Understanding the IC Substrate Manufacturing Process

IC substrates are essential components in the semiconductor industry, providing a crucial foundation for integrated circuits (ICs). These substrates serve as the base material on which the microelectronic components of an IC are built. The primary function of IC substrates is to offer mechanical support, ensuring the stability and integrity of the integrated circuit, while also facilitating electrical connections between the various components. In addition to providing structural support, IC substrates play a vital role in heat dissipation, helping to manage the thermal output generated by the IC. As the demand for more advanced, high-performance semiconductor devices grows, the complexity of the IC substrate manufacturing process continues to evolve. With new materials and technologies being introduced, the IC substrate manufacturing process must meet stringent requirements to ensure reliability, performance, and miniaturization of modern ICs. This article will explore the critical steps and challenges involved in the IC substrate manufacturing process.

What is an IC Substrate?

An IC substrate is a critical component in the assembly of integrated circuits (ICs), serving as both the foundation and the medium for electrical connections between the various microelectronic components. Essentially, it is the base material upon which the IC is built, providing mechanical support and thermal management, ensuring that the circuit remains stable and functional. The primary function of an IC substrate is to support the IC’s components while facilitating electrical connections through conductive traces or vias. Additionally, IC substrates play a crucial role in heat dissipation, helping to prevent overheating of the integrated circuit by efficiently transferring heat away from the components.

In the IC substrate manufacturing process, several materials are commonly used to create these substrates, each with its own advantages. Ceramic substrates are known for their excellent thermal conductivity and electrical insulation properties, making them ideal for high-power and high-frequency applications. BT (Bismaleimide-Triazine) substrates are widely used due to their high dielectric strength, low moisture absorption, and reliability in high-performance environments. FR4 substrates, made from fiberglass-reinforced epoxy resin, are commonly used in standard IC packages due to their cost-effectiveness and good electrical performance. Each of these materials undergoes specific processing steps in the IC substrate manufacturing process to meet the exacting standards required for IC production.

Materials Used in IC Substrate

The selection of materials for IC substrates is crucial to the performance, reliability, and manufacturability of integrated circuits. IC substrates must not only provide mechanical support but also facilitate electrical connections and ensure efficient heat dissipation. Several materials are commonly used in the IC substrate manufacturing process, each chosen for its unique properties that meet specific application requirements.

Ceramic Substrates

Ceramic substrates are one of the most commonly used materials for high-performance ICs. They are known for their excellent thermal conductivity, high melting points, and electrical insulation properties. Ceramic substrates, such as alumina (Al2O3) and aluminum nitride (AlN), are ideal for applications requiring efficient heat management, such as power electronics and high-frequency circuits. Their rigidity and resistance to environmental stress make them highly reliable in harsh operating conditions. However, ceramics can be more brittle and expensive to manufacture compared to other materials.

BT (Bismaleimide-Triazine) Resin

BT resin is a popular choice for IC substrates, particularly in applications where reliability and electrical performance are critical. This material offers a balance of excellent electrical properties, low moisture absorption, and high dielectric strength. BT substrates are particularly well-suited for high-frequency, high-performance devices, as they can handle the thermal and electrical demands of modern integrated circuits. BT substrates also exhibit good mechanical strength and are easier to process compared to ceramics, making them a cost-effective option for many IC packages.

Polyimide (PI) Substrates

Polyimide (PI) is a flexible polymer that is often used in IC substrates for flexible or high-density applications. PI substrates offer superior thermal stability, excellent electrical insulation, and chemical resistance. This material is highly suitable for applications where flexibility, high temperature resistance, and durability are important, such as in flexible printed circuits (FPCs) and certain types of high-speed ICs. The use of PI is also beneficial in space-saving designs, as it can be made thinner than ceramic or BT substrates while still providing adequate electrical and thermal performance.

FR4 Substrates

FR4 is a type of fiberglass-reinforced epoxy resin that is widely used in the production of standard IC packages. It offers good mechanical strength, durability, and electrical insulation properties. FR4 substrates are cost-effective and can be easily processed using standard PCB manufacturing techniques, making them a popular choice for mass-market ICs. However, FR4 may not provide the same level of thermal conductivity or high-frequency performance as ceramic or BT substrates, making it more suitable for lower-performance or lower-cost applications.

Factors Influencing Material Selection in the IC Substrate Manufacturing Process

Several key factors influence the selection of materials for IC substrates. These include:

- Conductivity: The material’s ability to conduct electrical signals is critical, especially for high-speed ICs. Materials like BT resin and ceramics are selected for their low electrical resistance, ensuring efficient signal transmission and minimal power loss.

- Thermal Conductivity: Efficient heat dissipation is essential in modern ICs, especially in power and high-frequency applications. Materials such as ceramics, particularly aluminum nitride (AlN), are chosen for their superior thermal conductivity, which helps in managing the heat generated by the IC components.

- Mechanical Strength: The substrate must be mechanically strong to support the delicate components of the IC and withstand the stresses during manufacturing and operation. Ceramic materials and BT resins provide excellent mechanical strength, while flexible materials like Polyimide are chosen for their flexibility without compromising the integrity of the circuit.

- Cost and Manufacturability: While materials like ceramics and Polyimide offer superior performance, they can be more expensive to process compared to FR4. The IC substrate manufacturing process needs to balance performance requirements with cost constraints, especially for consumer electronics and mass-produced ICs.

- Environmental Resistance: IC substrates need to withstand environmental factors such as moisture, temperature fluctuations, and mechanical stress. Materials like BT resin and Polyimide are chosen for their resistance to moisture absorption and their ability to perform under extreme environmental conditions.

Each of these factors is carefully considered during the IC substrate manufacturing process to ensure that the final product meets the performance, durability, and cost requirements of the specific IC application. By selecting the appropriate material, manufacturers can optimize the overall performance of the integrated circuit and meet the demands of modern electronic devices.

The IC Substrate Manufacturing Process

The IC substrate manufacturing process involves several complex and precise steps that ensure the final product can support the integrated circuits and perform optimally under various electrical and mechanical conditions. Below is a detailed breakdown of the key steps involved in the manufacturing of IC substrates.

Material Preparation

The first step in the IC substrate manufacturing process is selecting and preparing the appropriate materials. The materials used for IC substrates, such as ceramic, BT resin, polyimide, or FR4, are chosen based on the specific requirements of the IC, such as electrical performance, thermal conductivity, and mechanical strength.

After the material is selected, it undergoes preprocessing, which may include cutting the raw material into the required sizes, polishing the surface to achieve smoothness, and conditioning the material to ensure consistency. For example, ceramic substrates may require sintering to enhance their mechanical and thermal properties, while FR4 might be laminated with fiberglass layers to improve strength.

Patterning and Etching

Patterning and etching are crucial steps in the IC substrate manufacturing process where microscopic electrical circuits are created on the substrate. The patterning process typically begins with the application of a photoresist layer on the surface of the substrate. This photoresist is then exposed to ultraviolet (UV) light through a photomask that defines the circuit design.

After exposure, the photoresist is developed, leaving behind a pattern that corresponds to the circuit layout. The exposed areas of the substrate are then etched using chemical etchants to remove the material and form the desired conductive pathways. This step is essential for creating the intricate traces and vias that will connect the different parts of the IC. The etching process must be highly controlled to ensure the precise formation of patterns that meet the required electrical specifications.

Lamination and Molding

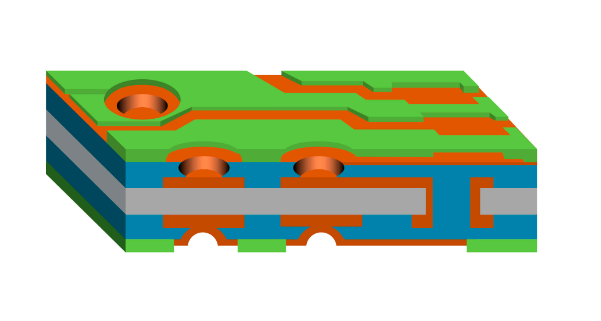

Lamination and molding are the next key steps in the IC substrate manufacturing process. In this stage, multiple layers of material are stacked and bonded together to form the final IC substrate. For example, in the case of BT resin substrates, layers of resin are applied and laminated under high pressure and temperature to form a solid, durable structure.

In addition to bonding layers of resin or fiberglass, molding is often used to encapsulate sensitive components within the substrate. The molding process helps protect the substrate from mechanical stress and environmental factors, and it also assists in shaping the substrate into the desired form. For ceramic substrates, a similar process is used to sinter the material and bond layers together to achieve the necessary thickness and strength.

Drilling and Lead Frame Installation

Once the substrate has been laminated and molded, the next step is drilling. Precise holes are drilled into the substrate to create vias and other openings that will be used for electrical connections. These vias enable the routing of electrical signals between different layers of the substrate or between the IC and external components. The drilling process must be highly accurate, as even slight misalignments can cause electrical failure or impair performance.

After drilling, the lead frame is installed. The lead frame is a metallic structure that will be used to connect the IC substrate to external devices such as connectors, power supplies, or other ICs. The lead frame is typically bonded or soldered into place, ensuring secure electrical contact between the IC and the surrounding system.

Surface Treatment and Protection

The surface of the IC substrate must undergo various treatments to enhance its performance and durability. One of the primary surface treatments is oxidation resistance, which helps protect the substrate from the corrosive effects of environmental factors such as moisture and temperature fluctuations.

Surface treatments such as electroplating, gold or copper plating, or applying protective coatings are used to improve corrosion resistance, electrical conductivity, and bonding strength. These treatments help ensure that the IC substrate can function reliably over a long period of time, even in demanding applications such as power electronics, high-frequency circuits, or automotive systems.

Quality Inspection and Testing

Once the IC substrate is fully manufactured, it undergoes rigorous quality inspection and testing to ensure it meets the required electrical, mechanical, and environmental standards. Electrical testing involves verifying the integrity of the conductive traces, vias, and overall signal pathways. Any short circuits, broken connections, or insufficient electrical performance are identified and corrected.

Mechanical testing assesses the physical properties of the substrate, including its strength, flexibility, and durability under stress. Environmental testing checks the substrate’s performance under extreme temperature variations, humidity, and other challenging conditions to ensure it can withstand real-world usage.

In addition to electrical and mechanical testing, visual inspections and automated optical inspections (AOI) are often performed to detect any surface defects or inconsistencies. These inspections help catch manufacturing defects before the substrate is used in the assembly of the final IC product.

By the end of this step, only substrates that meet all the specifications and quality standards are approved for use in IC packaging, ensuring the high performance and reliability of the integrated circuits they support.

The IC substrate manufacturing process is a highly intricate and precise procedure that involves careful material selection, patterning, etching, and various mechanical treatments to create substrates capable of supporting advanced integrated circuits. Each step in the process must be carried out with precision to ensure the final product meets the stringent performance and reliability requirements for modern electronic devices. From material preparation to quality testing, every stage of the manufacturing process plays a vital role in producing high-quality IC substrates.

Challenges in IC Substrate Manufacturing

The IC substrate manufacturing process is a complex and highly specialized procedure, and as demand for advanced integrated circuits grows, manufacturers face numerous challenges in achieving the desired performance and reliability. Below are some of the key technical challenges encountered during the manufacturing process, as well as how technological innovations are addressing these issues.

Size Precision and Miniaturization

As integrated circuits continue to shrink in size while increasing in complexity, maintaining precise size and dimensional accuracy in the substrates becomes a significant challenge. Modern ICs, especially those used in high-performance computing, telecommunications, and consumer electronics, require substrates that can support increasingly smaller and more densely packed components.

The IC substrate manufacturing process must produce substrates with extremely tight tolerances to ensure proper alignment and functionality of the IC components. Even slight deviations in size or placement can lead to electrical failures or reduced performance. The challenge lies in manufacturing substrates that maintain this high degree of precision while also supporting complex multilayer designs and smaller feature sizes.

Technological Innovations: To address these challenges, advancements in photolithography, laser drilling, and precision CNC machining have significantly improved the accuracy of patterning and drilling in substrates. These technologies enable the creation of smaller vias and finer circuit traces, meeting the miniaturization demands of modern ICs. Additionally, new developments in automated inspection systems and AI-based quality control have helped detect even the smallest defects, ensuring tighter tolerances are maintained throughout production.

Thermal Management

Heat dissipation is a critical issue in IC substrate manufacturing, especially as the power consumption and density of integrated circuits increase. ICs generate heat during operation, and improper thermal management can lead to overheating, reduced performance, and even failure of the circuit. Efficient heat transfer from the IC to the substrate and the environment is crucial for maintaining the long-term reliability and efficiency of electronic devices.

In the IC substrate manufacturing process, the selection of materials with suitable thermal conductivity is essential. However, as the power density of ICs rises, traditional substrate materials may not provide adequate thermal management. This challenge is further compounded by the need to balance thermal conductivity with other performance factors, such as electrical properties and mechanical strength.

Technological Innovations: Innovations in substrate materials, such as the development of high-performance ceramics (e.g., aluminum nitride), and the incorporation of thermal vias and heat spreaders have greatly improved thermal management. The use of advanced composite materials and the integration of microchannel cooling systems directly into the substrate structure is also being explored to enhance heat dissipation. Furthermore, the trend toward advanced 3D packaging and the use of stacked ICs allow for better thermal distribution by optimizing the layout of components and their proximity to heat sinks.

Material Compatibility

Another significant challenge in the IC substrate manufacturing process is ensuring compatibility between the substrate material and the various layers, components, and interconnections that make up the final IC package. For example, the material used for the substrate must bond effectively with metals, conductive traces, solder balls, and other materials used in IC assembly. Additionally, substrates must be compatible with the specific manufacturing processes, such as soldering, wire bonding, and molding, without introducing defects.

In some cases, the materials used in the substrate may not possess ideal characteristics for all stages of manufacturing, leading to issues such as poor adhesion, delamination, or mechanical failure. Achieving optimal material compatibility is crucial to ensuring that the final IC package performs reliably across its entire operational life.

Technological Innovations: To improve material compatibility, manufacturers are increasingly using advanced surface treatments and bonding techniques, such as electroplating and adhesive bonding, which enhance the adhesion between the substrate and the interconnecting materials. In addition, the development of new polymer resins and composite materials with better chemical resistance and flexibility has helped improve compatibility. Advances in molecular-level bonding and the use of nanotechnology are also paving the way for better adhesion and performance, particularly in multi-material substrates.

Moisture and Contamination Control

Moisture absorption and contamination are significant concerns in the IC substrate manufacturing process. Even small amounts of moisture trapped within the substrate or contamination from foreign particles can compromise the integrity and performance of the IC. These issues can lead to electrical shorts, corrosion of conductive traces, or failure of the substrate under thermal cycling conditions.

Substrate materials, especially organic-based materials like FR4 and BT resin, are particularly susceptible to moisture absorption, which can alter their electrical properties or lead to mechanical issues during the IC packaging process. Contamination from dust, oils, or particulate matter can also cause defects during the manufacturing process, affecting the final quality of the IC substrate.

Technological Innovations: To mitigate these issues, manufacturers have developed better encapsulation techniques and moisture-resistant materials. The application of protective coatings such as conformal coatings or thin-film barriers helps reduce moisture absorption and protect against contamination. Advanced cleanroom technologies and improved air filtration systems are also crucial in reducing contamination during the manufacturing process. Furthermore, the development of hermetic sealing and more robust materials that prevent moisture infiltration has significantly improved the durability and reliability of IC substrates.

Cost and Scalability

While achieving high precision, superior thermal management, and material compatibility is essential, it is equally important to maintain cost-effectiveness and scalability in the IC substrate manufacturing process. As demand for ICs increases, especially for consumer electronics and automotive applications, manufacturers must find ways to produce high-quality substrates at scale without compromising on performance. Cost pressures often lead to trade-offs between material quality, manufacturing techniques, and production volume.

Technological Innovations: Automation and advances in manufacturing techniques, such as roll-to-roll processing for flexible substrates or high-throughput photolithography for fine patterning, have helped reduce production costs. Additionally, the use of AI and machine learning for process optimization and predictive maintenance is increasing efficiency and reducing waste. New materials with better performance and lower cost are also being developed, enabling manufacturers to meet both performance standards and cost constraints.

The IC substrate manufacturing process faces several technical challenges, including maintaining size precision, managing thermal dissipation, ensuring material compatibility, controlling moisture and contamination, and balancing cost with scalability. However, ongoing technological innovations in materials science, automation, and process optimization are providing effective solutions to these challenges. As the demand for more advanced, reliable, and high-performance ICs continues to grow, these innovations will play a crucial role in shaping the future of IC substrate manufacturing, driving the development of smaller, faster, and more efficient electronic devices.

Applications of IC Substrates

IC substrates are fundamental components in the electronics industry, supporting the assembly of integrated circuits (ICs) and enabling their functionality in a wide range of applications. The IC substrate manufacturing process results in highly specialized substrates that are crucial in various industries, including communications, automotive electronics, and consumer electronics. These substrates not only provide mechanical support but also ensure electrical interconnection, thermal management, and long-term reliability, which are vital for the performance of the ICs they house.

Communications Industry

IC substrates play a pivotal role in the communications industry, particularly in high-frequency and high-speed signal transmission. As communication systems evolve to support faster data rates and more complex technologies (such as 5G, Wi-Fi 6, and fiber optics), the performance requirements for IC substrates have become more demanding.

In communication systems, IC substrates are used in components like baseband processors, power amplifiers, and RF (radio frequency) modules. These ICs require substrates that can handle high-frequency signals while maintaining signal integrity. Materials such as BT resin and ceramic substrates are often used in these applications because of their excellent electrical insulation properties and ability to handle high-frequency signals without significant loss or distortion.

For 5G and other advanced wireless communication technologies, IC substrates also need to provide effective thermal management. High-performance substrates with superior thermal conductivity, such as aluminum nitride ceramics, are often used to ensure that the components remain within acceptable temperature ranges during operation. This allows communication systems to operate efficiently and reliably, even under the demanding conditions of high-speed transmission.

Automotive Electronics

The automotive industry relies increasingly on advanced IC substrates to support the growing number of electronic systems in modern vehicles. From safety systems like airbags and ABS to infotainment, navigation, and autonomous driving technologies, automotive applications demand highly reliable IC substrates that can withstand harsh environments, including high temperatures, vibrations, and exposure to chemicals.

IC substrates used in automotive electronics must be able to operate under extreme conditions and maintain performance over the long term. For instance, powertrain systems, electric vehicles (EVs), and advanced driver-assistance systems (ADAS) require substrates that can manage high-power, high-voltage, and high-frequency signals. Ceramic and high-performance BT substrates are commonly used in automotive power electronics due to their durability and thermal stability.

Automotive IC substrates are designed to handle electromagnetic interference (EMI) and provide shielding to prevent signal distortion. With the rapid adoption of electric and autonomous vehicles, the demand for high-performance IC substrates capable of supporting complex sensors, power converters, and communication systems continues to grow.

Consumer Electronics

IC substrates are also integral to the consumer electronics industry, which includes products such as smartphones, laptops, tablets, wearables, and home appliances. These devices often require compact, lightweight, and high-performance ICs to meet the expectations of consumers for faster processing, longer battery life, and higher functionality.

In consumer electronics, IC substrates are used in a wide range of components, including processors, memory chips, power management ICs, and display drivers. As these devices become more compact and feature-rich, the IC substrates must be able to support the increasing number of transistors and ensure efficient heat dissipation, while still maintaining a small form factor. FR4 substrates are commonly used for general-purpose consumer electronics due to their balance of performance and cost-effectiveness. However, for high-performance devices such as smartphones and gaming consoles, more advanced substrates, including BT resin and ceramic, are often used to ensure high-speed processing and thermal efficiency.

The increasing demand for flexible electronics in consumer devices is also driving innovation in IC substrates. Flexible polymer substrates, such as polyimide (PI), are being utilized in applications like flexible displays, wearable electronics, and foldable smartphones. These substrates allow for more versatile designs and contribute to the lightweight and portable nature of modern consumer products.

Significance of IC Substrates in High-Frequency, High-Speed Transmission IC Designs

One of the most critical applications of IC substrates is in high-frequency, high-speed transmission IC designs. These ICs are used in technologies that require rapid data processing and communication, such as 5G networks, satellite communication, radar systems, and high-speed computing.

In these applications, the IC substrate must provide precise signal routing and minimize signal loss or interference. The substrate must also support high-speed switching of electronic signals without introducing delays, which is essential for maintaining the performance of high-speed circuits.

For example, in 5G and high-frequency RF IC designs, substrates made of materials like ceramic or advanced composites are commonly used due to their superior electrical properties. These materials help minimize signal degradation over distance and ensure that signals can travel at higher speeds with minimal loss. Ceramic substrates, with their high dielectric constant and low signal loss characteristics, are often chosen for high-frequency applications because they allow for faster signal transmission and better impedance matching, which is crucial for maintaining signal integrity.

The IC substrate must be able to manage the heat generated by high-speed signal transmission. The higher the frequency, the more power is required to maintain signal strength, which results in increased heat. Substrates with good thermal conductivity, such as aluminum nitride (AlN) and other high-performance materials, help dissipate this heat efficiently, preventing overheating and ensuring the long-term reliability of the IC.

In high-speed data transmission systems, such as those used in optical networks, the substrate must also ensure that the IC can interface effectively with other components, such as fiber optics and laser diodes. The ability to handle both high-speed data transmission and power management is a key factor in the selection of IC substrates for these applications.

Other Specialized Applications

In addition to the industries mentioned above, IC substrates are also used in a variety of specialized applications, such as medical devices, military electronics, and industrial automation. In medical electronics, IC substrates are used in devices like pacemakers, diagnostic equipment, and medical imaging systems, where reliability and miniaturization are crucial. Similarly, in military and aerospace applications, IC substrates must withstand extreme conditions, such as high radiation and temperature fluctuations, while maintaining high performance.

IC substrates are integral to a wide range of industries, from communications and automotive to consumer electronics and specialized applications. Their importance in high-frequency, high-speed transmission designs is especially significant as technology advances and the demand for faster, more reliable systems increases. The IC substrate manufacturing process continues to evolve to meet the performance, thermal management, and miniaturization requirements of modern electronic devices, ensuring that IC substrates remain central to the development of next-generation technologies across many sectors.

Global IC Substrate Manufacturers

The global IC substrate manufacturing process is dominated by a handful of major manufacturers who lead the market in terms of technological advancements, production capacity, and market share. These companies are pivotal in meeting the increasing demand for high-performance IC substrates across various industries, including telecommunications, automotive electronics, consumer devices, and more. Below, we explore some of the key players in the IC substrate manufacturing market, their technological strengths, and the trends that are shaping their market position.

Taiwan Semiconductor Manufacturing Company (TSMC)

As one of the largest and most influential companies in the semiconductor industry, TSMC is a leader in both semiconductor fabrication and the production of IC substrates. TSMC primarily focuses on high-end IC substrates for advanced applications in consumer electronics, telecommunications, and automotive industries.

Technological Strengths: TSMC is well-known for its ability to integrate advanced packaging and substrate technologies into its production processes. It has developed advanced solutions like System-in-Package (SiP) and 3D packaging, which combine multiple ICs into a single package for improved performance and reduced footprint. This ability to integrate various packaging and substrate technologies positions TSMC as a key player in the high-frequency, high-speed transmission IC market, especially for applications in 5G and AI-driven electronics.

Market Trends: As 5G, automotive electronics, and IoT continue to grow, TSMC is investing heavily in expanding its production capacity for advanced IC substrates. The company is also increasing its focus on developing substrate materials with better thermal management properties, as the demand for heat-resistant substrates in high-power applications grows.

ASE Group (Advanced Semiconductor Engineering, Inc.)

ASE Group is one of the leading global suppliers of semiconductor packaging and IC substrates, offering a wide range of solutions, from traditional printed circuit board (PCB) substrates to advanced multi-layer substrates used in high-performance ICs.

Technological Strengths: ASE Group specializes in advanced packaging solutions such as flip-chip bonding, wafer-level packaging, and 3D IC packaging. It also provides high-density interconnect (HDI) substrates, which are crucial for miniaturizing IC designs while maintaining high performance. ASE’s ability to manufacture high-quality IC substrates with fine-pitch interconnections makes it a key player in the mobile and consumer electronics markets, where miniaturization and high performance are critical.

Market Trends: ASE is capitalizing on the growing demand for high-speed and high-frequency IC substrates required for 5G applications. Additionally, the company is expanding its production capabilities for automotive IC substrates as the shift toward electric vehicles (EVs) and autonomous driving systems accelerates. ASE is also investing in R&D to develop more cost-effective substrate solutions, in line with market demand for affordability without compromising quality.

Samsung Electro-Mechanics

Samsung Electro-Mechanics, a subsidiary of Samsung Electronics, is a major global player in the manufacturing of IC substrates. The company is particularly strong in the mobile and consumer electronics sectors, supplying substrates for high-performance smartphones, wearables, and other portable devices.

Technological Strengths: Samsung Electro-Mechanics has invested significantly in the development of high-performance substrates, particularly those for mobile communication devices and advanced consumer electronics. Its expertise in organic substrates such as BT resin and advanced multilayered PCBs allows it to produce high-density and highly reliable IC substrates. Additionally, the company has made advancements in substrates for camera modules, which are integral to modern smartphones and smart devices.

Market Trends: Samsung Electro-Mechanics is focusing on improving the thermal conductivity and electrical performance of its substrates to meet the demands of 5G and high-performance computing. The company is also a key player in the automotive market, providing IC substrates for applications in electric vehicles (EVs) and driver assistance systems. Samsung’s continuous investment in R&D aims to expand its capabilities in flexible and high-performance IC substrates, which are essential for the future of flexible displays and wearable electronics.

Shinko Electric Industries Co., Ltd.

Shinko Electric is a Japanese company that has long been a leader in the IC substrate market, known for its expertise in the production of high-performance substrates for power electronics, automotive applications, and telecommunications.

Technological Strengths: Shinko Electric specializes in advanced substrates for high-power applications, such as those used in power modules, automotive systems, and industrial equipment. The company is recognized for its ability to produce substrates with excellent thermal conductivity and reliability. Shinko also manufactures substrates for RF ICs, a crucial component in wireless communication systems like 5G.

Market Trends: Shinko is capitalizing on the growing demand for automotive IC substrates, especially in electric vehicles (EVs), where high-performance power electronics are required. The company is also expanding its portfolio of substrates designed for 5G base stations, which require substrates that can handle high-frequency signals and power dissipation. As the demand for smart automotive systems and IoT devices grows, Shinko is increasing its investment in next-generation substrate technologies to maintain its leadership position.

Kyocera Corporation

Kyocera is a leading manufacturer of electronic components, including IC substrates. The company is particularly focused on providing high-quality ceramic substrates, which are essential in various high-performance applications, including power devices, automotive electronics, and industrial machinery.

Technological Strengths: Kyocera is recognized for its ceramic-based IC substrates, which are used extensively in power electronics for automotive and industrial applications. These substrates are known for their superior thermal conductivity and ability to withstand extreme operating conditions. Kyocera also produces advanced ceramic substrates for high-frequency RF ICs used in wireless communication devices and mobile applications.

Market Trends: As automotive systems become more electrified and autonomous, Kyocera is expanding its production capabilities for automotive IC substrates, focusing on high-performance, high-reliability substrates capable of withstanding harsh environments. Additionally, the company is investing in technologies to enhance the thermal management capabilities of its substrates, which are crucial for the continued miniaturization of electronic systems.

Unimicron Technology Corporation

Unimicron is a Taiwanese company that is one of the largest PCB manufacturers globally, and it also produces a variety of IC substrates. Unimicron is particularly strong in providing substrates for consumer electronics, including smartphones, computers, and TVs.

Technological Strengths: Unimicron’s strength lies in its ability to manufacture both traditional and advanced IC substrates, including those used in high-performance consumer electronics. The company is particularly known for its high-density interconnect (HDI) substrates, which allow for smaller form factors and higher interconnect densities, a key requirement in modern mobile devices.

Market Trends: Unimicron is focusing on expanding its production of IC substrates for the growing 5G market. The company is also investing in the development of more cost-effective yet high-performance substrates for consumer electronics, as demand for portable, high-functioning devices continues to rise. Unimicron’s ability to balance cost with technological innovation has made it a key player in the competitive consumer electronics market.

The global IC substrate manufacturing process is shaped by a number of key players, each bringing unique technological strengths to the table. Companies like TSMC, ASE Group, Samsung Electro-Mechanics, Shinko Electric, Kyocera, and Unimicron are not only meeting the demand for high-performance IC substrates in communication, automotive, and consumer electronics, but they are also driving innovations that will shape the future of electronic devices. As market trends continue to evolve, with increasing emphasis on 5G, IoT, automotive electronics, and high-frequency communication, these manufacturers are positioned to maintain their dominance by focusing on advanced materials, thermal management, and miniaturization technologies.

Future Trends in IC Substrate Manufacturing

The IC substrate manufacturing process is evolving rapidly to meet the increasing demands of emerging technologies, including high-performance computing, 5G, autonomous vehicles, and advanced consumer electronics. As the need for smaller, faster, and more reliable electronic systems grows, the substrate industry is witnessing several key trends and innovations that are expected to shape its future. Below are some of the most significant emerging trends and potential improvements in IC substrate materials and manufacturing processes.

3D Packaging and Advanced Substrate Technologies

One of the most exciting developments in the field of IC substrates is the shift toward 3D packaging, which involves stacking multiple integrated circuits on top of one another in a vertical arrangement. This allows for much higher densities of functionality within a smaller footprint, which is crucial for mobile devices, high-performance computing, and IoT applications.

In 3D packaging, substrates play a key role in providing electrical connections between the stacked ICs. This approach significantly reduces the size and improves the performance of electronic devices while maintaining or even improving heat dissipation. Technologies like Through-Silicon Vias (TSVs) and Microbumps are being used to create high-density interconnections between the ICs, enabling faster data transfer rates and reducing signal interference.

The IC substrate manufacturing process for 3D packaging is more complex than traditional 2D packaging and involves precision alignment, stacking, and bonding of layers. This requires advanced materials and manufacturing techniques, such as ultra-fine-pitch interconnections, advanced bonding methods, and the use of advanced composite materials to improve mechanical strength and thermal conductivity.

As 3D packaging continues to gain traction, the development of substrates that can efficiently handle multiple stacked ICs will be crucial. This trend is particularly important in applications like high-performance servers, AI processing units, and advanced mobile devices, where space constraints and power efficiency are critical.

Advancements in Microelectronics and Miniaturization

The relentless push toward smaller, faster, and more powerful devices is driving significant advancements in microelectronics. As semiconductor nodes continue to shrink, there is an increasing need for IC substrates that can accommodate higher densities of interconnects and ensure reliable performance at very small scales.

Nanoelectronics, which involves manipulating individual atoms and molecules to create circuits at the nanoscale, is expected to lead to the development of even smaller ICs. Substrate materials will need to evolve to support these advancements, with new materials being explored to ensure better conductivity, heat dissipation, and mechanical strength at smaller sizes.

Flexible electronics is another area where microelectronics is influencing IC substrate manufacturing. The growing demand for wearable devices, flexible displays, and foldable electronics requires substrates that can not only handle the demands of microelectronics but also be lightweight, durable, and bendable without losing performance. Flexible IC substrates made from materials like polyimide (PI) and organic polymers are gaining popularity in this field.

Improvements in IC Substrate Materials

The selection of materials used in IC substrates is crucial for performance, reliability, and cost-effectiveness. As the need for higher performance in both consumer and industrial applications grows, several potential improvements are being explored in substrate materials:

- High-Performance Ceramics: Ceramic substrates, particularly those made from materials like aluminum nitride (AlN) and sapphire, offer excellent thermal conductivity, making them ideal for high-power applications. As power densities increase, the demand for ceramic substrates with better thermal management properties will grow. Future advancements in ceramic materials could result in more cost-effective and thermally efficient substrates for power electronics, automotive systems, and 5G networks.

- Advanced Composite Materials: The use of composite materials, such as silicon carbide (SiC) and diamond-like carbon (DLC) coatings, is expected to improve the electrical and thermal performance of IC substrates. These materials can handle higher temperatures and provide superior conductivity, which is essential for applications like electric vehicles and high-power industrial electronics.

- Organic Substrates with Enhanced Properties: While materials like FR4 and BT resin have been the staple in many IC substrate applications due to their cost-effectiveness, future innovations are likely to involve the development of organic substrates with superior mechanical properties and thermal resistance. These enhanced organic materials may be more suited for high-speed communication devices, consumer electronics, and automotive applications.

- Graphene and Carbon Nanotubes: Graphene, a one-atom-thick layer of carbon, is known for its exceptional electrical conductivity and heat dissipation properties. Researchers are exploring the use of graphene in IC substrates to provide faster signal transmission and better thermal management. Carbon nanotubes (CNTs), which have similar properties, are also being studied for their potential to replace traditional copper interconnects in IC substrates.

Sustainability and Eco-Friendly Materials

As environmental concerns grow, the semiconductor industry is facing increasing pressure to adopt more sustainable practices in IC substrate manufacturing. This includes reducing the environmental impact of raw material extraction, energy consumption during production, and waste management.

The development of eco-friendly substrates is a key focus, with materials that are both high-performing and sustainable being actively researched. Substituting hazardous chemicals used in traditional substrate production, such as lead, with more environmentally friendly alternatives is another critical area of innovation. Additionally, manufacturers are looking for ways to recycle and repurpose substrate materials to reduce waste in the long run.

The move toward bio-based materials is also gaining traction. Researchers are exploring organic, biodegradable substrates derived from renewable sources such as plant-based polymers, which could reduce the overall environmental footprint of electronic devices.

Advanced Manufacturing Techniques and Automation

The IC substrate manufacturing process itself is also undergoing transformations, with a strong focus on automation, precision, and cost efficiency. Innovations in 3D printing and additive manufacturing are expected to have a significant impact on the way IC substrates are produced. These technologies allow for the creation of complex, customized substrates without the need for expensive molds or tooling, making the process more flexible and cost-effective.

Advanced etching and patterning techniques, such as nano-imprint lithography and electron beam lithography, are also expected to play a key role in the miniaturization of IC substrates. These techniques can enable finer details and higher-density interconnections, which are essential for future microelectronics and advanced packaging solutions like 3D ICs.

AI and machine learning are being integrated into the manufacturing process to optimize yield, reduce defects, and enhance the overall quality control of IC substrates. Predictive maintenance, automated inspections, and process control systems are becoming increasingly important in ensuring that substrates meet stringent performance and reliability standards.

Integration of AI and IoT in Substrate Design

The rise of AI and the Internet of Things (IoT) is influencing the future of IC substrate design and manufacturing. As devices become smarter and more interconnected, the substrates will need to support advanced processing capabilities and connectivity while maintaining low power consumption.

Future IC substrates will likely integrate more advanced components, such as sensors, antennas, and memory chips, to meet the needs of the growing IoT ecosystem. The development of multi-functional substrates, which combine various types of ICs into a single package, is a key area of interest. These substrates could support a range of applications, from smart cities to autonomous systems, and are expected to reduce the overall size and complexity of devices.

The future of the IC substrate manufacturing process is marked by continuous innovation across materials, manufacturing techniques, and application areas. With advancements in 3D packaging, microelectronics, and materials like graphene and ceramics, the industry is poised to meet the ever-growing demands of high-speed, high-frequency, and power-efficient devices. Sustainability, eco-friendly materials, and AI-driven manufacturing are also expected to play a central role in shaping the next generation of IC substrates. As these trends evolve, the IC substrate industry will be critical in enabling the future of electronics across all sectors, from consumer devices to advanced automotive and communication systems.

FQAs Abut IC Substrate Manufacturing Process

What are the processes of IC substrate?

The processes involved in IC substrate manufacturing typically include material preparation, patterning and etching, lamination and molding, drilling and lead frame installation, surface treatment and protection, and quality inspection and testing. Each of these steps ensures the proper fabrication of substrates that provide mechanical support and electrical connections for integrated circuits (ICs).

What is the process of semiconductor substrate manufacturing?

Semiconductor substrate manufacturing includes several steps, such as:

Material Selection and Preparation: Choosing the right material, like silicon, ceramic, or composite, and preparing it for processing.

Wafer Fabrication: The wafer is sliced, polished, and cleaned.

Photolithography and Etching: Patterns are etched onto the substrate to create circuits and interconnections.

Deposition: Thin layers of materials are deposited onto the substrate for electrical insulation or conduction.

Doping: Adding impurities to modify electrical properties.

Packaging: After testing, the wafer is diced, and ICs are packaged for use in electronic devices.

The manufacturing process is highly precise and involves multiple stages of patterning and material handling to ensure the final substrate meets the required electrical, thermal, and mechanical properties.

What is IC manufacturing process?

The IC manufacturing process includes the following main stages:

Design and Masking: The integrated circuit is designed, and photomasks are created for pattern transfer.

Wafer Preparation: Semiconductor wafers are prepared by cleaning and polishing.

Photolithography: Patterns are transferred onto the wafer using ultraviolet light.

Etching and Deposition: The wafer undergoes etching to remove unwanted material and deposition to apply new materials.

Doping: The wafer is exposed to dopants to change its conductivity.

Metallization: Metal layers are applied to create electrical connections between components.

Testing and Packaging: After testing the functionality of the IC, it is packaged for integration into devices.

What is usually the substrate of IC made up of?

The substrate of an IC is typically made of materials such as:

Silicon: The most common material used for semiconductor ICs, known for its electrical properties and ease of fabrication.

Ceramics: Often used for high-power or high-temperature applications due to their excellent thermal properties.

BT Resin (Bismaleimide-Triazine): A common organic material used for IC substrates, offering good mechanical strength and thermal conductivity.

Polyimide (PI): Used in flexible electronics and for its heat resistance and high electrical insulation properties.

FR4: A fiberglass-reinforced resin, used in low-cost applications, particularly for printed circuit boards (PCBs) but also found in some IC substrates.