Intel’s Cutting-Edge Glass Substrate: Powering Future Devices

Glass substrates play a pivotal role in the electronics industry, serving as a foundation for various electronic components and devices. Their versatility, durability, and transparency make them indispensable in applications ranging from display panels to semiconductor manufacturing. In recent years, the emergence of Intel Glass Substrate has marked a significant advancement in the technology sector. This innovative product not only meets the stringent requirements of modern electronic devices but also offers breakthrough solutions for enhanced performance and reliability. With Intel Glass Substrate, the boundaries of technological possibilities are continuously being pushed, ushering in a new era of efficiency and sophistication in electronics manufacturing.

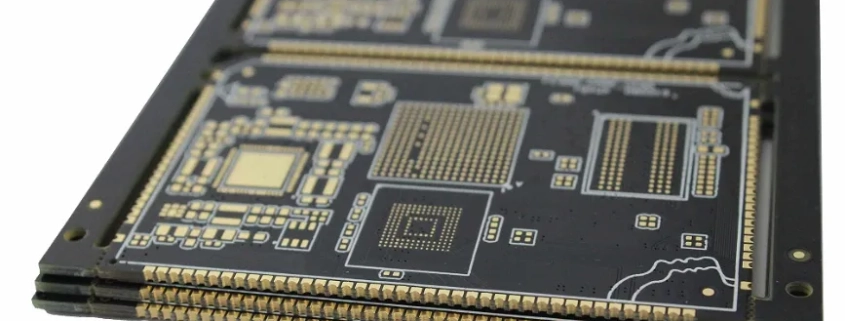

Definition and Characteristics of Glass Substrate

Glass substrates are flat, rigid surfaces made of glass materials with specific properties tailored for electronic applications. Typically, they possess exceptional transparency, thermal stability, and mechanical strength, making them ideal for supporting and insulating electronic components.

What is a Glass Substrate?

A glass substrate serves as a stable foundation upon which various electronic components are fabricated or assembled. It provides a smooth, uniform surface for the deposition of thin films, such as semiconductors, conductive layers, or insulating materials. The composition and thickness of the glass substrate can vary depending on the intended application, with options ranging from soda-lime glass to specialized compositions like borosilicate or quartz glass.

Fundamental Characteristics

Glass substrates exhibit several fundamental characteristics that make them well-suited for electronic applications. Their high optical transparency allows for efficient light transmission, making them ideal for display technologies like LCDs, OLEDs, and touchscreens. Moreover, glass substrates offer excellent thermal stability, ensuring consistent performance under varying temperature conditions. Additionally, their mechanical durability and chemical resistance contribute to the long-term reliability of electronic devices.

Widespread Applications

The applications of glass substrates in modern electronic devices are vast and diverse. They are integral components in flat-panel displays, providing support for the thin-film transistors (TFTs) and color filters in LCDs, as well as the organic layers in OLEDs. Glass substrates are also used in the manufacturing of photovoltaic cells for solar panels, where their transparency and durability are crucial for maximizing sunlight absorption and long-term performance. Furthermore, glass substrates find applications in semiconductor manufacturing, MEMS (Micro-Electro-Mechanical Systems) devices, and optical components, highlighting their versatility and indispensability in various electronic industries.

Specifications and Features of Intel Glass Substrate

Intel Glass Substrate represents a cutting-edge advancement in the realm of electronic substrates, offering a range of specifications and features tailored to meet the demands of modern technology.

Specifications and Dimensions

Intel Glass Substrate is manufactured to precise specifications, ensuring uniformity and consistency in performance across various applications. Its dimensions typically vary based on specific requirements, with options available for different sizes and thicknesses to accommodate diverse electronic devices and manufacturing processes.

Advantages Over Traditional Substrates

1. Thickness: Intel Glass Substrate boasts a remarkably thin profile compared to traditional substrates, contributing to overall device miniaturization and enhanced portability. This reduced thickness not only conserves space within electronic devices but also facilitates the integration of multiple components into compact form factors.

2. Material Properties: The material properties of Intel Glass Substrate are optimized for superior performance and reliability. With excellent thermal stability and mechanical strength, it provides a robust foundation for electronic components, ensuring long-term durability and consistent operation under challenging conditions.

3. Manufacturing Consistency: Intel Glass Substrate is engineered with a focus on manufacturing consistency, allowing for high-yield production processes and minimal variability in product performance. This reliability is essential for meeting the stringent quality standards of advanced electronic devices and ensuring customer satisfaction.

4. Enhanced Functionality: Beyond basic substrate functionality, Intel Glass Substrate offers additional features and capabilities designed to enhance the performance of electronic devices. These may include specialized coatings for improved electrical conductivity, optical enhancements for enhanced display clarity, or surface treatments for enhanced adhesion and compatibility with other materials.

Overall, Intel Glass Substrate represents a significant advancement in substrate technology, providing unparalleled performance, reliability, and versatility for a wide range of electronic applications. Its innovative design and superior features make it an ideal choice for next-generation electronic devices, driving innovation and advancement in the technology industry.

Manufacturing Process of Intel Glass Substrate

The manufacturing process of Intel Glass Substrate involves a series of intricate steps and advanced techniques to achieve the desired specifications and features. From raw material preparation to final inspection, each stage is meticulously executed to ensure high-quality and consistent performance.

Process Flow and Technical Details

1. Raw Material Selection: The process begins with the careful selection of high-quality glass materials suited for electronic applications. These materials undergo rigorous testing to assess their purity, transparency, and thermal properties, ensuring optimal performance in the final product.

2. Glass Cutting and Shaping: The selected glass materials are precisely cut and shaped according to the desired dimensions and specifications of Intel Glass Substrate. Advanced cutting techniques, such as laser cutting or diamond sawing, are employed to achieve accuracy and uniformity in substrate size.

3. Surface Preparation: The surfaces of the glass substrates are meticulously cleaned and prepared to remove any impurities or contaminants that could affect subsequent processing steps. This involves thorough cleaning, rinsing, and drying processes to ensure a pristine substrate surface.

4. Deposition of Functional Layers: Various functional layers, such as conductive coatings, insulating films, or optical enhancements, are deposited onto the glass substrate surface using advanced deposition techniques like physical vapor deposition (PVD) or chemical vapor deposition (CVD). These layers are precisely controlled to achieve the desired properties and performance characteristics.

5. Annealing and Thermal Treatment: After deposition, the glass substrates undergo annealing and thermal treatment processes to enhance their mechanical strength, thermal stability, and overall reliability. This step helps to relieve internal stresses and improve the structural integrity of the substrates.

6. Quality Control and Inspection: Throughout the manufacturing process, stringent quality control measures are implemented to monitor and ensure the consistency and reliability of Intel Glass Substrate. Advanced inspection techniques, including optical microscopy, surface profilometry, and electrical testing, are employed to detect any defects or irregularities and ensure compliance with specifications.

Intel’s Innovation and Leading Position in Glass Substrate Manufacturing

Intel stands at the forefront of glass substrate manufacturing, leveraging its advanced research and development capabilities, as well as its expertise in semiconductor technology, to drive innovation and excellence in substrate manufacturing. By continuously pushing the boundaries of material science and manufacturing technology, Intel has developed proprietary processes and techniques that enable the production of high-performance glass substrates with unparalleled precision, reliability, and functionality. This commitment to innovation and quality has solidified Intel’s leading position in the glass substrate market, paving the way for groundbreaking advancements in electronic devices and technologies.

Applications of Intel Glass Substrate

Intel Glass Substrate finds extensive applications across various industries, owing to its exceptional performance, reliability, and versatility. From the semiconductor industry to the communication sector, Intel Glass Substrate contributes to the development of cutting-edge electronic devices and technologies.

Semiconductor Industry

In the semiconductor industry, Intel Glass Substrate serves as a critical component in the manufacturing of integrated circuits (ICs), microprocessors, and other semiconductor devices. Its high thermal stability and excellent planarity make it an ideal substrate for lithographic processes, where precise patterning and etching are essential for creating intricate circuit patterns on silicon wafers. Additionally, Intel Glass Substrate’s superior electrical insulation properties help to minimize signal loss and interference, enabling the production of high-performance semiconductor devices with enhanced reliability and efficiency.

Display Technology

In the field of display technology, Intel Glass Substrate plays a crucial role in the fabrication of flat-panel displays, including liquid crystal displays (LCDs), organic light-emitting diode displays (OLEDs), and microLED displays. Its high optical transparency and uniform surface quality contribute to vibrant image reproduction and improved viewing experiences for consumers. Furthermore, Intel Glass Substrate’s thin profile and lightweight design enable the development of slim and lightweight display devices, such as smartphones, tablets, and laptops, without compromising on performance or durability.

Communication Sector

In the communication sector, Intel Glass Substrate is utilized in the manufacturing of various components and devices, including optical fibers, waveguides, and photonic devices. Its low optical attenuation and high dielectric constant make it an excellent substrate material for optical communication systems, facilitating efficient transmission of data over long distances. Moreover, Intel Glass Substrate’s compatibility with advanced manufacturing processes, such as photolithography and thin-film deposition, enables the integration of complex optical and electronic components onto a single substrate, leading to the development of compact and high-performance communication devices.

Other Applications

Beyond the semiconductor industry and communication sector, Intel Glass Substrate finds applications in a wide range of other industries, including aerospace, automotive, medical, and consumer electronics. Its superior performance and reliability make it suitable for various applications, such as sensor technologies, MEMS devices, photovoltaic cells, and advanced packaging solutions. With its exceptional versatility and advanced features, Intel Glass Substrate continues to drive innovation and advancement across multiple industries, shaping the future of electronic devices and technologies.

Differences Between Glass Substrate and CPU Substrate

Glass substrates and CPU substrates serve distinct purposes in electronic devices, each with its own set of characteristics and applications. Contrasting the differences between the two provides insights into their respective materials, purposes, and advantages.

Materials

– Glass Substrate: Glass substrates are typically made of transparent materials such as soda-lime glass, borosilicate glass, or quartz glass. These materials offer excellent transparency, thermal stability, and mechanical strength, making them suitable for supporting and insulating electronic components in various devices.

– CPU Substrate: CPU substrates, on the other hand, are commonly composed of materials like silicon, ceramic, or fiberglass. These materials possess excellent electrical conductivity and thermal dissipation properties, crucial for transferring electrical signals and dissipating heat generated by the central processing unit (CPU).

Purposes

– Glass Substrate: Glass substrates primarily serve as a foundation for electronic components in devices such as displays, sensors, and photovoltaic cells. They provide a stable platform for depositing thin films and creating electronic circuits, enabling the integration of complex functionalities into compact and lightweight devices.

– CPU Substrate: CPU substrates are specifically designed to support the CPU in electronic devices, providing electrical connections between the CPU and other components such as memory modules, graphics cards, and peripheral devices. They facilitate the transmission of signals and power between the CPU and other parts of the system, ensuring efficient operation and performance.

Advantages and Applicability

– Glass Substrate: Glass substrates offer several advantages in specific scenarios, such as in display technologies where transparency and uniformity are critical for optimal viewing experiences. They also excel in applications requiring lightweight and thin form factors, such as smartphones, tablets, and wearable devices. Additionally, glass substrates are well-suited for applications where high optical transparency and thermal stability are essential, such as in optical communication systems and photovoltaic cells.

– CPU Substrate: CPU substrates provide advantages in scenarios where electrical conductivity, thermal dissipation, and signal integrity are paramount, such as in high-performance computing systems and server environments. Their ability to efficiently transfer electrical signals and dissipate heat helps to ensure the reliability and stability of the CPU, even under heavy workload conditions.

In summary, while both glass substrates and CPU substrates play crucial roles in electronic devices, they differ in terms of materials, purposes, and advantages. Understanding these differences enables engineers and designers to select the most appropriate substrate material for specific applications, optimizing device performance and functionality.

FAQs about intel glass substrate

A glass substrate is a flat, rigid surface made of glass material, often used as a foundation for electronic components in various devices. It provides support and insulation for thin films and electronic circuits, contributing to the functionality and performance of electronic devices.

The thickness of Intel glass substrate can vary depending on specific requirements and applications. However, Intel glass substrates are typically engineered to be remarkably thin compared to traditional substrates, contributing to device miniaturization and enhanced portability.

Glass substrates offer several benefits, including exceptional transparency, thermal stability, and mechanical strength. They provide a stable platform for electronic components, facilitate efficient light transmission in display technologies, and contribute to the reliability and durability of electronic devices. Additionally, glass substrates enable the integration of complex functionalities into compact and lightweight devices, making them ideal for a wide range of applications.

The substrate of a CPU, often referred to as a CPU substrate or package substrate, is typically composed of materials like silicon, ceramic, or fiberglass. It serves as a foundation for the CPU and provides electrical connections between the CPU and other components in the system, such as memory modules, graphics cards, and peripheral devices. The substrate facilitates the transmission of signals and power, ensuring efficient operation and performance of the CPU in electronic devices.