Flexible Substrates: Enabling Bendable PCBs

Flexible electronics, an innovative field at the intersection of materials science and electronics, promises to revolutionize the way we interact with technology. At its core lies the concept of creating electronic devices that can bend, stretch, and conform to various surfaces. Flexible substrates, essential components of these devices, play a pivotal role in enabling their functionality. These substrates provide the necessary support and flexibility for electronic components, allowing them to maintain performance even under dynamic conditions. The significance of flexible substrates in the electronics industry cannot be overstated, as they unlock new possibilities for wearable devices, foldable displays, and biomedical sensors. As research and development in flexible electronics continue to advance, understanding the fundamentals of flexible substrates becomes increasingly crucial for realizing the full potential of this transformative technology.

Types of Flexible Substrates

Flexible substrates come in various forms, each with unique properties and applications. Here, we explore three major types:

Polyethylene Terephthalate (PET) Substrates

PET substrates are widely used in flexible electronics due to their excellent mechanical properties and cost-effectiveness. These substrates consist of a thin, transparent plastic film composed of polyethylene terephthalate molecules. The molecular structure of PET provides flexibility while maintaining strength and dimensional stability. PET substrates are commonly found in applications such as:

- Flexible displays: PET films serve as the base material for manufacturing flexible OLED and LCD displays used in smartphones, tablets, and wearable devices.

- Flexible printed circuit boards (PCBs): PET substrates provide a durable and flexible platform for mounting electronic components in various applications, including automotive interiors and medical devices.

Polyimide (PI) Substrates

PI substrates are renowned for their exceptional thermal stability, chemical resistance, and mechanical flexibility. These substrates are composed of polyimide polymers, which exhibit high heat resistance and low thermal expansion coefficients. PI substrates find extensive use in applications where high temperature and harsh environments are prevalent. Some examples include:

- Flexible circuits: PI substrates are used as the base material for manufacturing flexible PCBs, which are employed in aerospace, military, and automotive industries due to their resilience to extreme conditions.

- Flexible heaters: PI films serve as the substrate for flexible heating elements used in medical devices, aerospace applications, and consumer electronics.

Polyether Ether Ketone (PEEK) Substrates

PEEK substrates offer a unique combination of mechanical strength, chemical resistance, and biocompatibility. These substrates are composed of polyether ether ketone polymer chains, which provide excellent toughness and dimensional stability. PEEK substrates are increasingly being utilized in demanding applications requiring robust performance. Some examples include:

- Biomedical implants: PEEK substrates are used in orthopedic implants, dental devices, and spinal implants due to their biocompatibility and resistance to bodily fluids.

- Aerospace components: PEEK substrates are employed in aircraft interiors, structural components, and electrical connectors due to their lightweight nature and resistance to aviation fuels and lubricants.

Each type of flexible substrate offers unique advantages and applications, contributing to the versatility and adaptability of flexible electronics in various industries.

Applications of Flexible Substrates in Electronics

Flexible substrates serve as the backbone for a diverse range of electronic products, enabling innovative solutions across various industries. Below, we delve into some prominent applications of flexible substrates:

Overview of Flexible Electronic Products

Flexible electronics encompass a broad spectrum of products that leverage the flexibility and lightweight nature of substrates like PET, PI, and PEEK. These products include wearable devices, smart textiles, bendable gadgets, and rollable displays, among others. The flexibility of substrates enables the creation of electronics that conform to the body, adapt to irregular shapes, and withstand bending and folding.

Flexible Displays

Flexible displays represent one of the most prominent applications of flexible substrates. OLED (Organic Light Emitting Diode) and LCD (Liquid Crystal Display) technologies utilize flexible substrates such as PET and PI to create bendable and rollable screens. These displays are increasingly being integrated into smartphones, tablets, smartwatches, and automotive dashboards, offering enhanced durability and portability compared to traditional rigid displays.

Flexible Sensors

Flexible substrates facilitate the development of flexible sensor technologies that can conform to curved surfaces and irregular shapes. These sensors, including pressure sensors, temperature sensors, and biosensors, find applications in healthcare, robotics, automotive, and consumer electronics. For example, flexible pressure sensors embedded in wearable devices can monitor vital signs or detect touch interactions on flexible surfaces.

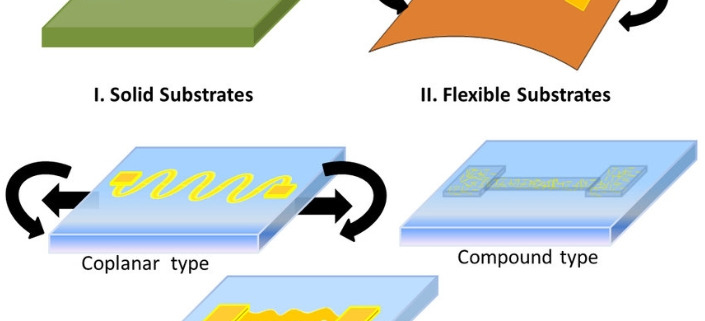

Flexible PCBs (Printed Circuit Boards) and Circuit Layouts

Flexible PCBs, also known as flex circuits, utilize flexible substrates to interconnect electronic components in devices where traditional rigid PCBs are impractical. These circuits can bend, fold, or twist to fit into tight spaces or conform to complex geometries. Flexible PCBs are widely used in automotive systems, medical devices, aerospace applications, and consumer electronics, offering improved reliability and space-saving advantages.

Flexible Solar Cells

Flexible substrates play a crucial role in the development of lightweight and portable solar cells. These cells, often based on thin-film photovoltaic technologies, can be integrated into flexible substrates to create flexible and lightweight solar panels. Flexible solar cells find applications in remote power generation, portable electronics charging, and building-integrated photovoltaics (BIPV), where traditional rigid solar panels are unsuitable or impractical.

Flexible substrates enable the realization of a wide range of innovative electronic products, including displays, sensors, PCBs, and solar cells, by providing the necessary flexibility, durability, and adaptability to meet the evolving needs of modern technology.

Advantages and Challenges of Flexible Substrates

Flexible substrates offer a host of advantages that make them highly desirable for a wide range of applications. However, they also present certain challenges that need to be addressed for widespread adoption. Let’s delve deeper into the advantages and challenges:

Advantages

Bendable, Rollable, Foldable

Flexible substrates such as PET, PI, and PEEK allow electronic devices to bend, roll, or fold without compromising functionality. This flexibility opens up new possibilities for innovative product designs, such as foldable smartphones, rollable displays, and wearable electronics. The ability to conform to different shapes enhances user experience and expands the potential applications of electronic devices.

Lightweight and Thin

Flexible substrates are inherently lightweight and thin, offering significant advantages in terms of portability and weight reduction. Compared to traditional rigid substrates, flexible substrates contribute to the development of lighter and more compact electronic products. This is particularly beneficial for portable devices, aerospace applications, and wearable technology, where weight and size constraints are critical factors.

Adaptability to Complex Shapes

Flexible substrates can adapt to complex and irregular shapes, allowing electronic components to be integrated seamlessly into various form factors. This adaptability enables the creation of electronics for curved surfaces, flexible displays, and unconventional product designs. Flexible substrates empower designers to explore new avenues of creativity and innovation in product development.

Challenges

High Manufacturing Costs

The manufacturing processes involved in producing flexible substrates can be more complex and costly compared to traditional rigid substrates. Specialized equipment and materials are often required to achieve the desired flexibility and performance characteristics, leading to higher production expenses. As a result, the cost of flexible electronics may be higher initially, posing a barrier to widespread adoption.

Technical Performance Limitations

While flexible substrates offer unique advantages, they may also have certain limitations in terms of technical performance. For example, flexible substrates may have lower heat dissipation capabilities compared to rigid substrates, which can affect the performance and longevity of electronic components. Additionally, the mechanical properties of flexible substrates, such as tensile strength and elongation, may impose constraints on the design and functionality of electronic devices.

Reliability and Stability Issues

Flexible substrates may be susceptible to reliability and stability issues over time, particularly under harsh environmental conditions or repeated bending cycles. Factors such as material degradation, fatigue failure, and moisture absorption can affect the long-term reliability of flexible electronic devices. Ensuring the durability and stability of flexible substrates requires thorough testing, quality control measures, and the development of robust materials and manufacturing processes.

While flexible substrates offer numerous advantages in terms of flexibility, lightweight construction, and adaptability, they also present challenges related to manufacturing costs, technical performance, and reliability. Addressing these challenges through research, innovation, and advancements in materials science and manufacturing technologies will be crucial for unlocking the full potential of flexible electronics in various industries.

Future Trends in Flexible Substrates

The future of flexible substrates holds great promise, with ongoing research and development aimed at addressing current challenges and unlocking new opportunities. Here are some key trends shaping the future of flexible substrates:

Development and Application of New Materials: Innovations in materials science are driving the development of advanced flexible substrates with enhanced properties and functionalities. Researchers are exploring novel materials and composites that offer improved flexibility, durability, and performance for flexible electronics applications. These materials may include advanced polymers, nanomaterials, and hybrid materials engineered to meet the specific requirements of different applications. For example, bio-based and environmentally friendly materials are gaining traction for sustainable flexible electronics.

Improvement of Manufacturing Processes: Advancements in manufacturing processes are essential for scaling up the production of flexible substrates and reducing manufacturing costs. Researchers and industry stakeholders are exploring innovative fabrication techniques such as roll-to-roll manufacturing, printing technologies, and additive manufacturing to achieve high throughput and cost-effective production of flexible substrates. Process optimization, automation, and integration of digital technologies are also driving efficiency gains in flexible substrate manufacturing.

Expansion and Innovation in Application Areas: The application areas for flexible substrates are expanding beyond traditional consumer electronics to include healthcare, automotive, aerospace, and energy sectors. In healthcare, flexible substrates are enabling the development of wearable health monitors, smart textiles, and implantable medical devices that conform to the body and provide continuous monitoring and treatment. In automotive and aerospace industries, flexible substrates are being used in interior lighting, cockpit displays, and structural components to reduce weight and enhance design flexibility. Furthermore, the integration of flexible substrates into energy applications such as flexible solar panels, energy harvesting devices, and flexible batteries is paving the way for advancements in renewable energy generation and storage.

Emerging Trends: Several emerging trends are poised to shape the future landscape of flexible substrates. These include the integration of flexible electronics with Internet of Things (IoT) technologies, artificial intelligence (AI), and augmented reality (AR) to create smart, interconnected systems. Additionally, the rise of flexible hybrid electronics, which combine flexible substrates with traditional rigid components, is opening up new possibilities for multifunctional devices with enhanced capabilities.

The future of flexible substrates is characterized by continuous innovation in materials, manufacturing processes, and application areas. By addressing technical challenges and embracing emerging trends, flexible substrates are poised to play a pivotal role in the next generation of electronic devices and systems, driving advancements in technology, healthcare, transportation, and energy.

FAQs About Flexible Substrate

Flexible substrate for PCB (Printed Circuit Board) refers to a material that provides a flexible base for mounting electronic components and creating electrical connections. Unlike traditional rigid substrates such as fiberglass, flexible PCB substrates are made from flexible materials like polyimide (PI) or polyester (PET). These substrates allow the PCB to bend, twist, or fold to fit into tight spaces or conform to the shape of the device.

1.Polyethylene Terephthalate (PET): PET substrates are lightweight, transparent, and cost-effective. They are commonly used in applications such as flexible displays, sensors, and RFID tags.

2.Polyimide (PI): PI substrates offer excellent thermal stability, chemical resistance, and flexibility. They are widely used in high-temperature applications, such as aerospace, automotive, and medical devices.

3.Polyether Ether Ketone (PEEK): PEEK substrates combine mechanical strength, chemical resistance, and biocompatibility. They are used in demanding applications such as biomedical implants, aerospace components, and electrical connectors.

Flexible electronics refers to electronic devices and systems that are made using flexible materials and substrates, allowing them to bend, stretch, or conform to various shapes. These devices often utilize flexible substrates such as polyimide or polyester and can include components such as flexible displays, sensors, batteries, and circuits. Flexible electronics enable the development of lightweight, portable, and wearable devices with enhanced flexibility and adaptability, opening up new possibilities for applications in healthcare, consumer electronics, automotive, and beyond.