Copper Core PCB vs Aluminium Core PCB Explained

A copper core PCB is a type of metal core PCB where a thick copper plate is used as the central substrate layer. Unlike standard FR4 boards, copper provides excellent heat dissipation, mechanical stability, and higher current carrying capacity. This makes copper core PCBs ideal for high-power electronics, LED modules, RF amplifiers, and automotive systems where thermal management is critical.

Structure and Materials of Copper Core PCBs

A copper core PCB typically has the following structure:

-

Copper core (baseplate): A solid copper plate ranging from 0.5 mm to several millimeters thick.

-

Dielectric layer: High thermal conductivity insulating material to electrically isolate the copper core and circuit traces.

-

Copper foil: Standard copper foil laminated on the dielectric, where circuits are etched.

What Type of Copper Is Used in PCBs?

Most PCBs use electrodeposited (ED) copper for its cost-effectiveness and rolled annealed (RA) copper for flexible and high-frequency applications. In copper core PCBs, both ED and RA copper can be applied depending on design requirements.

How Thick Is 1 oz Copper on a PCB?

1 oz copper corresponds to a thickness of about 35 µm (microns) or 1.37 mils. For copper core PCBs, thickness options range from 1 oz to 20 oz (35 µm to 700 µm), depending on the required current capacity and thermal performance.

Copper Core PCB vs. Other PCB Types

-

Copper Clad PCB: A traditional PCB made by laminating copper foil on FR4 or other substrates, not the same as copper core.

-

Copper Base PCB: Another term sometimes used interchangeably with copper core PCB.

-

Aluminium Core PCB: Uses an aluminum base instead of copper, cheaper but with lower thermal conductivity (~200 W/m·K vs. copper’s ~400 W/m·K).

-

Metal Core PCB Family: Includes aluminum, copper, and hybrid metal substrates.

Why Choose Copper Over Aluminum?

-

Higher thermal conductivity for demanding power applications.

-

Stronger mechanical stability under thermal cycling.

-

Lower coefficient of thermal expansion (CTE), reducing stress on solder joints.

Key Features and Benefits of Copper Core PCBs

-

Superior heat dissipation: Direct copper heatsink integration reduces hotspot risks.

-

High current carrying capacity: Ideal for power electronics and heavy copper designs.

-

Reliability under stress: Excellent dimensional stability in harsh thermal environments.

-

Better electrical performance: Lower resistance and improved signal integrity for RF circuits.

Copper Core PCB Manufacturing Process

Manufacturing copper core PCBs involves specialized processes:

-

Base preparation: Copper plates are precision-machined and cleaned.

-

Dielectric lamination: High-Tg, thermally conductive dielectric material is applied.

-

Copper foil bonding: Circuit layers are laminated on top.

-

Drilling and plating: Specialized drills are required to penetrate thick copper.

-

Etching and finishing: Surface finishes such as ENIG, OSP, HASL, or immersion silver are applied.

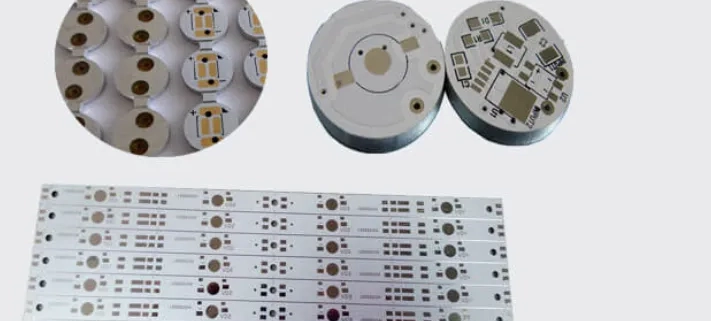

Applications of Copper Core PCBs

Copper core PCBs are widely used in:

-

Power electronics: IGBT modules, DC-DC converters.

-

Automotive: EV battery systems, LED headlights, motor controllers.

-

Aerospace & defense: High-reliability and high-power modules.

-

Telecommunications: 5G base stations, RF power amplifiers.

Copper Core PCB Cost and Pricing Factors

The price of copper core PCBs depends on:

-

Copper thickness (1 oz vs. heavy copper).

-

Board size and layer count.

-

Material selection (dielectric type, copper grade).

-

Prototype vs. mass production.

Generally, copper core PCBs are more expensive than aluminium core PCBs due to higher raw material and processing costs. However, their superior performance justifies the investment for high-reliability products.

China Copper Core PCB Manufacture

Some top copper core PCB manufacturers include:

-

ALCANTA PCB – high-performance copper-core PCBs for efficient thermal management and advanced electronics.

- JLCPCB – offering direct heatsink copper-cored PCBs for advanced cooling.

-

PCBonline – custom copper-based PCB fabrication.

-

PCBGOGO & PCBWay – prototype and small-batch copper core PCB services.

-

MCLPCB & Candor – specialty copper substrate solutions for high-power electronics.

These manufacturers provide options for prototypes, small-batch runs, and mass production, with varying price levels.

Design Considerations and Challenges

While copper core PCBs deliver excellent performance, engineers must consider:

-

Mechanical stress & weight – copper is heavy compared to aluminum.

-

Tool wear & drill cost – thick copper cores increase fabrication complexity.

-

Thermal simulation – essential to optimize heat paths.

-

Balancing performance vs. cost – especially in consumer electronics.

Conclusion

Copper core PCBs are the ultimate choice for applications demanding high power, high reliability, and excellent thermal management. Compared to aluminum core and traditional FR4 PCBs, they offer superior conductivity and mechanical stability. Although copper core PCB cost is higher, industries such as automotive, aerospace, and telecommunications increasingly adopt them for next-generation designs.