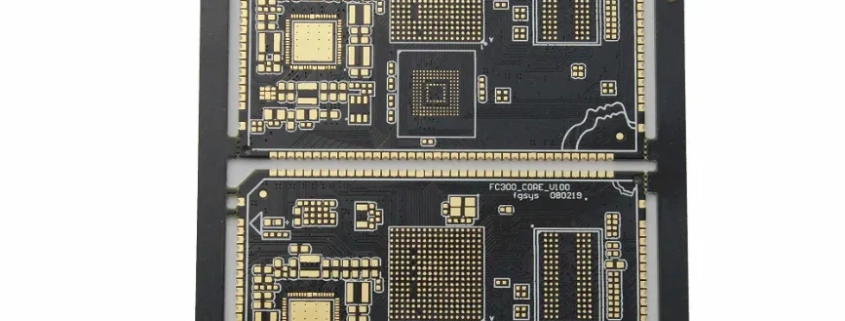

Advancing Integration: Chip Stacking Technology

Chip on Wafer on Substrate (CoWoS) technology revolutionizes integrated circuit packaging by vertically stacking multiple chips on a single substrate, enhancing performance and reducing form factor. Its principle involves bonding chips directly onto a silicon interposer or substrate, enabling shorter interconnection lengths for faster data transfer. CoWoS finds applications in high-performance computing, artificial intelligence, and networking, where increased bandwidth and reduced latency are critical. Its significance lies in overcoming the limitations of traditional packaging methods, offering superior thermal management and electrical performance. CoWoS plays a pivotal role in integrated circuit design by enabling the integration of heterogeneous components in a compact form, facilitating the development of advanced electronic systems with unprecedented capabilities.

Process Flow of CoWoS

The process flow of Chip on Wafer on Substrate (CoWoS) involves several intricate steps to achieve the vertical stacking of chips on a substrate, ensuring efficient interconnections and optimal performance.

Preparation of Chips, Wafers, and Substrates

– Chips Preparation: High-quality chips are manufactured separately with specific functionalities.

– Wafer Fabrication: Wafers are prepared with precision to accommodate multiple chips.

– Substrate Preparation: The substrate, often a silicon interposer, is fabricated with the necessary features for chip attachment and interconnections.

Stacking and Bonding Process

– Chip Positioning: Chips are accurately positioned on the substrate, ensuring alignment for subsequent processing.

– Bonding: Various bonding techniques like microbumps or through-silicon vias (TSVs) are used to attach chips onto the substrate securely.

– Thinning: The backside of the stacked chips is thinned to reduce thickness and enhance thermal dissipation.

Addition of Packaging Layers

– Dielectric Layer Deposition: Dielectric layers are deposited on the stacked chips to provide insulation and protect against environmental factors.

– Metal Layer Deposition: Metal layers are added for creating interconnections between the chips and the substrate, forming the basis for electrical pathways.

– Through-Silicon Via Formation: TSVs are created to establish vertical electrical connections between the chips and the substrate, facilitating efficient data transmission.

Interconnects and Testing

– Interconnect Formation: Interconnects between the chips and the substrate are formed using advanced techniques like copper pillar bumping or redistribution layer (RDL) routing.

– Testing: Comprehensive testing procedures are carried out to ensure the reliability and functionality of the CoWoS package, including electrical, thermal, and mechanical testing.

Packaging and Finalization

– Encapsulation: The entire CoWoS assembly is encapsulated with protective materials to safeguard against external factors such as moisture and physical damage.

– Final Testing and Quality Assurance: Rigorous testing and quality checks are performed to verify the performance and reliability of the packaged CoWoS device before it is ready for deployment.

The meticulous execution of these steps ensures the successful implementation of CoWoS technology, enabling the creation of high-performance integrated circuit packages with enhanced functionality and compact form factors.

Applications of Chip on Wafer on Substrate

Chip on Wafer on Substrate (CoWoS) technology offers versatile applications across various industries, leveraging its ability to integrate multiple chips into compact packages with enhanced performance and efficiency.

Types of Chips Using CoWoS Technology

– High-Performance Processors: CoWoS enables the integration of multiple processor cores, cache memory, and specialized accelerators onto a single package, catering to the demands of intensive computing tasks in data centers and supercomputers.

– Graphics Processors (GPUs): CoWoS facilitates the stacking of high-density memory and GPU cores, delivering superior graphics rendering capabilities for gaming consoles, virtual reality (VR) systems, and professional graphics workstations.

– Other Integrated Circuits: CoWoS is also employed in the integration of application-specific integrated circuits (ASICs), field-programmable gate arrays (FPGAs), and system-on-chip (SoC) designs, offering tailored solutions for diverse applications such as automotive, aerospace, and consumer electronics.

Application Cases in Various Fields

– Artificial Intelligence (AI): CoWoS plays a crucial role in AI applications by enabling the integration of specialized AI accelerators, such as tensor processing units (TPUs) and neuromorphic computing units, into high-performance computing systems. These systems are utilized for tasks like deep learning, machine vision, and natural language processing, enhancing the efficiency and scalability of AI algorithms.

– Cloud Computing: In cloud computing infrastructures, CoWoS facilitates the development of high-density server solutions with optimized performance per watt. By stacking multiple processing units, memory modules, and network accelerators onto a single package, CoWoS enhances the computational power and bandwidth of cloud servers, enabling faster data processing and improved scalability for cloud-based applications and services.

– Communications: CoWoS technology enhances the performance and energy efficiency of communication systems, enabling the integration of multiple radio frequency (RF) components, digital signal processors (DSPs), and networking accelerators into compact modules. These modules are employed in wireless base stations, satellite communication systems, and 5G network infrastructure, enabling high-speed data transmission, low-latency communication, and efficient spectrum utilization.

By leveraging CoWoS technology, developers and engineers can create innovative solutions across a wide range of applications, driving advancements in computing, communication, and data processing capabilities.

Difference between TSMC CoWoS and InFO

TSMC’s Chip on Wafer on Substrate (CoWoS) and Integrated Fan-Out (InFO) packaging technologies are both advanced packaging solutions offered by Taiwan Semiconductor Manufacturing Company (TSMC), each with its unique features and applications.

Similarities and Differences

– Similarities:

– Both CoWoS and InFO technologies involve the stacking and interconnection of multiple chips within a single package.

– Both technologies aim to improve performance, reduce form factor, and enhance integration density compared to traditional packaging methods.

– Differences:

– Structural Differences: CoWoS involves stacking chips on a silicon interposer or substrate, while InFO packages chips within a mold compound without the need for an interposer.

– Interconnect Technology: CoWoS typically uses through-silicon vias (TSVs) for vertical interconnections, whereas InFO employs redistribution layers (RDL) for horizontal interconnections within the package.

– Integration Level: CoWoS allows for heterogeneous integration of different types of chips, while InFO is primarily used for the integration of homogeneous chips within the same package.

Advantages and Application Scenarios

– TSMC CoWoS:

– Advantages: CoWoS offers high bandwidth, low latency, and excellent thermal management due to the use of TSVs and the silicon interposer. It is suitable for applications requiring heterogeneous integration, such as high-performance computing, networking, and artificial intelligence.

– Application Scenarios: CoWoS is ideal for complex system-on-chip (SoC) designs, where multiple specialized chips, such as processors, memory, and accelerators, need to be integrated into a single package to meet the performance requirements of demanding applications.

– TSMC InFO:

– Advantages: InFO provides superior flexibility, scalability, and cost-effectiveness compared to CoWoS, as it eliminates the need for a silicon interposer and simplifies the packaging process. It is suitable for applications requiring high-volume production and compact form factors, such as mobile devices, wearables, and consumer electronics.

– Application Scenarios: InFO is well-suited for mobile processors, RF chips, and application-specific integrated circuits (ASICs) used in smartphones, tablets, and IoT devices, where small form factor, low power consumption, and cost efficiency are essential considerations.

In summary, TSMC’s CoWoS and InFO technologies offer distinct advantages and are tailored for different application scenarios, allowing designers to choose the most suitable packaging solution based on their specific requirements for performance, cost, and form factor.

Future Prospects of Chip on Wafer on Substrate

The future of Chip on Wafer on Substrate (CoWoS) technology is filled with promising advancements and opportunities, driven by ongoing innovations in packaging techniques and emerging applications across various industries.

Development Trends of CoWoS Technology

– Improved Packaging Density: Future CoWoS implementations are expected to achieve even higher levels of integration density, enabling the stacking of an increasing number of chips within a single package. This will result in more powerful and compact electronic systems with enhanced functionality.

– Enhanced Performance: Continued advancements in CoWoS technology will lead to improvements in signal propagation speed, interconnect bandwidth, and overall system performance. These enhancements will enable the development of high-performance computing solutions capable of handling complex computational tasks with greater efficiency.

– Reduced Power Consumption: Future CoWoS designs will focus on minimizing power consumption through the use of advanced power management techniques, low-power components, and efficient thermal dissipation methods. This will result in energy-efficient electronic systems that can operate for longer durations without compromising performance.

Potential Applications in Emerging Technology Fields

– Quantum Computing: CoWoS technology holds significant potential for advancing the development of quantum computing systems by enabling the integration of diverse quantum components, such as qubits, control electronics, and classical processors, into a single package. This integration will facilitate the creation of scalable and robust quantum computing platforms capable of solving complex computational problems with unprecedented speed and accuracy.

– Internet of Things (IoT): CoWoS offers unique advantages for IoT applications by enabling the integration of diverse sensors, processors, and communication modules into compact and energy-efficient packages. These packages can be deployed in various IoT devices, including smart sensors, wearable devices, and industrial monitoring systems, enabling real-time data acquisition, processing, and communication in IoT networks.

– Autonomous Driving: CoWoS technology has the potential to revolutionize the automotive industry by enabling the integration of advanced sensing, computing, and control systems into autonomous vehicles. By stacking multiple chips, such as lidar sensors, image processors, and AI accelerators, onto a single substrate, CoWoS enables the development of highly efficient and reliable autonomous driving systems capable of navigating complex environments with precision and safety.

In conclusion, the future of CoWoS technology is bright, with continued advancements expected in packaging density, performance, and power consumption. These advancements will open up exciting opportunities for CoWoS in emerging technology fields such as quantum computing, IoT, and autonomous driving, where integrated and high-performance electronic systems are in high demand.

FAQs about chip on wafer on substrate

The process of chip on wafer on substrate involves vertically stacking multiple chips on a single substrate or interposer, creating a compact and integrated package. This process includes the preparation of chips, wafers, and substrates, followed by the stacking and bonding of chips onto the substrate, and the addition of packaging layers and interconnects to establish electrical connections between the chips and the substrate.

Chips using CoWoS technology typically include high-performance processors, graphics processors (GPUs), application-specific integrated circuits (ASICs), and system-on-chip (SoC) designs. CoWoS enables the integration of these chips into a single package, enhancing performance, reducing form factor, and enabling heterogeneous integration for diverse applications.

The main difference between TSMC’s CoWoS and Integrated Fan-Out (InFO) packaging technologies lies in their structural and interconnect approaches. CoWoS involves stacking chips on a silicon interposer or substrate and using through-silicon vias (TSVs) for vertical interconnections. InFO, on the other hand, packages chips within a mold compound without the need for an interposer, using redistribution layers (RDL) for horizontal interconnections within the package. Additionally, CoWoS is suitable for heterogeneous integration, while InFO is primarily used for homogeneous integration within the same package.

The TSMC equivalent of EMIB (Embedded Multi-die Interconnect Bridge) is CoWoS-EMIB. CoWoS-EMIB combines the CoWoS packaging technology with EMIB technology to enable the integration of multiple chips and interconnects within a single package, providing high bandwidth, low latency, and efficient thermal management for advanced electronic systems.