Rogers RO3003: Advancing Aerospace Communications

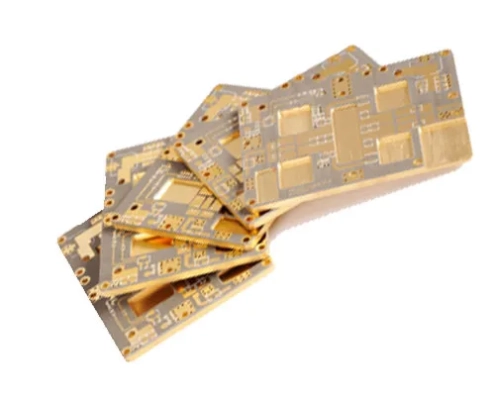

Rogers RO3003 is a high-frequency laminate that plays a pivotal role in the electronics industry. With its exceptional electrical properties and reliability, RO3003 is widely utilized in various applications demanding precise signal integrity and high-frequency performance. As the demand for faster and more efficient electronic devices continues to surge, RO3003 emerges as a fundamental component in RF and microwave circuit design. Its low loss tangent, consistent dielectric constant, and excellent dimensional stability make it indispensable for applications such as telecommunications, radar systems, satellite communication, and medical equipment. In this blog, we’ll delve deeper into the unique properties and versatile applications of Rogers RO3003, shedding light on its significance in advancing modern electronic technologies.

Overview of RO3003

Technical Specifications of RO3003

Technical Parameters and Performance Indicators: Rogers RO3003 boasts several key technical parameters and performance indicators that contribute to its exceptional performance in high-frequency applications:

- Dielectric Constant (εr): RO3003 typically exhibits a dielectric constant in the range of 3.0, which remains stable across a wide frequency range. This low dielectric constant ensures minimal signal loss and accurate signal propagation in high-frequency circuits.

- Loss Tangent (tanδ): With a low loss tangent of approximately 0.0013, RO3003 minimizes signal attenuation, ensuring high signal integrity and efficient transmission of microwave signals. The low loss tangent contributes to the high quality of signals in RF and microwave circuits.

- Copper Foil Thickness: The copper foil thickness in RO3003 laminate is typically specified in ounces per square foot (oz/ft²) or micrometers (µm). The thickness of the copper foil is crucial for achieving the desired impedance and ensuring good electrical performance in the circuit.

- Layer Thickness: RO3003 is available in various thicknesses, typically ranging from tens to hundreds of mils (thousandths of an inch). The layer thickness determines the overall thickness of the laminate, which affects its mechanical properties and impedance characteristics.

- Temperature Stability: RO3003 offers excellent thermal stability, with a low coefficient of thermal expansion (CTE). This ensures that the laminate maintains its dimensional stability and electrical properties over a wide temperature range, making it suitable for use in harsh environmental conditions.

Detailed Explanation of Parameters in the Datasheet

- Dielectric Constant (εr): The dielectric constant of RO3003 represents its ability to store electrical energy when subjected to an electric field. A low dielectric constant indicates minimal electrical energy storage and is desirable for high-frequency applications to minimize signal loss.

- Loss Tangent (tanδ): The loss tangent of RO3003 measures the ratio of energy lost as heat to the energy stored in the dielectric material. A low loss tangent signifies minimal signal attenuation, ensuring high signal integrity and efficient transmission of microwave signals.

- Copper Foil Thickness: The thickness of the copper foil in RO3003 affects the characteristic impedance of transmission lines and contributes to the overall electrical performance of the circuit. Thicker copper foils are typically used for higher power applications or when lower impedance lines are required.

- Layer Thickness: The layer thickness of RO3003 determines the overall thickness of the laminate and affects its mechanical properties, such as stiffness and flexibility. Thicker laminates may be preferred for applications requiring enhanced rigidity, while thinner laminates offer greater flexibility and space savings.

- Temperature Stability: The temperature stability of RO3003 is crucial for ensuring reliable performance in diverse operating conditions. A low coefficient of thermal expansion (CTE) indicates minimal dimensional changes with temperature, ensuring consistent electrical performance over a wide temperature range.

Applications of RO3003

Comparison with Other Rogers Laminates

Pricing and Availability of RO3003

Price Range and Availability: The pricing and availability of RO3003 laminate can vary depending on factors such as supplier, quantity, and geographic location. Generally, RO3003 is considered a premium-grade laminate due to its high-frequency performance and specialized composition. Here are some key points regarding its pricing and availability:

- Price Range: The price of RO3003 laminate typically ranges from several dollars per square foot for standard thicknesses to higher prices for customized specifications or specialty treatments. Prices may also vary based on volume discounts and supplier agreements.

- Availability: RO3003 laminate is widely available from authorized distributors, manufacturers, and specialty suppliers. Major electronics materials distributors often stock RO3003 along with other Rogers laminates to cater to the demand from various industries.

- Lead Time: The lead time for procuring RO3003 laminate can vary depending on the supplier’s inventory levels and manufacturing schedules. Standard configurations are usually readily available for immediate purchase, while customized or large-volume orders may require longer lead times.

Recommended Procurement Channels and Considerations: When sourcing RO3003 laminate, it’s essential to consider various factors to ensure optimal pricing, quality, and delivery. Here are some recommended procurement channels and considerations:

- Authorized Distributors: Procuring RO3003 laminate from authorized distributors ensures access to genuine products with manufacturer warranties and technical support. Authorized distributors often maintain a comprehensive inventory of Rogers laminates and offer competitive pricing.

- Direct Purchase from Manufacturers: For large-volume orders or customized requirements, direct purchase from the manufacturer may be advantageous. This allows for direct communication with the manufacturer to tailor specifications and negotiate pricing based on volume commitments.

- Considerations: When sourcing RO3003 laminate, it’s important to consider factors such as:

- Quality Assurance: Ensure that the laminate meets industry standards and specifications, and verify the authenticity of the product through proper documentation and traceability.

- Compliance: Confirm compliance with regulatory requirements and industry standards applicable to the intended application, such as IPC standards for PCB materials.

- Shipping and Logistics: Evaluate shipping options, transit times, and logistics considerations to minimize lead times and ensure timely delivery of materials.

Procuring RO3003 laminate involves assessing pricing, availability, and procurement channels to meet the specific requirements of the application. Working with authorized distributors or manufacturers and considering quality, compliance, and logistics factors can help ensure a smooth procurement process and optimal performance of the laminate in electronic designs.

Future Developments of RO3003

FAQs About Rogers RO3003

What is Rogers RO3003?

Rogers RO3003 is a high-frequency laminate material designed for RF and microwave applications, known for its exceptional electrical performance and reliability.

What are the key properties of RO3003?

RO3003 exhibits a low dielectric constant, low loss tangent, excellent dimensional stability, and smooth copper foil surface, making it ideal for high-frequency circuitry.

What applications is RO3003 suitable for?

RO3003 is used in telecommunications, aerospace, medical devices, automotive radar systems, and other applications requiring precise signal integrity at microwave frequencies.

How does RO3003 compare to other Rogers laminates like RO4003 and RO5880?

RO3003 offers lower dielectric constant and loss tangent compared to RO4003, making it suitable for applications demanding higher performance. RO3003 also differs from RO5880 in terms of dielectric constant and loss tangent, catering to different performance requirements.

What are the benefits of using RO3003 in high-frequency PCB designs?

RO3003 ensures minimal signal loss, accurate signal propagation, and reliable performance in high-speed communication networks and RF systems.

Can RO3003 withstand harsh environmental conditions?

Yes, RO3003 exhibits excellent thermal stability and mechanical strength, making it suitable for use in harsh operating environments encountered in aerospace, defense, and automotive applications.

Is RO3003 compatible with standard PCB fabrication processes?

Yes, RO3003 is compatible with standard fabrication processes including laser drilling, mechanical drilling, and photoimaging, simplifying manufacturing processes and reducing production costs.

Where can I purchase RO3003 laminate?

RO3003 laminate is available from authorized distributors, manufacturers, and specialty suppliers worldwide.

What factors should be considered when selecting RO3003 for a specific application?

Considerations include required electrical performance, environmental conditions, regulatory compliance, and procurement considerations such as pricing, availability, and lead time.

Are there any precautions to take when working with RO3003 laminate?

It’s important to handle RO3003 laminate with care to avoid damage to its electrical properties. Follow manufacturer guidelines for storage, handling, and fabrication processes to ensure optimal performance.