Soldering mask pcb uses, materials, and process guide

If you’ve ever taken a close look at a printed circuit board (PCB), you’ve probably noticed the smooth, colored coating covering most of the copper traces. That layer is called the solder mask (also known as solder resist), and it’s one of the unsung heroes of PCB manufacturing.

Without solder mask, PCBs would be far more vulnerable to short circuits, corrosion, and handling damage. It’s not just cosmetic — the solder mask plays a critical role in ensuring long-term reliability, high manufacturing yields, and stable electrical performance.

Before we dive in, let’s clear one point: the “mask” we’re discussing here is part of the PCB itself, not the respirator mask you might wear for safety when soldering.

What is a Solder Mask in PCB?

The solder mask is a thin polymer layer that covers and protects the copper surfaces of a PCB except where components need to be soldered.

It is applied during the fabrication process and is carefully patterned to expose only the pads where solder joints will be made. In PCB design files, the solder mask layer is defined in the Gerber files — this tells the fabricator exactly where openings should be made.

Key functions:

-

Prevent solder bridges between closely spaced pads

-

Protect copper from oxidation and contamination

-

Provide electrical insulation

-

Improve the PCB’s mechanical durability

Solder Mask Uses in PCBs

In practical terms, solder mask serves several purposes:

-

Preventing solder shorts – During reflow or wave soldering, solder can accidentally form bridges between pads. The mask creates physical separation.

-

Environmental protection – Shields copper from moisture, dust, and chemicals.

-

Mechanical wear resistance – Prevents abrasion of delicate copper traces.

-

Aesthetic enhancement – Gives PCBs a professional, finished look and aids in assembly alignment.

-

Improved inspection – Certain colors (like green) offer better contrast under optical inspection.

PCB Solder Mask Materials

Solder mask materials are chosen for chemical resistance, thermal stability, and strong adhesion to copper and laminate.

Common types:

-

Epoxy Liquid – Low-cost, thermosetting polymers, screen printed.

-

Liquid Photoimageable (LPI) Solder Mask – Most common today, applied by spray or curtain coat, patterned by UV exposure.

-

Dry Film Solder Mask – Laminated as a film, often used for high-density PCBs.

Typical properties:

-

High temperature resistance (>150°C) for lead-free soldering

-

Chemical stability against fluxes and cleaning agents

-

Dielectric strength for insulation

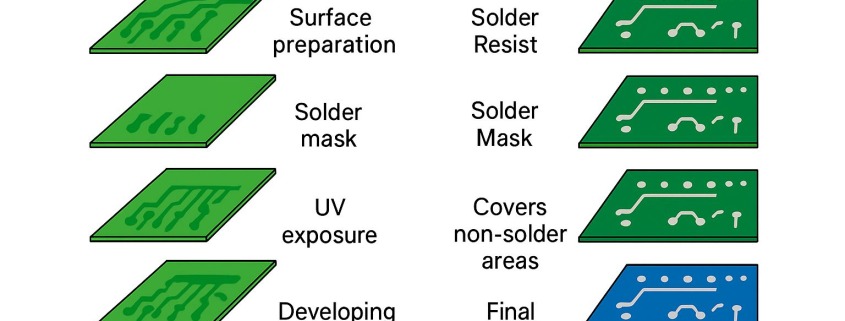

PCB Solder Mask Process

The manufacturing process for solder mask is precise and multi-step:

-

Surface preparation – PCB panels are cleaned and micro-etched for better adhesion.

-

Coating – LPI solder mask is applied via spray or curtain coating; dry film is laminated under heat and pressure.

-

Pre-bake – Partially cures the coating to remove solvents.

-

UV Exposure – A phototool defines where solder mask remains; exposed areas harden.

-

Developing – Unexposed areas are washed away, revealing pads.

-

Final Curing – Thermal or UV curing for full hardness.

Quality checks: Thickness uniformity, registration accuracy, adhesion strength, and absence of pinholes.

Solder Resist vs. Solder Mask

These terms are often used interchangeably:

-

Solder resist refers to the property of preventing solder from adhering to certain areas.

-

Solder mask refers to the physical layer that provides this resistance.

In practice, most engineers simply say “solder mask.”

Solder Mask Openings in PCB

A solder mask opening is an exposed copper area designed for soldering — typically component pads, test pads, or vias.

Design considerations:

-

Tolerance – Too small and it may partially cover the pad; too large and it risks solder bridging.

-

Registration – Fabricators must align openings precisely with the copper layer.

-

Special cases – Tented vias (covered with mask) to prevent solder wicking.

Solder Mask Paste – Not the Same Thing

This is a common beginner’s misunderstanding:

-

Solder paste is a mix of powdered solder and flux used to form solder joints.

-

Solder mask is a permanent protective coating.

They serve completely different purposes and are applied at different stages.

Which Color of Solder Mask is Used on PCBs?

While green is the industry default — largely for historical and optical inspection reasons — other colors are available:

-

Red, Blue, Black – Common for branding or visual distinction.

-

White – Often used for LED lighting PCBs (high reflectivity).

-

Yellow – Less common, but used for specialty boards.

Different colors can have varying levels of transparency, heat resistance, and UV stability. Some high-end products choose custom colors for brand identity.

Should You Use a Mask When Soldering?

Here, “mask” means personal protective equipment. While not mandatory for all soldering, it’s recommended when:

-

Using lead-based solder (to avoid inhaling lead particles and flux fumes)

-

Working in poorly ventilated areas

-

Soldering for extended periods

Alternatives include fume extractors or working near an open window.

Is Solder Mask the Same as Conformal Coating?

No — they are different protective layers:

-

Solder mask: Applied during PCB fabrication, covers copper traces.

-

Conformal coating: Applied after assembly, coats the entire board and components for environmental protection (e.g., humidity, chemicals).

Some ruggedized electronics use both for maximum protection.