Leading the Future: Multilayer Flip Chip Innovations

Flip Chip technology has revolutionized the semiconductor industry, offering enhanced performance and reliability in electronic packaging. Its development has been propelled by the need for miniaturization, increased functionality, and higher interconnection densities in electronic devices. In this context, Multilayer Flip Chip Substrate emerges as a critical component, providing a robust foundation for advanced packaging solutions. Its significance lies in enabling high-density interconnects, minimizing signal delay, and enhancing thermal management, crucial for modern electronics. By facilitating the seamless integration of semiconductor devices onto substrates, Multilayer Flip Chip Substrate elevates the efficiency and performance of various applications, ranging from telecommunications and automotive electronics to industrial automation. Understanding its role is pivotal for grasping the transformative potential of contemporary electronic packaging solutions.

Overview of Flip Chip Technology

What is Flip Chip Technology

Flip Chip technology, also known as controlled collapse chip connection (C4), is a method used in semiconductor device assembly and packaging. Unlike traditional wire bonding, where the bond wires are connected from the die to the package substrate, Flip Chip technology directly connects the semiconductor die to the substrate or printed circuit board (PCB) through metal bumps or solder balls. This direct connection enables shorter interconnect lengths, higher interconnection densities, and improved electrical performance.

Comparison between Flip Chip and Traditional BGA Technology

In traditional Ball Grid Array (BGA) technology, the semiconductor die is mounted face-up on the package substrate, and the electrical connections are made through an array of solder balls on the bottom surface of the package. In contrast, Flip Chip technology involves mounting the semiconductor die face-down, allowing for more efficient heat dissipation and shorter electrical paths. This configuration results in superior electrical and thermal performance compared to traditional BGA technology.

Advantages and Application Areas of Flip Chip Technology

Flip Chip technology offers several advantages over traditional packaging methods:

1. Improved Electrical Performance: Shorter interconnect lengths and reduced parasitic capacitance and inductance lead to faster signal transmission and higher bandwidth.

2. Enhanced Thermal Management: Direct die attachment facilitates efficient heat dissipation, enabling better thermal performance and reliability.

3. Higher Interconnection Density: Flip Chip technology allows for a greater number of connections in a smaller footprint, enabling the integration of more complex circuits in compact devices.

4. Increased Reliability: The absence of bond wires reduces the risk of wire bond failures, improving the overall reliability of the packaged device.

These advantages make Flip Chip technology well-suited for a wide range of applications, including high-performance computing, telecommunications, automotive electronics, consumer electronics, and industrial automation. Its ability to deliver superior electrical performance, thermal management, and reliability has positioned Flip Chip technology as a preferred packaging solution for advanced semiconductor devices.

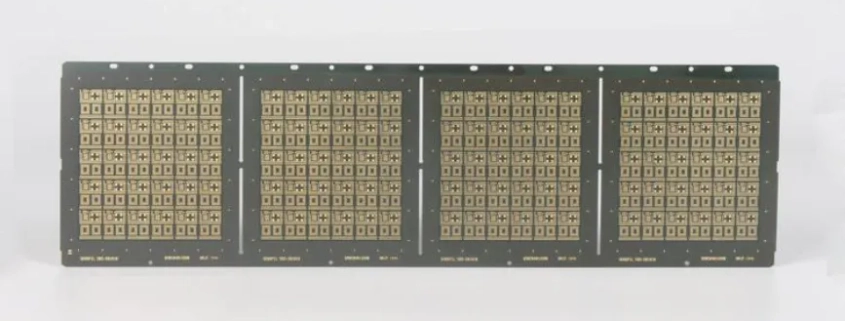

Structure and Characteristics of Multilayer Flip Chip Substrate

Structure Composition

Multilayer Flip Chip Substrate consists of several layers of materials that serve specific functions in electronic packaging:

1. Base Layer: Typically made of a dielectric material such as FR-4 or polyimide, the base layer provides mechanical support and insulation for the substrate.

2. Build-Up Layers: These layers, often composed of high-density interconnect (HDI) materials like thin films of copper, are stacked on top of the base layer. Build-up layers facilitate the routing of electrical connections between the Flip Chip die and other components on the substrate.

3. Conductive Traces: Copper traces are patterned on the build-up layers to establish electrical connections between the Flip Chip die, passive components, and external circuitry.

4. Solder Mask and Surface Finish: These layers protect the conductive traces and provide a surface for soldering components onto the substrate.

Characteristics

Multilayer Flip Chip Substrate offers several key advantages:

1. High Density: By utilizing multiple build-up layers, Multilayer Flip Chip Substrate achieves a high interconnect density, allowing for the integration of numerous components in a compact space.

2. High Reliability: The direct connection between the Flip Chip die and substrate, along with the use of reliable materials and manufacturing processes, enhances the overall reliability of the electronic package.

3. Low Signal Delay: The shorter interconnect lengths and reduced parasitic capacitance and inductance in Multilayer Flip Chip Substrate lead to minimal signal delay and improved signal integrity.

4. Excellent Thermal Management: The substrate’s design facilitates efficient heat dissipation, ensuring optimal thermal performance and reliability of the packaged device.

Comparison with Traditional BGA Substrate

Compared to traditional Ball Grid Array (BGA) substrates, Multilayer Flip Chip Substrate offers several advantages:

1. Higher Interconnect Density: Multilayer Flip Chip Substrate supports a greater number of connections in a smaller footprint, enabling the integration of more complex circuits.

2. Improved Electrical Performance: Shorter interconnect lengths and reduced parasitic effects result in superior electrical performance compared to BGA substrates.

3. Enhanced Thermal Management: The direct die attachment and optimized substrate design of Multilayer Flip Chip Substrate provide better thermal conductivity and heat dissipation capabilities than BGA substrates.

4. Increased Reliability: The absence of wire bonds in Multilayer Flip Chip Substrate reduces the risk of failure due to wire bond fatigue, enhancing the overall reliability of the packaged device.

Manufacturing Process of Multilayer Flip Chip Substrate

Process Flow: From Substrate Preparation to Flip Chip Bonding

1. Substrate Preparation: The process begins with the preparation of the base substrate, which involves selecting and cleaning the substrate material, such as FR-4 or polyimide.

2. Build-Up Layer Formation: Multiple build-up layers are then created on the base substrate using processes like thin film deposition, photolithography, and etching. These layers provide the necessary interconnects and routing for electrical connections.

3. Conductive Traces Patterning: Copper traces are patterned on the build-up layers using photolithography and etching techniques to establish electrical connections between components.

4. Solder Mask Application: A solder mask is applied to the substrate to protect the conductive traces and define areas for component placement and soldering.

5. Surface Finish: Surface finishes such as electroless nickel immersion gold (ENIG) or solder are applied to facilitate soldering and ensure good electrical contact.

6. Flip Chip Die Attachment: The Flip Chip die is then attached to the substrate using solder bumps or conductive adhesives. This process may involve precision placement equipment and controlled heating to achieve proper alignment and bonding.

Material Selection: Introduction to Common Materials

1. Substrate Material: Common substrate materials for Multilayer Flip Chip Substrate include FR-4, polyimide, and ceramic materials. These materials offer good mechanical properties, thermal stability, and electrical insulation.

2. Build-Up Layer Material: High-density interconnect (HDI) materials such as thin films of copper are commonly used for the build-up layers. These materials provide high conductivity and enable fine-line patterning for dense interconnects.

3. Conductive Traces Material: Copper is the most common material used for conductive traces due to its excellent electrical conductivity and compatibility with standard manufacturing processes.

4. Solder Mask Material: Epoxy-based solder masks are commonly used to protect the conductive traces and provide insulation. They offer good adhesion to the substrate and are resistant to soldering temperatures.

5. Surface Finish Material: Surface finishes like ENIG or solder provide a stable and reliable surface for soldering components onto the substrate. ENIG offers excellent corrosion resistance and solderability, while solder provides a low-cost option with good solder wetting properties.

Key Process Parameters and Control

1. Layer Thickness and Uniformity: Control of the thickness and uniformity of each layer is critical to ensure proper electrical performance and reliability.

2. Alignment and Registration: Precise alignment and registration of layers and components are essential to maintain electrical connectivity and signal integrity.

3. Solder Bump Formation: Control of solder bump size, shape, and placement is crucial for achieving reliable Flip Chip bonding and electrical connections.

4. Temperature and Heating Profiles: Optimal temperature and heating profiles during soldering processes are necessary to prevent defects such as voids, cracks, and delamination.

5. Quality Control and Testing: Comprehensive quality control measures, including visual inspection, electrical testing, and reliability testing, are implemented throughout the manufacturing process to ensure the final product meets performance and reliability requirements.

Application Areas of Multilayer Flip Chip Substrate

Communication and Network Equipment

Multilayer Flip Chip Substrate finds extensive use in communication and network equipment due to its high-density interconnects and superior electrical performance. It is employed in the manufacturing of routers, switches, base stations, and optical transceivers. The compact size and reliable connectivity provided by Multilayer Flip Chip Substrate enable the development of high-speed and high-bandwidth communication devices, essential for modern telecommunications infrastructure.

Automotive Electronics

In the automotive industry, Multilayer Flip Chip Substrate plays a crucial role in enabling the integration of advanced electronic systems for vehicle control, safety, and infotainment. It is utilized in applications such as engine control units (ECUs), advanced driver-assistance systems (ADAS), vehicle-to-vehicle (V2V) communication modules, and entertainment systems. The high reliability and compact design of Multilayer Flip Chip Substrate make it ideal for automotive applications where space constraints and harsh operating environments are common.

Industrial Control and Automation

Multilayer Flip Chip Substrate is widely employed in industrial control and automation systems to enable precise and efficient control of manufacturing processes and equipment. It is used in programmable logic controllers (PLCs), motion control systems, industrial robots, and sensor interfaces. The high-density interconnects and low signal delay provided by Multilayer Flip Chip Substrate contribute to the performance and reliability of industrial automation systems, enhancing productivity and reducing downtime.

Other Industry Application Cases

Apart from the aforementioned sectors, Multilayer Flip Chip Substrate finds application in various other industries, including:

– Medical Devices: In medical electronics, Multilayer Flip Chip Substrate is utilized in devices such as diagnostic equipment, patient monitoring systems, and implantable devices, where compact size and reliable performance are critical.

– Consumer Electronics: Multilayer Flip Chip Substrate is used in consumer electronics products such as smartphones, tablets, wearables, and gaming consoles, enabling compact designs and high-performance features.

– Aerospace and Defense: In aerospace and defense applications, Multilayer Flip Chip Substrate is employed in avionics systems, radar systems, navigation equipment, and unmanned aerial vehicles (UAVs), where reliability, ruggedness, and high-performance are essential.

Overall, Multilayer Flip Chip Substrate plays a pivotal role in enabling the development of advanced electronic systems across a wide range of industries, driving innovation and enhancing performance in various applications.

Future Prospects

Prospects for Technological Development and Market Application of Multilayer Flip Chip Substrate

The future of Multilayer Flip Chip Substrate is promising, driven by ongoing technological advancements and the increasing demand for high-performance electronic systems. Key prospects include:

1. Miniaturization and Integration: With the continuous push for miniaturization, Multilayer Flip Chip Substrate will continue to evolve to support the integration of more components in smaller form factors. This trend is particularly significant in applications such as wearables, IoT devices, and embedded systems.

2. High-Frequency Applications: As the demand for high-frequency communication and data processing increases, Multilayer Flip Chip Substrate will play a crucial role in enabling high-speed interconnects and signal integrity. Applications such as 5G infrastructure, data centers, and high-speed computing will benefit from the advancements in Multilayer Flip Chip Substrate technology.

3. Reliability and Durability: The focus on reliability and durability will drive the development of advanced materials and manufacturing processes for Multilayer Flip Chip Substrate. This includes improvements in solder bump technology, substrate materials, and thermal management techniques to enhance the reliability of electronic systems, especially in harsh operating environments such as automotive and aerospace applications.

4. Emerging Applications: Multilayer Flip Chip Substrate will find new applications in emerging fields such as artificial intelligence (AI), machine learning, autonomous vehicles, and augmented reality (AR)/virtual reality (VR). These applications require high-performance computing, low-latency communication, and compact designs, making Multilayer Flip Chip Substrate an essential component for their development.

5. Market Expansion: The expanding market for electronic devices across various industries, including automotive, healthcare, consumer electronics, and industrial automation, will drive the demand for Multilayer Flip Chip Substrate. As the adoption of advanced electronic systems increases globally, the market for Multilayer Flip Chip Substrate is expected to grow significantly.

Possible Technological Trends and Innovative Directions

Several technological trends and innovative directions are likely to shape the future of Multilayer Flip Chip Substrate:

1. Advanced Packaging Technologies: The integration of Multilayer Flip Chip Substrate with advanced packaging technologies such as system-in-package (SiP), 3D packaging, and fan-out wafer-level packaging (FOWLP) will enable further miniaturization and performance enhancements.

2. Embedded Die Technologies: The development of embedded die technologies, where semiconductor dies are directly embedded within the substrate, will offer new opportunities for compact and highly integrated electronic systems.

3. Heterogeneous Integration: Heterogeneous integration, which involves combining different types of components, such as sensors, MEMS devices, and RF modules, on the same substrate, will drive innovation in Multilayer Flip Chip Substrate design and manufacturing.

4. Advanced Materials: The use of advanced materials such as organic substrates with higher thermal conductivity, low-loss dielectric materials, and novel solder alloys will enable the development of Multilayer Flip Chip Substrate with enhanced electrical and thermal performance.

5. System-Level Optimization: The focus on system-level optimization, including co-design of Multilayer Flip Chip Substrate with semiconductor devices and packaging technologies, will lead to improved overall system performance, energy efficiency, and reliability.

Overall, the future of Multilayer Flip Chip Substrate is characterized by continuous innovation, driven by the need for higher performance, reliability, and miniaturization in electronic systems across various industries.

FAQs about Multilayer Flip Chip Substrate Manufacturer

The substrate of the flip chip package is typically a rigid or flexible material that serves as the foundation for mounting the semiconductor die and providing electrical connections. Common substrate materials include FR-4, polyimide, and ceramic.

The material used for flip chip bonding is typically solder or conductive adhesive. Solder bumps or balls are commonly used for flip chip bonding, where the solder material is deposited onto the bonding pads of the semiconductor die and then reflowed to form a permanent connection with the substrate.

In semiconductor manufacturing, the substrate refers to the base material on which semiconductor devices are fabricated. It is usually made of a semiconductor material such as silicon or gallium arsenide, on which layers of dopants and metal interconnects are deposited to create integrated circuits.

The main difference between wire bonding and flip chip packaging lies in how the semiconductor die is connected to the substrate or package. In wire bonding, thin wires are used to establish electrical connections between the bonding pads on the semiconductor die and the bonding pads on the substrate. In flip chip packaging, the semiconductor die is flipped upside down and directly bonded to the substrate or package using solder bumps or balls, eliminating the need for wire bonds. This results in shorter interconnect lengths, higher interconnection densities, and improved electrical performance compared to wire bonding.