Mastering Electronic Substrates: Essential Insights

Electronic substrates are the backbone of modern electronics, facilitating the seamless integration of intricate circuits within devices. They serve as the foundation upon which electronic components are mounted, ensuring structural integrity and electrical connectivity. By understanding the intricacies of electronic substrates, engineers can optimize designs for enhanced performance and reliability. This article explores the multifaceted nature of electronic substrates, encompassing their definition, diverse types, and wide-ranging applications across industries such as telecommunications, automotive, aerospace, and consumer electronics. From ceramic substrates to advanced PCB materials, each substrate variant offers unique properties tailored to specific requirements, underscoring their indispensable role in the ever-evolving landscape of electronic engineering. Join us on a journey to unravel the complexities and significance of electronic substrates in powering the technologies of tomorrow.

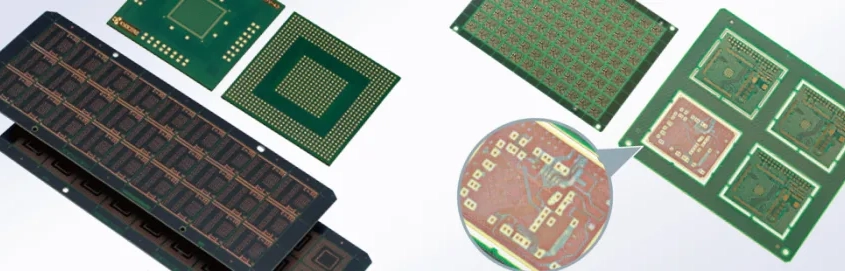

Understanding Electronic Substrates

What are Electronic Substrates?

Electronic substrates, also known as circuit substrates or PCB substrates, are foundational materials upon which electronic components and circuits are mounted and interconnected. These substrates provide a stable platform for the integration of various electronic elements, such as semiconductors, resistors, capacitors, and integrated circuits (ICs). Typically made from materials like fiberglass-reinforced epoxy, ceramics, or metal, electronic substrates offer mechanical support, electrical insulation, and signal transmission capabilities crucial for the proper functioning of electronic devices.

The Role of Electronic Substrates in Circuits

Electronic substrates serve several essential roles within circuits. Firstly, they provide a physical structure that holds electronic components securely in place, preventing damage from mechanical stress and environmental factors. Secondly, substrates facilitate electrical connections between components through conductive traces, vias, and pads etched or deposited onto their surface. These interconnections enable the flow of electrical signals between components, forming functional circuits. Additionally, electronic substrates often incorporate features like solder pads or lands for attaching components, ensuring robust solder joints and reliable electrical connections.

Significance of Electronic Substrates

The significance of electronic substrates lies in their foundational role in electronic device manufacturing and performance. They determine the overall structural integrity, electrical performance, and thermal management capabilities of electronic assemblies. By selecting appropriate substrate materials and designs, engineers can tailor the properties of electronic circuits to meet specific application requirements, such as high-speed data transmission, thermal dissipation, or miniaturization. Moreover, advancements in substrate technology contribute to the continual improvement of electronic devices, enabling innovations in areas like high-frequency communications, automotive electronics, medical devices, and more. As such, electronic substrates play a critical role in driving the evolution and advancement of modern technology.

Types of Electronic Substrates

Electronic Substrates vs. Ceramic Substrates

Characteristics and Differences: Electronic substrates and ceramic substrates are two common types of materials used in electronic device manufacturing, each with distinct characteristics and applications. Electronic substrates, typically made from materials like fiberglass-reinforced epoxy or polyimide, offer excellent mechanical strength, flexibility, and cost-effectiveness. They are widely used in applications where thermal management, electrical insulation, and signal integrity are critical. On the other hand, ceramic substrates, often composed of materials like alumina (Al2O3) or aluminum nitride (AlN), exhibit superior thermal conductivity, high temperature resistance, and dimensional stability. These properties make ceramic substrates ideal for applications requiring efficient heat dissipation, such as power electronics, LEDs, and high-frequency RF devices.

Introduction to Common Electronic Substrate Materials

Electronic substrates are manufactured using a variety of materials, each offering specific properties suited to different application requirements. Common materials include:

- Fiberglass-reinforced Epoxy: Offers good mechanical strength, electrical insulation, and cost-effectiveness, suitable for general-purpose electronics.

- Polyimide: Provides excellent flexibility, thermal stability, and chemical resistance, making it ideal for flexible circuits and applications in harsh environments.

- Ceramic (e.g., Alumina, Aluminum Nitride): Exhibits high thermal conductivity, temperature resistance, and dimensional stability, suitable for high-power and high-frequency applications.

Impact of Material Selection on Electronic Substrate Performance

The choice of substrate material significantly impacts the performance and reliability of electronic devices. Factors such as electrical properties, thermal conductivity, coefficient of thermal expansion (CTE), and cost must be carefully considered to ensure optimal performance. For instance, selecting a substrate with high thermal conductivity is crucial for heat dissipation in power electronics, while low CTE helps minimize stress during temperature fluctuations. Additionally, material compatibility with manufacturing processes, such as etching, plating, and soldering, is essential for achieving reliable circuit fabrication.

Typical Electronic Substrate Materials

Electronic substrates encompass a wide range of materials, each offering unique properties tailored to specific applications. Typical materials include fiberglass-reinforced epoxy, polyimide, and various ceramics such as alumina and aluminum nitride. These materials are selected based on factors such as mechanical strength, thermal conductivity, electrical insulation, and compatibility with manufacturing processes.

Classification of Electronic Substrates

Electronic substrates can be classified into different categories based on their composition, structure, and manufacturing processes. Common classifications include:

- Direct Bonded Copper (DBC) Substrates: Feature a copper layer bonded directly to a ceramic substrate, providing excellent thermal conductivity and electrical performance, commonly used in power electronics.

- Active Metal Brazed (AMB) Substrates: Utilize active metal brazing techniques to join ceramic substrates with metal layers, offering high thermal conductivity and reliability, suitable for high-power and high-frequency applications.

- Other specialized substrates may include variations of DBC or AMB substrates tailored to specific requirements or incorporating advanced materials and fabrication techniques to meet demanding performance criteria.

Applications of Electronic Substrates

The Role of Electronic Substrates in Semiconductors

Electronic substrates play a pivotal role in semiconductor manufacturing, providing the structural foundation and interconnectivity essential for the fabrication of integrated circuits (ICs) and other semiconductor devices. These substrates serve as the platform upon which semiconductor components are assembled and interconnected, enabling the creation of complex electronic circuits with high precision and reliability. In semiconductor applications, electronic substrates contribute to the miniaturization, performance optimization, and functionality enhancement of devices across a wide range of industries, including consumer electronics, telecommunications, automotive, and aerospace.

Importance of Electronic Substrates in Semiconductor Manufacturing

In semiconductor manufacturing, electronic substrates are critical for ensuring the performance, reliability, and manufacturability of semiconductor devices. They provide the necessary mechanical support, electrical connectivity, and thermal management capabilities required to integrate semiconductor components into functional circuits. The selection of appropriate substrate materials and designs is crucial for optimizing device performance, reducing manufacturing costs, and meeting stringent quality and reliability standards. Electronic substrates also play a vital role in addressing challenges such as signal integrity, power distribution, and thermal dissipation in semiconductor applications.

PCB (Printed Circuit Board) Materials and Manufacturing Processes

Printed Circuit Boards (PCBs) are a common type of electronic substrate used in a wide range of applications, from consumer electronics to industrial equipment. PCBs consist of a substrate material, typically fiberglass-reinforced epoxy, with conductive traces, vias, and pads etched or deposited onto its surface to create electrical pathways. The choice of PCB materials and manufacturing processes depends on factors such as application requirements, performance specifications, cost considerations, and production volume. Common PCB materials include FR-4 (Fire Retardant 4), flexible polyimide, and high-frequency laminates, each offering specific properties suited to different applications.

Key Factors in PCB Material Selection

Several key factors influence the selection of PCB materials, including electrical properties, thermal characteristics, mechanical strength, dimensional stability, and environmental considerations. For example, high-frequency applications may require PCB materials with low dielectric constant and loss tangent to minimize signal attenuation. Thermal management applications may necessitate PCB materials with high thermal conductivity and low coefficient of thermal expansion (CTE) to dissipate heat effectively and minimize thermal stress. Additionally, considerations such as cost, availability, and compatibility with manufacturing processes also influence PCB material selection decisions.

Overview of PCB Manufacturing Processes

The manufacturing of PCBs involves several sequential processes, including substrate preparation, circuit layout and design, imaging, etching, drilling, plating, solder mask application, and surface finishing. These processes are carried out using a combination of automated machinery, chemical treatments, and inspection techniques to ensure the accurate fabrication of complex electronic circuits. Advanced manufacturing technologies, such as additive manufacturing (3D printing) and laser processing, are also increasingly employed to enhance the efficiency, precision, and flexibility of PCB production.

Heat Dissipation Applications of Electronic Substrates

Effective heat dissipation is critical for maintaining the performance, reliability, and longevity of electronic devices, particularly in high-power and high-frequency applications. Electronic substrates play a key role in heat management by providing thermal pathways for dissipating heat generated by semiconductor components. One such technology is Active Metal Brazed (AMB) substrate cooling, which utilizes active metal brazing techniques to join ceramic substrates with metal layers, creating efficient heat transfer paths. AMB substrate cooling enhances thermal conductivity and reliability, enabling the effective removal of heat from electronic devices and ensuring optimal performance under demanding operating conditions.

Introduction to AMB Substrate Cooling Technology

AMB substrate cooling technology employs active metal brazing techniques to bond ceramic substrates with metal layers, creating robust thermal interfaces capable of efficiently dissipating heat from electronic components. The active metal brazing process involves heating the substrate assembly in a controlled atmosphere, causing the brazing material to melt and form a metallurgical bond between the ceramic and metal layers. This bonded structure enhances thermal conductivity, enabling the rapid transfer of heat away from semiconductor devices to external heat sinks or cooling systems. AMB substrate cooling technology is widely used in power electronics, RF/microwave applications, and other high-temperature environments where effective heat dissipation is essential for device performance and reliability.

Heat Dissipation Challenges and Solutions in Electronic Devices

Electronic devices face numerous challenges related to heat dissipation, including thermal resistance, thermal cycling, hot spots, and thermal management in confined spaces. These challenges can lead to performance degradation, reliability issues, and premature failure of electronic components. To address these challenges, engineers employ various heat dissipation solutions, including passive cooling methods (e.g., heat sinks, thermal vias, thermal pads) and active cooling techniques (e.g., fans, liquid cooling, thermoelectric coolers). Additionally, advanced substrate materials and cooling technologies, such as AMB substrate cooling, are continuously developed to improve thermal performance and address evolving heat dissipation requirements in electronic devices.

FAQs About Electronic Substrate

In electronics, a substrate refers to a material layer or base upon which electronic components are mounted and interconnected to form functional circuits. It provides mechanical support and electrical connectivity for the components, facilitating their integration into electronic devices.

Electronic substrates can be made from various materials depending on the specific application requirements. Common materials include fiberglass-reinforced epoxy, polyimide, ceramics such as alumina or aluminum nitride, and metals like copper. The choice of substrate material depends on factors such as electrical properties, thermal conductivity, mechanical strength, and cost-effectiveness.

In engineering, a substrate generally refers to a base or underlying material upon which other materials or components are deposited, attached, or integrated to form a functional structure or device. It serves as a foundation or support for the fabrication or assembly of various engineering systems, ranging from electronic circuits to semiconductor devices to chemical reactors.

A PCB (Printed Circuit Board) substrate is a type of electronic substrate specifically designed for the fabrication of printed circuit boards. It typically consists of a thin layer of non-conductive material, such as fiberglass-reinforced epoxy (FR-4), with conductive traces, pads, and vias patterned onto its surface. PCB substrates provide the structural support and electrical connectivity necessary for mounting and interconnecting electronic components, enabling the creation of complex electronic circuits in a compact and reliable format.