Top PCB Substrate Manufacturers

PCB substrates serve as the foundation for electronic components in printed circuit boards (PCBs), providing mechanical support and electrical insulation. Selecting the appropriate substrate is paramount, as it directly impacts the performance, reliability, and longevity of electronic devices. With a myriad of substrate materials available, such as FR-4, ceramic, and flexible materials, understanding their properties and suitability for specific applications is crucial. This guide offers an in-depth exploration of PCB substrate manufacturers, detailing their product offerings, manufacturing processes, and industry standing. By delving into the intricacies of substrate selection and the capabilities of leading manufacturers, readers can make informed decisions to optimize their PCB designs and enhance overall product quality and performance.

Understanding PCB Substrates

Definition and Role of Substrate in PCBs: PCB substrates are the foundational materials upon which electronic components are mounted and interconnected to form a functional circuit. They provide mechanical support, electrical insulation, and a stable platform for component placement. The substrate acts as a dielectric layer between the conductive traces, ensuring proper signal transmission and preventing short circuits.

Factors Influencing Substrate Selection: Several factors influence the selection of PCB substrates, including:

- Operating environment (temperature, humidity, chemical exposure)

- Electrical performance requirements (dielectric constant, impedance)

- Mechanical properties (flexibility, rigidity, dimensional stability)

- Cost considerations

- Manufacturing processes compatibility

- End-application requirements (high frequency, high power, reliability)

Common Materials Used for PCB Substrates

- FR-4 (Flame Retardant-4):

- Most widely used substrate material for rigid PCBs

- Composed of woven fiberglass cloth impregnated with epoxy resin

- Offers excellent electrical insulation and mechanical strength

- Cost-effective and readily available

- Suitable for a wide range of applications, including consumer electronics, telecommunications, and industrial equipment

- Ceramic:

- Ideal for high-frequency and high-power applications

- Offers superior thermal conductivity and stability

- Provides excellent electrical insulation and mechanical strength

- Suitable for harsh environments and extreme operating conditions

- Commonly used in aerospace, automotive, and military applications

- Flexible Materials:

- Comprised of thin, flexible substrates such as polyimide or polyester

- Allows for bending and flexing of the PCB, enabling compact designs and intricate layouts

- Ideal for applications requiring lightweight and space-saving solutions, such as wearable devices, medical implants, and flexible displays

- Metal Core:

- Consists of a metal base layer (e.g., aluminum or copper) sandwiched between dielectric layers

- Offers enhanced thermal conductivity, making it suitable for dissipating heat in high-power applications

- Provides excellent mechanical stability and rigidity

- Commonly used in LED lighting, automotive lighting, and power electronics

Comparison of Substrate Types: Advantages and Disadvantages

- FR-4:

- Advantages: Cost-effective, widely available, good electrical insulation.

- Disadvantages: Limited thermal conductivity, not suitable for high-power applications.

- Ceramic:

- Advantages: High thermal conductivity, excellent electrical properties, suitable for harsh environments.

- Disadvantages: Higher cost, brittle nature, limited flexibility.

- Flexible Materials:

- Advantages: Flexibility, lightweight, space-saving, suitable for dynamic applications.

- Disadvantages: Limited mechanical strength, higher cost compared to rigid substrates.

- Metal Core:

- Advantages: Excellent thermal conductivity, mechanical stability, suitable for high-power applications.

- Disadvantages: Higher cost, limited flexibility compared to flexible substrates.

Understanding the strengths and limitations of each substrate type is essential for selecting the most appropriate material to meet the specific requirements of a PCB design and its intended applica

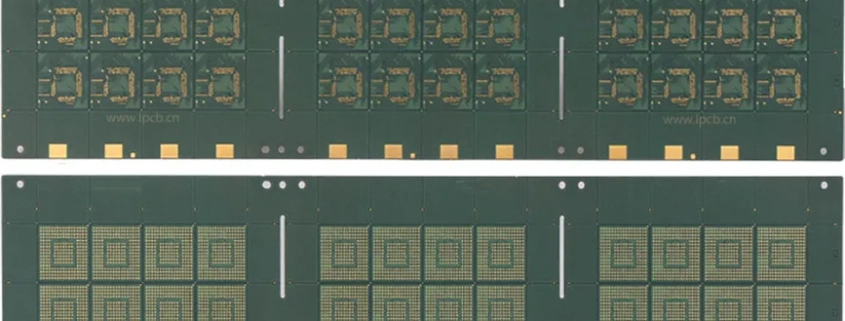

Top PCB Substrate Manufacturers

Overview of Prominent PCB Substrate Manufacturers Worldwide: The global market for PCB substrates is dominated by several key players known for their high-quality products, advanced manufacturing capabilities, and industry reputation. These manufacturers cater to diverse industries, including consumer electronics, automotive, aerospace, telecommunications, and more.

Company Profiles:

- Nippon Mektron (Japan):

- Product Offerings: Nippon Mektron offers a wide range of PCB substrates, including FR-4, flexible materials, and metal core boards. They specialize in high-density interconnect (HDI) PCBs for advanced electronic applications.

- Manufacturing Capabilities: With state-of-the-art facilities and advanced manufacturing processes, Nippon Mektron delivers high-quality PCB substrates with precision and reliability.

- Industry Reputation: Nippon Mektron is renowned for its commitment to innovation, quality, and customer satisfaction, earning a strong reputation as a trusted supplier in the PCB industry.

- Samsung Electro-Mechanics (South Korea):

- Product Offerings: Samsung Electro-Mechanics offers a comprehensive portfolio of PCB substrates, including high-performance FR-4, ceramic, and flexible materials. They also provide specialized solutions for emerging technologies such as 5G and IoT.

- Manufacturing Capabilities: Leveraging advanced manufacturing technologies and rigorous quality control processes, Samsung Electro-Mechanics ensures the highest standards of product quality and reliability.

- Industry Reputation: Samsung Electro-Mechanics is recognized for its technological expertise, product innovation, and commitment to sustainability, earning accolades as one of the top PCB substrate manufacturers globally.

- TTM Technologies (United States):

- Product Offerings: TTM Technologies offers a diverse range of PCB substrates, including FR-4, high-frequency laminates, and metal core boards. They specialize in complex multilayer PCBs for high-speed digital and RF applications.

- Manufacturing Capabilities: With advanced manufacturing facilities and a focus on process optimization, TTM Technologies delivers high-quality PCB substrates with fast turnaround times and competitive pricing.

- Industry Reputation: TTM Technologies is highly regarded for its technical expertise, customer-centric approach, and commitment to continuous improvement, earning the trust of leading companies in various industries.

- ALCANTAPCB Company Introduction:

- Product Offerings: ALCANTAPCB is a leading PCB substrate manufacturer, offering a diverse range of substrates including FR-4, ceramic, and flexible materials. Specializing in high-performance PCBs, they provide solutions for various industries such as telecommunications, automotive, and consumer electronics.

- Manufacturing Capabilities: Equipped with state-of-the-art facilities and expertise in advanced manufacturing processes, ALCANTAPCB excels in producing high-quality PCB substrates with precise specifications and quick turnaround times. Their focus on process optimization ensures efficient production and competitive pricing.

- Industry Reputation: ALCANTAPCB is highly esteemed for its technical innovation, reliability, and customer-centric approach. With a commitment to excellence, they have established themselves as a trusted partner for leading OEMs and electronics manufacturers worldwide, delivering superior products and exceptional service.

Manufacturing Process of PCB Substrates

Step-by-Step Explanation of PCB Substrate Manufacturing Process

1. Material Selection and Preparation

- The manufacturing process begins with the selection of suitable substrate materials based on the desired electrical, mechanical, and thermal properties.

- Raw materials, such as fiberglass cloth, epoxy resin, ceramic powders, or flexible substrates, are sourced from trusted suppliers and undergo thorough quality testing.

- Materials are then prepared for further processing, which may include cutting, cleaning, and surface treatment to ensure uniformity and purity.

2. Substrate Fabrication

a. FR-4 (Flame Retardant-4): Lamination Process

- Layers of fiberglass cloth are impregnated with epoxy resin to form prepreg sheets.

- Copper foil sheets, containing circuit patterns, are laminated onto the prepreg layers using heat and pressure.

- The laminated stack is then subjected to a curing process, where the resin is hardened to bond the layers together, forming a solid substrate with embedded copper traces.

b. Ceramic: Sintering Process

- Ceramic powders are mixed with binders and additives to form a slurry or paste.

- The paste is then deposited onto a substrate surface or molded into desired shapes using various techniques such as screen printing or injection molding.

- The green ceramic parts are subjected to a sintering process at high temperatures, where the particles fuse together to form a dense, solid structure with excellent mechanical and electrical properties.

c. Flexible Materials: Deposition and Curing

- Thin, flexible substrate materials such as polyimide or polyester films are coated with adhesive layers or conductive films using deposition techniques like sputtering or vapor deposition.

- The coated films are then cured or treated to enhance adhesion and mechanical strength, creating flexible substrates suitable for bending and folding in electronic devices.

d. Metal Core: Dielectric Bonding

- A metal core, typically aluminum or copper, is sandwiched between layers of dielectric material, such as FR-4 or thermally conductive epoxy.

- The layers are bonded together using heat and pressure, forming a solid structure with good thermal conductivity and mechanical stability, ideal for dissipating heat in high-power applications.

3. Surface Treatment and Finishing

- After substrate fabrication, surfaces may undergo treatment processes such as chemical etching, plasma cleaning, or mechanical polishing to remove contaminants and improve surface adhesion.

- Surface finishes, including solder mask application, surface plating, and metal deposition, are applied to protect exposed copper traces, enhance solderability, and improve electrical performance.

4. Quality Control and Testing

- Throughout the manufacturing process, stringent quality control measures are implemented to ensure the integrity and reliability of PCB substrates.

- Quality checks may include dimensional inspection, visual inspection, electrical testing, and reliability testing under simulated operating conditions.

- Defective substrates are identified and rectified or rejected to maintain product quality standards and customer satisfaction.

Advancements in PCB Substrate Manufacturing

Recent Innovations and Trends in PCB Substrate Technology

- High-Frequency Materials: With the increasing demand for high-speed data transmission in 5G networks and IoT devices, there is a growing need for PCB substrates with enhanced high-frequency performance. Manufacturers are developing specialized materials with low dielectric loss and controlled impedance to support high-frequency applications.

- Thermal Management Solutions: As electronic devices continue to shrink in size and increase in power density, effective thermal management becomes critical to prevent overheating and ensure reliable operation. Advanced PCB substrate materials with improved thermal conductivity and heat dissipation properties are being developed to address these challenges.

- Miniaturization and HDI Technology: The trend towards smaller, more compact electronic devices drives the demand for PCB substrates with higher wiring density and finer features. High-Density Interconnect (HDI) technology, including microvia and sequential lamination techniques, allows for the integration of more components and routing channels in a smaller footprint, leading to enhanced functionality and performance.

- Flexible and Stretchable Substrates: With the rise of wearable electronics, flexible and stretchable substrates are gaining traction in the industry. Researchers are exploring novel materials such as elastomers and conductive polymers to develop substrates that can conform to irregular shapes and withstand repeated bending and stretching without compromising electrical performance.

Emerging Materials and Techniques

- Organic Electronics: Organic substrates made from carbon-based polymers offer the potential for lightweight, flexible, and environmentally friendly alternatives to traditional rigid substrates. Researchers are investigating organic materials with tunable electrical properties and biodegradable characteristics for sustainable electronics applications.

- Nanotechnology: Nanomaterials, such as graphene and carbon nanotubes, hold promise for revolutionizing PCB substrate technology. These materials exhibit exceptional electrical, thermal, and mechanical properties, paving the way for ultra-thin, lightweight substrates with superior performance and durability.

- 3D Printing/Additive Manufacturing: Additive manufacturing techniques, such as 3D printing, enable the rapid prototyping and fabrication of complex PCB substrates with customized designs and geometries. Manufacturers are exploring the use of additive manufacturing to produce multi-material substrates with embedded components and integrated cooling channels for optimized functionality and performance.

- Bioinspired Materials: Drawing inspiration from nature, researchers are exploring bioinspired materials and fabrication techniques to develop PCB substrates with self-healing, self-cleaning, and adaptive properties. By mimicking biological systems, such as the hierarchical structure of natural materials or the self-repair mechanisms found in living organisms, bioinspired substrates hold the potential to enhance the resilience and longevity of electronic devices.

Global PCB Manufacturing Landscape

Overview of Countries Leading in PCB Manufacturing

- China: China has emerged as the world’s largest PCB manufacturing hub, driven by its vast industrial base, skilled workforce, and competitive manufacturing capabilities. The country accounts for a significant share of global PCB production, serving both domestic and international markets.

- Japan: Japan is renowned for its technological expertise and innovation in PCB manufacturing. Japanese companies excel in producing high-quality, high-density PCBs for a wide range of applications, including automotive, consumer electronics, and industrial equipment.

- Taiwan: Taiwan is a major player in the global PCB industry, particularly in the production of high-end PCBs and advanced technologies such as HDI and flexible substrates. Taiwanese manufacturers leverage their proximity to semiconductor and electronics supply chains to deliver cutting-edge PCB solutions.

- South Korea: South Korea boasts a strong presence in the PCB market, with leading companies specializing in advanced PCB technologies and materials. The country’s focus on research and development, coupled with strategic partnerships with global electronics giants, positions it as a key player in the industry.

Analysis of Market Share and Production Volume

- China dominates the global PCB market in terms of production volume, accounting for a significant portion of total PCB output worldwide. The country’s large-scale manufacturing facilities and cost-effective production capabilities contribute to its leading market position.

- Japan and South Korea command a substantial share of the global PCB market, driven by their specialization in high-quality, high-value-added PCBs for various industries. These countries focus on niche markets and advanced technologies to maintain their competitive edge.

- Taiwan’s PCB industry plays a crucial role in the global supply chain, particularly in the production of advanced PCBs for smartphones, tablets, and other consumer electronics. Taiwanese manufacturers prioritize innovation and efficiency to remain competitive in the global market.

Role of Key Players in Shaping the Industry

- Key players in the PCB industry, such as Nippon Mektron, Samsung Electro-Mechanics, and TTM Technologies, play a pivotal role in shaping industry trends and standards. These companies drive innovation, invest in research and development, and collaborate with customers to develop cutting-edge PCB solutions.

- Strategic partnerships and collaborations between PCB manufacturers and leading electronics companies influence product development and market trends. By working closely with OEMs and semiconductor manufacturers, PCB suppliers can anticipate market demands and develop customized solutions to meet specific requirements.

- Environmental sustainability and regulatory compliance are increasingly important considerations for PCB manufacturers. Leading players in the industry are adopting green manufacturing practices, reducing waste, and adhering to stringent environmental regulations to minimize their ecological footprint and enhance corporate responsibility.

FAQs About PCB Substrate Manufacturer

The best substrate for a PCB depends on various factors such as the application, operating environment, and performance requirements. Common substrates include FR-4, ceramic, flexible materials, and metal core boards.

PCBs are manufactured by a wide range of companies worldwide, including large-scale manufacturers such as Nippon Mektron, Samsung Electro-Mechanics, TTM Technologies, and many others.

PCB substrates are made through processes such as material selection, preparation, substrate fabrication (including techniques like lamination for FR-4, sintering for ceramic, deposition and curing for flexible materials, and dielectric bonding for metal core), surface treatment, finishing, and quality control testing.

China is the largest manufacturer of PCBs globally, accounting for a significant portion of the total PCB production volume. Other major PCB manufacturing countries include Japan, Taiwan, and South Korea.