QFN Packages: Revolutionizing Electronics Miniaturization

Quantum Flat No-leads (QFN) packages, characterized by their leadless design and exposed thermal pad, play a crucial role in modern electronics. Their compact nature, enhanced thermal performance, and growing acceptance in the semiconductor industry make QFN packages a preferred choice for high-density and miniaturized electronic applications, showcasing their significance in advancing electronic packaging solutions.

Understanding QFN Packages

Definition of QFN

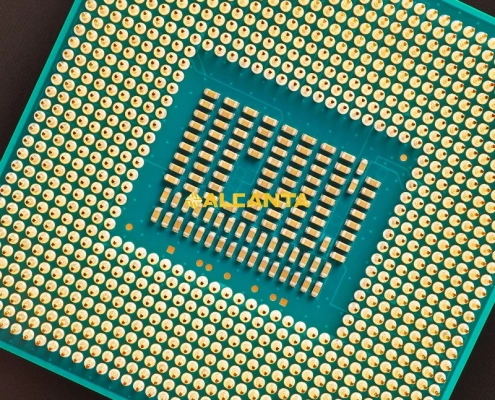

Quantum Flat No-leads (QFN) packages represent a category of surface-mount integrated circuit (IC) packaging known for their innovative leadless design. In these packages, an exposed thermal pad beneath the chip replaces traditional leads, enhancing thermal dissipation and electrical performance.

- QFN Expansion: The QFN expansion, “Quantum Flat No-leads,” emphasizes the package’s unique structure, devoid of conventional leads. This expansion underscores the advanced and space-efficient nature of QFN packages.

- QFN Abbreviation Explanation: Breaking down the abbreviation, “Q” signifies “Quantum,” highlighting the package’s modern design, while “FN” stands for “Flat No-leads,” emphasizing the absence of protruding leads in favor of a flat configuration.

QFN vs. QFP Packages

- Key Differences: QFN and Quad Flat Package (QFP) differ significantly in their design. QFP has leads surrounding all four sides, while QFN’s leadless design involves a flat pad beneath the chip. This distinction affects size, thermal performance, and manufacturing complexity.

- Advantages of QFN Over QFP: QFN offers advantages such as smaller form factor, improved thermal dissipation due to the exposed pad, and simplified manufacturing processes, making it more suitable for compact and high-performance electronic devices.

DFN vs. QFN Packages

- Comparison of DFN and QFN: QFN and Dual Flat No-leads (DFN) packages share similarities but differ in terms of lead configuration. QFN’s exposed thermal pad distinguishes it from DFN, contributing to variations in thermal management and electrical characteristics.

- Distinct Characteristics: QFN’s distinct features include its leadless design, compact footprint, and improved thermal performance, setting it apart from DFN and making it a preferred choice for certain applications where space and thermal considerations are critical.

Types and Sizes of QFN Packages

QFN Package Datasheet

QFN Package Soldering

Soldering Techniques for QFN Packages

Soldering QFN packages demands precision and adherence to specific techniques. Common methods include:

- Reflow Soldering: Utilizing controlled heating profiles to melt solder paste and attach the QFN to the PCB.

- Hand Soldering: Delicate manual soldering, suitable for prototypes or low-volume production.

- Infrared Soldering: Applying infrared radiation for focused and controlled heating during the soldering process.

Challenges and Solutions in QFN Soldering

- Thermal Imbalances: QFN’s exposed pad can lead to uneven heating. Solution: Implement a balanced thermal profile during reflow, utilizing proper equipment calibration.

- Solder Bridging: Close proximity of QFN leads may result in solder bridging. Solution: Optimize solder paste stencil design and use controlled solder dispensing techniques.

- Voiding: Air pockets in solder joints can compromise electrical and thermal performance. Solution: Employ vacuum reflow or nitrogen atmosphere during soldering to minimize void formation.

Best Practices for Soldering QFN Packages

- Stencil Design: Ensure precise and consistent solder paste deposition using an appropriately designed stencil.

- Component Placement: Accurate placement on the PCB is critical. Automated pick-and-place machines enhance precision.

- Reflow Profile Optimization: Tailor the reflow soldering profile to the specific QFN package, considering its size, thermal characteristics, and manufacturer recommendations.

- Inspect and Test: Implement thorough visual inspections and automated testing to identify and rectify soldering defects, ensuring high-quality connections.

- Training and Skill Development: Provide proper training to operators involved in the soldering process, emphasizing the intricacies of QFN soldering techniques.

Successful QFN soldering hinges on meticulous execution of these techniques, addressing challenges, and adhering to best practices, ultimately ensuring reliable and robust connections between QFN packages and PCBs.

QFN Package Process Flow

Manufacturing Process Overview

The manufacturing process of QFN packages involves several stages, starting from the fabrication of the leadframe or substrate to the final assembly and testing. The key steps include:

- Leadframe Fabrication: Creating the leadframe or substrate, often made of copper or other conductive materials, to serve as the foundation for the QFN package.

- Die Attach: Placing and bonding the semiconductor die onto the leadframe or substrate with conductive adhesive materials.

- Wire Bonding: Connecting the die to the leadframe by wire bonding, typically using gold or aluminum wires.

- Molding: Encapsulating the assembly in a protective mold compound to shield it from environmental factors and provide structural integrity.

- Lead Frame Singulation: Separating individual QFN packages from the leadframe.

Assembly Steps and Quality Control

Solder Paste Application: Applying solder paste to the exposed thermal pad of the QFN package.

- Pick-and-Place: Automated placement of QFN packages onto the PCB, aligning them accurately with solder pads.

- Reflow Soldering: Subjecting the assembled PCB to controlled heating to melt the solder and establish electrical connections.

- Cleaning: Removing excess flux and residues post-soldering to enhance reliability.

- Visual Inspection: Conducting visual inspections to identify any visible defects or anomalies.

- X-ray Inspection: Utilizing X-ray equipment to inspect hidden solder joints and internal structures.

Inspection and Testing in QFN Package Production

- Automated Optical Inspection (AOI): Employing AOI systems to scan for soldering defects, misalignment, or component damage.

- Functional Testing: Verifying the functionality of each QFN package through electrical testing, ensuring proper connections and performance.

- Thermal Cycling Tests: Subjecting QFN packages to thermal cycling to assess their reliability under varying temperature conditions.

- Quality Control Checks: Implementing stringent quality control measures to meet industry standards and specifications.

- Traceability: Ensuring traceability of each QFN package through serial numbers or barcodes for quality monitoring and post-production analysis.

A well-defined and controlled process flow, coupled with rigorous inspection and testing protocols, ensures the production of high-quality QFN packages with reliable performance and longevity in diverse electronic applications.

Advantages of QFN Packages

Compact Design and Space Efficiency

One of the primary advantages of QFN packages is their compact design, offering a significantly smaller footprint compared to traditional leaded packages. The absence of external leads allows for a more efficient use of space on the printed circuit board (PCB). This compactness is particularly crucial in modern electronics, where miniaturization is a key design consideration, enabling the development of smaller and more portable devices.

Improved Thermal Performance

QFN packages excel in thermal management due to the direct connection of the exposed thermal pad to the PCB. This direct thermal path enhances heat dissipation, mitigating the risk of overheating and improving the overall reliability of the electronic component. The efficient thermal characteristics make QFN packages suitable for applications demanding high power or operating in challenging environmental conditions.

Enhanced Electrical Characteristics

QFN packages offer superior electrical performance owing to their shorter electrical paths and reduced inductance compared to traditional leaded packages. The shorter connections contribute to lower resistance and impedance, resulting in improved signal integrity and reduced signal delay. This makes QFN packages advantageous for high-frequency applications and enhances the overall electrical performance of electronic systems.

Cost-Effective Manufacturing

QFN packages contribute to cost-effective manufacturing processes for several reasons. The leadless design simplifies the assembly process, reducing the complexity and time required for component placement on the PCB. Additionally, the absence of external leads streamlines the inspection and testing phases, minimizing the likelihood of defects and improving overall production efficiency. These factors collectively contribute to cost savings in manufacturing, making QFN packages an economical choice for a wide range of electronic applications.

QFN packages offer a compelling set of advantages, including a compact design for space efficiency, improved thermal performance, enhanced electrical characteristics, and cost-effective manufacturing processes. These attributes make QFN packages a preferred choice in various electronic applications, driving their continued adoption in the semiconductor industry.

Other Packaging Types

FAQs About QFN Packages

What are QFN packages?

QFN packages, or Quantum Flat No-leads, are surface-mount integrated circuit packages known for their leadless design. They feature a flat, exposed thermal pad beneath the chip, facilitating improved thermal dissipation and a compact footprint.

What does the QFN stand for?

The acronym QFN stands for “Quantum Flat No-leads,” indicating the absence of traditional external leads in the package design.

What is the difference between DFN and QFN packages?

The main distinction lies in the presence of an exposed thermal pad in QFN packages, enhancing thermal performance. DFN (Dual Flat No-leads) packages may lack this exposed pad.

What are QFN packages?

QFN packages are surface-mount integrated circuit packages recognized for their leadless design, featuring a flat, exposed thermal pad beneath the chip. This design enhances thermal dissipation and enables a compact footprint.

What does the QFN stand for?

The acronym QFN stands for “Quantum Flat No-leads,” emphasizing the absence of conventional external leads in the package configuration.

What is the difference between DFN and QFN packages?

The primary difference lies in the presence of an exposed thermal pad in QFN packages, contributing to improved thermal performance. DFN (Dual Flat No-leads) packages may lack this exposed pad.

What are the advantages of QFN packages?

QFN packages offer advantages such as a compact design for space efficiency, enhanced thermal performance due to the exposed pad, superior electrical characteristics, and cost-effective manufacturing processes.