The Importance of Rogers PCB Laminates in Modern Electronics

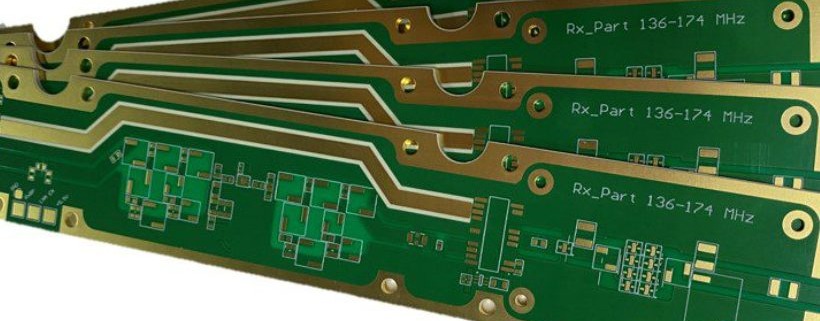

Rogers PCB laminates play a crucial role in the electronics industry, especially in applications that require high-performance and reliability. These laminates are designed to deliver excellent electrical properties, thermal stability, and minimal signal loss, making them ideal for high-frequency circuits used in telecommunications, aerospace, and medical devices. As the demand for advanced electronic systems continues to grow, the importance of Rogers PCB laminates becomes increasingly evident, as they support the development of innovative technologies.

Rogers Corporation, a leader in the PCB materials field, has established a strong reputation for manufacturing high-quality laminates that meet the evolving needs of engineers and designers. With a commitment to research and development, Rogers consistently advances its product offerings, ensuring that their laminates remain at the forefront of technology. By providing solutions that enhance performance and reliability, Rogers Corporation plays a pivotal role in shaping the future of electronic devices through its superior rogers pcb laminates.

What is Rogers PCB Material?

Rogers PCB materials, particularly rogers pcb laminates, are specialized substrates used in the manufacturing of printed circuit boards. These materials are known for their exceptional electrical performance, thermal stability, and mechanical reliability. Unlike traditional FR-4 materials, Rogers laminates are engineered to operate effectively at high frequencies, making them essential for advanced electronic applications. Key characteristics of Rogers PCB materials include low dielectric loss, high thermal conductivity, and stable dielectric constants, which contribute to improved signal integrity and performance.

Applications and Advantages of Rogers PCB Materials

The applications of Rogers PCB materials span a wide range of industries. In telecommunications, they are utilized in RF and microwave circuits, where high-frequency signal transmission is crucial. In aerospace, Rogers laminates are favored for their ability to withstand extreme environmental conditions while maintaining performance. Additionally, the medical field relies on Rogers materials for devices that demand high precision and reliability, such as imaging systems and diagnostic equipment.

The advantages of using Rogers PCB materials are significant. Their low loss characteristics enhance signal clarity, which is vital in high-speed applications. Furthermore, Rogers laminates offer better thermal management compared to traditional materials, allowing for efficient heat dissipation. This combination of benefits makes rogers pcb laminates a preferred choice for engineers seeking reliable and high-performance solutions in the rapidly evolving electronics landscape.

Overview of Rogers Laminates

Rogers laminates are a diverse range of high-performance materials designed for various applications in the electronics industry. Among these, the RO4000 series and TC series stand out for their unique properties and suitability for specific uses.

RO4000 Series

The RO4000 series is renowned for its excellent electrical characteristics, particularly in high-frequency applications. Key products in this series include RO4003C, RO4350B, and RO4006. These laminates are characterized by low dielectric constants and low loss tangents, making them ideal for RF and microwave circuits.

- RO4003C: This laminate features a dielectric constant of approximately 3.38 and is widely used in communication devices, automotive radar, and satellite systems due to its stable performance over a broad frequency range.

- RO4350B: With a dielectric constant of around 3.48, this material is preferred for high-speed digital applications, offering superior thermal stability and low moisture absorption.

- RO4006: Known for its excellent thermal conductivity, RO4006 is suitable for high-power applications, providing effective heat dissipation and maintaining performance under extreme conditions.

TC Series

The TC series, including materials like TC350 and TC600, focuses on thermal conductivity and dielectric stability. These laminates are engineered for applications that require efficient heat management alongside reliable electrical performance.

- TC350: This laminate has a high thermal conductivity, making it suitable for applications where heat dissipation is critical, such as in power amplifiers and high-density interconnects.

- TC600: With even higher thermal conductivity, TC600 is ideal for advanced applications in telecommunications and aerospace, where both thermal and electrical performance are paramount.

Applications and Features

The various Rogers laminates are utilized across numerous industries. Their ability to perform under high frequencies and temperatures makes them ideal for telecommunications, automotive, medical devices, and aerospace applications. Features such as low dielectric loss and thermal stability contribute to improved signal integrity and reliability, which are essential in modern electronic systems.

Rogers laminates, particularly those in the RO4000 series and TC series, offer a versatile range of materials tailored for high-performance applications. Their unique properties make them indispensable in advancing technology and enhancing the performance of electronic devices.

Key Products in the Rogers PCB Line

Rogers Corporation offers a variety of high-performance materials tailored to meet the demands of modern electronics. Among these, Rogers 3000, Rogers 5880, and Rogers Foam stand out for their unique properties and applications.

Rogers 3000

Rogers 3000 series materials are specifically designed for high-frequency applications. These laminates feature a low dielectric constant and low loss tangent, which significantly enhances signal integrity.

- Key Features: The Rogers 3000 series exhibits excellent thermal stability, high mechanical strength, and minimal moisture absorption. This combination of properties makes it suitable for demanding environments.

- Applications: Common applications include RF circuit boards, microwave circuits, and antenna designs. The materials are particularly effective in telecommunications, where high-frequency performance is critical, and in automotive applications, where reliability under extreme conditions is necessary.

Rogers 5880

Rogers 5880 is another notable product, designed for high-frequency and high-speed applications. This laminate is known for its excellent electrical characteristics and thermal management capabilities.

- Use Cases: Rogers 5880 is widely used in advanced telecommunications equipment, satellite communications, and high-speed digital circuits. Its low loss properties make it particularly valuable for applications that demand signal clarity and precision.

- Performance Advantages: One of the key advantages of Rogers 5880 is its ability to maintain performance over a wide range of temperatures and frequencies. This makes it suitable for applications in harsh environments where temperature fluctuations can impact performance.

Rogers Foam

Rogers Foam is a unique material that combines the lightweight properties of foam with the electrical performance of traditional laminates. This product is particularly useful in applications where weight reduction is critical.

- Applications: Rogers Foam is ideal for high-frequency circuits, including antenna substrates and lightweight RF components. Its lightweight nature makes it a preferred choice in aerospace and portable electronic devices, where reducing weight can enhance overall efficiency.

- Benefits in High-Frequency Circuits: The foam structure allows for excellent dielectric performance while minimizing overall material thickness. This contributes to tighter component spacing and improved design flexibility, making it easier to meet the compact design requirements of modern electronics.

The Rogers 3000 series, Rogers 5880, and Rogers Foam represent key products in the Rogers PCB line, each offering unique features and benefits tailored to specific applications. These materials are essential for enhancing the performance, reliability, and efficiency of high-frequency electronic devices.

Comparison of Rogers 4003C and 4350B

Rogers 4003C and Rogers 4350B are two prominent materials in the Rogers PCB lineup, each tailored for specific applications in the electronics industry. While both materials are designed for high-frequency performance, they possess distinct characteristics that make them suitable for different use cases.

Main Differences

- Dielectric Constant:

- Rogers 4003C: This laminate has a dielectric constant (Dk) of approximately 3.38, which allows for good performance in RF and microwave applications while ensuring minimal signal loss.

- Rogers 4350B: With a slightly higher dielectric constant of around 3.48, Rogers 4350B offers enhanced electrical performance, particularly in applications where a stable Dk is critical over varying temperatures and frequencies.

2. Loss Tangent:

- Rogers 4003C: The loss tangent of 4003C is typically around 0.0027, making it suitable for high-frequency applications but with a moderate performance profile.

- Rogers 4350B: This material has a lower loss tangent of approximately 0.0030, providing better signal integrity and efficiency, particularly beneficial for high-speed digital applications.

3. Thermal Stability:

- Rogers 4003C: While it offers good thermal stability, it is generally less robust than 4350B when subjected to extreme temperatures.

- Rogers 4350B: Known for its superior thermal stability, 4350B can withstand higher operating temperatures, making it a better choice for demanding applications.

Performance Comparison

- Signal Integrity: Both materials perform well in high-frequency environments, but Rogers 4350B typically provides better signal integrity due to its lower loss tangent. This advantage is crucial for applications like satellite communications and high-speed digital circuits.

- Temperature Coefficient of Dielectric Constant (TC): Rogers 4350B has a more stable TC, which ensures consistent performance across a wider temperature range. This makes it more reliable in applications subject to fluctuating thermal conditions.

Applications

- Rogers 4003C: This laminate is commonly used in RF applications, antennas, and general microwave circuits. Its performance is adequate for most telecommunications applications, making it a popular choice for mid-range designs.

- Rogers 4350B: This material is ideal for high-speed digital applications, such as high-frequency circuit boards, automotive radar systems, and advanced telecommunications. Its superior thermal and electrical properties make it the preferred option for critical applications that demand high reliability and performance.

Cost Consideration

- Rogers 4003C: Generally, 4003C is more cost-effective compared to 4350B. It is often chosen for projects with budget constraints while still requiring decent performance.

- Rogers 4350B: While it is typically more expensive due to its enhanced properties, the investment often pays off in applications where performance and reliability are paramount. The choice between these two materials ultimately depends on the specific needs of the project, balancing performance requirements with budget considerations.

While both Rogers 4003C and 4350B are excellent materials for high-frequency applications, their differences in dielectric constant, loss tangent, thermal stability, and cost make them suitable for distinct use cases. Understanding these differences helps engineers make informed decisions when selecting the appropriate laminate for their specific applications.

Understanding the Rogers 4000 Series Material

The Rogers 4000 series materials are a prominent line of high-frequency laminates designed to meet the increasing demands of modern electronics. These materials are engineered for superior electrical performance, thermal stability, and mechanical reliability, making them essential for a wide range of applications in telecommunications, aerospace, and advanced electronics.

Characteristics and Advantages of Rogers 4000 Series Materials

- Low Dielectric Constant:

- The Rogers 4000 series features low dielectric constants, which are crucial for minimizing signal loss in high-frequency applications. This characteristic enhances the overall performance of circuits by ensuring efficient signal transmission.

2. Low Loss Tangent:

- These materials exhibit low loss tangents, which means that they dissipate less energy as heat during signal transmission. This property is vital for applications that require high signal integrity and performance.

3. Thermal Stability:

- Rogers 4000 series laminates are designed to withstand high temperatures without degrading. This thermal stability is essential for applications in harsh environments, where fluctuations in temperature could adversely affect performance.

4. Moisture Resistance:

- The materials in this series are engineered to resist moisture absorption, which can lead to delamination and degradation of performance over time. This moisture resistance ensures long-term reliability in various operating conditions.

5. Mechanical Strength:

- Rogers 4000 series laminates possess excellent mechanical properties, making them suitable for complex geometries and high-density interconnects. Their durability ensures that they can withstand the rigors of manufacturing and end-use applications.

Applications of Rogers 4000 Series Materials

The Rogers 4000 series is utilized across various industries, including:

- Telecommunications: The series is widely used in RF and microwave circuits, antennas, and cellular base stations, where high-frequency performance and reliability are critical.

- Aerospace: In this sector, the materials are employed in radar systems, satellite communications, and navigation devices, where thermal stability and mechanical strength are essential.

- Medical Devices: Rogers 4000 series materials are also used in medical imaging systems and diagnostic equipment, where precision and reliability are paramount.

Technical Specifications of Rogers 4350B

Rogers 4350B is one of the flagship products within the 4000 series, designed specifically for high-performance applications.

- Dielectric Constant: Approximately 3.48, providing stable performance across a range of frequencies.

- Loss Tangent: Around 0.0030, which contributes to improved signal integrity and efficiency.

- Temperature Coefficient of Dielectric Constant (TC): Exhibits a low TC, ensuring consistent performance even with temperature variations.

- Thermal Conductivity: Higher thermal conductivity compared to other materials, allowing for effective heat dissipation in high-power applications.

- Moisture Absorption: Very low moisture absorption rate, enhancing long-term reliability and performance stability.

Applications of Rogers 4350B

Rogers 4350B is particularly suitable for:

- High-Speed Digital Circuits: Its excellent electrical properties make it ideal for high-speed interconnects and digital applications that require minimal signal degradation.

- RF Applications: Commonly used in RF amplifiers, filters, and antenna systems where signal clarity is crucial.

- Automotive Radar Systems: The material’s thermal stability and durability make it a reliable choice for advanced automotive applications, such as collision avoidance systems.

The Rogers 4000 series materials, particularly Rogers 4350B, offer a combination of excellent electrical performance, thermal stability, and mechanical strength, making them highly versatile for a wide range of demanding applications in the electronics industry.

Benefits of Using Rogers Laminates

Rogers laminates offer numerous advantages that make them highly suitable for high-frequency and high-speed electronic applications. These benefits stem from their unique material properties, which address the specific demands of modern electronic designs.

Advantages of Rogers Laminates in High-Frequency and High-Speed Applications

- Enhanced Electrical Performance:

- Rogers laminates are engineered with low dielectric constants and low loss tangents, which are critical for maintaining signal integrity in high-frequency applications. This means less energy is lost as signals propagate, ensuring clearer and more reliable transmission.

2. Thermal Stability:

- The high thermal stability of Rogers materials allows them to perform well under extreme conditions. This is particularly important in high-speed circuits where heat generation can lead to performance degradation. The ability to withstand elevated temperatures without compromising integrity is essential for applications in telecommunications and aerospace.

3. Durability and Mechanical Strength:

- Rogers laminates are known for their mechanical robustness, making them ideal for applications that require complex geometries and high-density interconnects. Their durability ensures longevity in various environments, including those with vibrations and thermal fluctuations.

4. Moisture Resistance:

- The low moisture absorption rates of Rogers laminates contribute to their reliability, particularly in humid or fluctuating environmental conditions. This characteristic minimizes the risk of delamination and performance degradation over time.

Impact on Signal Integrity and Thermal Management

- Signal Integrity:

- The combination of low dielectric loss and stable dielectric constants in Rogers laminates significantly enhances signal integrity. This is especially critical in applications such as RF circuits and high-speed digital systems, where even minor losses can lead to data corruption or signal distortion. By using Rogers materials, engineers can achieve tighter control over signal characteristics, resulting in improved performance in communication devices and other electronics.

2. Thermal Management:

- Effective thermal management is crucial in high-power applications, and Rogers laminates excel in this area. Their ability to conduct heat away from critical components helps maintain optimal operating temperatures, preventing thermal buildup that can impair performance or lead to failure. The thermal conductivity of materials like Rogers 5880 and the TC series ensures that heat is efficiently dissipated, enabling designs that can handle high power levels without sacrificing reliability.

Rogers laminates provide significant benefits for high-frequency and high-speed electronic applications. Their enhanced electrical performance, durability, moisture resistance, and thermal stability contribute to improved signal integrity and effective thermal management. As the demand for more sophisticated and reliable electronic systems continues to grow, the advantages offered by Rogers laminates make them an invaluable choice for engineers and designers striving for excellence in their projects.

FQAs Abut Rogers PCB Laminates

Rogers PCB material refers to a line of high-performance laminates produced by Rogers Corporation, specifically designed for high-frequency and high-speed electronic applications. These materials are known for their excellent electrical properties, thermal stability, and mechanical strength, making them ideal for use in telecommunications, aerospace, and other advanced technologies. Rogers PCBs are widely used in RF circuits, microwave applications, and high-speed digital circuits due to their low dielectric constant and low loss tangent.

The main differences between Rogers 4003C and Rogers 4350B lie in their dielectric properties and applications:

Dielectric Constant: Rogers 4003C has a dielectric constant of approximately 3.38, while Rogers 4350B has a slightly higher dielectric constant of around 3.48. This affects how signals propagate through the materials.

Loss Tangent: Rogers 4003C has a loss tangent of about 0.0027, making it suitable for RF applications. In contrast, Rogers 4350B has a lower loss tangent of approximately 0.0030, providing better signal integrity, especially in high-speed digital applications.

Thermal Stability: Rogers 4350B offers superior thermal stability, making it more suitable for applications subjected to higher temperatures and varying environmental conditions.

Applications: While both materials are used in RF and microwave applications, Rogers 4003C is often preferred for general RF designs, while Rogers 4350B is more suitable for high-speed digital and advanced telecommunications applications.

The Rogers 4000 series materials are a family of high-frequency laminates designed for use in advanced electronic applications. This series includes various products, such as Rogers 4003C, 4350B, and others, each tailored to meet specific performance requirements. The 4000 series materials are characterized by:

Low Dielectric Constants: Ensuring minimal signal loss and improved transmission efficiency.

Low Loss Tangents: Providing better signal integrity for high-frequency applications.

Thermal Stability: Capable of withstanding higher temperatures, making them suitable for demanding environments.

Moisture Resistance: Reducing the risk of performance degradation due to humidity.

These materials are widely used in telecommunications, aerospace, automotive radar systems, and other high-tech industries.

Rogers 4350B is a specific type of laminate within the Rogers 4000 series, designed for high-performance applications that require excellent electrical and thermal properties. Key characteristics of Rogers 4350B include:

Dielectric Constant: Approximately 3.48, providing stable performance over a wide frequency range.

Loss Tangent: Around 0.0030, contributing to enhanced signal integrity, particularly in high-speed digital circuits.

Thermal Conductivity: Higher thermal conductivity compared to many traditional PCB materials, aiding in heat dissipation.

Applications: Commonly used in RF amplifiers, filters, antennas, and high-speed digital circuits, particularly in telecommunications and aerospace applications.

Rogers 4350B is valued for its reliability and performance, making it a preferred choice for critical electronic designs.