to achieve high-performance Rogers PCBs that meet the demands of their specific applications. This strategic choice not only enhances product quality but also contributes to overall business success in competitive markets.

FQAs Abut China Rogers PCB

Notable PCB manufacturers from China include RFPCB, Viasion, Andwin PCB, RayPCB, and FLJ PCB, among others. These companies specialize in high-quality PCB production, including Rogers PCBs.

Rogers PCBs are made from specialized materials designed for high-frequency applications, featuring lower dielectric constants and loss tangents compared to FR-4. While FR-4 is suitable for standard, low-frequency applications, it has higher dielectric loss and is less stable at high frequencies, making Rogers PCBs preferable for telecommunications and microwave circuits.

Rogers PCB refers to a type of high-performance printed circuit board made from Rogers materials, known for their excellent electrical properties, thermal stability, and low dielectric loss. These characteristics make them ideal for high-frequency applications in telecommunications, radar, and satellite technologies.

The dielectric constant of Rogers PCB materials varies by specific type. For example, RO4350B has a dielectric constant of approximately 3.48, while RO4003C is around 3.38. These lower dielectric constants contribute to reduced signal loss and improved performance in high-frequency applications.