Mastering the Art: Ceramic Substrates in Electronics

Ceramic Substrates & Components Ltd (CSC Ltd) is a leading provider of high-quality ceramic substrates and components tailored to meet the demands of diverse industries. With a focus on precision engineering and advanced materials, CSC Ltd offers a comprehensive range of products, including ceramic bushes, standoff insulators, and machinable ceramics.

In today’s rapidly evolving technological landscape, ceramic substrates and components play a pivotal role, particularly in electronics. These materials offer exceptional thermal and electrical properties, making them indispensable for applications requiring reliability, durability, and performance. From aerospace to telecommunications, ceramic substrates and components from CSC Ltd are trusted for their quality and versatility, driving innovation and progress across various sectors.

Understanding Ceramic Substrates

Definition and Significance of Ceramic Substrates:

Ceramic substrates are solid materials used as a base or support for electronic components and circuits. They are made from ceramic materials like alumina, aluminum nitride, or silicon carbide, known for their excellent thermal conductivity, electrical insulation, and mechanical strength. Ceramic substrates serve as robust foundations for electronic assemblies, providing structural support while efficiently dissipating heat generated during operation.

Properties and Advantages of Ceramic Substrates:

Ceramic substrates offer several advantages over traditional materials such as FR4 or metal substrates. These include:

– High Thermal Conductivity: Ceramic substrates efficiently dissipate heat, preventing overheating of electronic components and ensuring long-term reliability.

– Excellent Electrical Insulation: They possess high dielectric strength, preventing electrical leakage and enabling the reliable operation of sensitive electronic circuits.

– Mechanical Strength: Ceramic substrates are rigid and durable, withstanding mechanical stresses and environmental conditions, making them ideal for harsh operating environments.

– Compatibility with High-Frequency Signals: Ceramic substrates exhibit low signal loss, making them suitable for high-frequency applications like RF and microwave circuits.

– Chemical and Corrosion Resistance: They are resistant to chemical corrosion, ensuring the longevity of electronic assemblies in corrosive environments.

Common Applications of Ceramic Substrates in Electronic Devices:

Ceramic substrates find widespread use in various electronic devices, including:

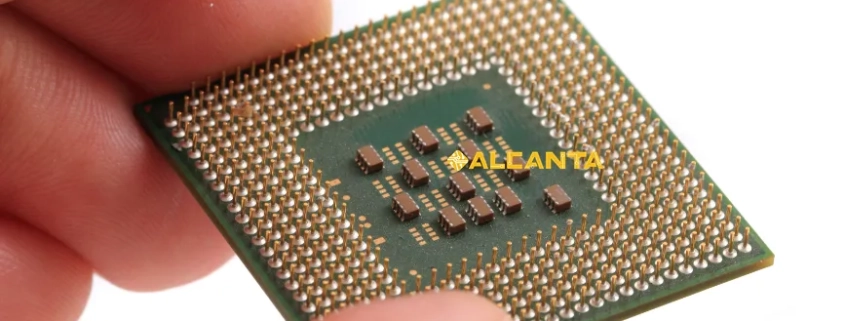

– Integrated Circuits (ICs) and Microprocessors: Ceramic substrates provide the structural foundation for ICs and microprocessors, facilitating efficient heat dissipation and electrical insulation.

– Light Emitting Diodes (LEDs): Ceramic substrates serve as mounting bases for LEDs, enabling thermal management and prolonging LED lifespan.

– Power Modules: They are used in power modules for inverters, converters, and motor drives, ensuring reliable performance and thermal stability.

– Sensor Packages: Ceramic substrates are utilized in sensor packages for applications such as automotive, industrial, and medical devices, ensuring accurate sensing and measurement.

– Radio Frequency (RF) and Microwave Devices: Ceramic substrates are integral to RF and microwave circuits, providing stable electrical performance at high frequencies.

In essence, ceramic substrates are essential components in electronic devices, offering a combination of thermal management, electrical insulation, and mechanical robustness critical for modern electronics.

Exploring Ceramic Components

Overview of Ceramic Components offered by CSC Ltd:

Ceramic Substrates & Components Ltd (CSC Ltd) specializes in providing a diverse array of ceramic components designed to meet the needs of various industries. These components are meticulously engineered using advanced ceramic materials, ensuring superior performance, durability, and reliability. CSC Ltd’s product range includes but is not limited to:

1. Ceramic Bushes: These are cylindrical components designed to provide support, insulation, and protection in mechanical and electrical applications. CSC Ltd offers ceramic bushes in various sizes, shapes, and compositions to suit different requirements.

2. Standoff Insulators: Ceramic standoff insulators are used to electrically isolate components or assemblies from mounting surfaces, ensuring safety and preventing electrical shorts. CSC Ltd offers standoff insulators with precise dimensions and high dielectric strength for optimal performance.

3. Machinable Ceramics: CSC Ltd also provides machinable ceramic materials that offer the versatility of conventional machining techniques while retaining the desirable properties of ceramics. These materials can be machined into complex shapes, making them ideal for custom applications.

Types of Ceramic Components:

Ceramic components offered by CSC Ltd encompass a wide range of products, including:

– Ceramic Bushes: Used in bearings, seals, and insulating applications.

– Standoff Insulators: Essential for electrical insulation and mounting in electronic assemblies.

– Ceramic Substrates: Providing the foundation for electronic circuits and components.

– Insulating Tubes: Used in high-temperature environments for electrical insulation.

– Terminal Blocks: Facilitating electrical connections in various devices.

– Spacer Beads: Ensuring precise spacing and alignment in electronic assemblies.

– Custom Ceramic Components: Tailored solutions to meet specific customer requirements.

Importance of Ceramic Components:

Ceramic components play a crucial role in enhancing the performance and reliability of systems across diverse applications. Their significance lies in:

– Thermal Management: Ceramic components offer excellent thermal conductivity, dissipating heat efficiently and preventing thermal-induced failures.

– Electrical Insulation: They provide high dielectric strength, ensuring reliable electrical insulation and preventing short circuits.

– Mechanical Stability: Ceramic components exhibit high mechanical strength and dimensional stability, withstanding harsh operating conditions and mechanical stresses.

– Corrosion Resistance: They are resistant to chemical corrosion, ensuring longevity and reliability in corrosive environments.

– Customization: Ceramic components can be tailored to meet specific design requirements, offering versatility and flexibility in application.

In summary, ceramic components offered by CSC Ltd are integral to various industries, providing essential functionality, reliability, and performance enhancements in a wide range of applications.

Machinable Ceramic: A Specialized Product

Definition and Features of Machinable Ceramic:

Machinable ceramic refers to a type of ceramic material that possesses the unique property of being easily machined or shaped using conventional machining techniques such as milling, turning, drilling, and grinding. Unlike traditional ceramics that are brittle and challenging to work with, machinable ceramics offer exceptional machinability while retaining desirable properties such as high temperature resistance, electrical insulation, and chemical inertness. This versatility in machining allows for the creation of complex shapes and precise dimensions, making machinable ceramic ideal for custom applications.

Applications and Benefits of Machinable Ceramic in Industrial Settings:

Machinable ceramic finds a wide range of applications across various industries due to its unique combination of properties and ease of machining. Some common applications include:

– Precision Components: Machinable ceramic is used to fabricate precision components such as fixtures, tooling, and wear-resistant parts in manufacturing processes.

– Insulating Components: It is employed in the production of insulating components for electrical and electronic applications, including insulators, spacers, and bushings.

– High-Temperature Environments: Machinable ceramic is utilized in high-temperature environments where traditional materials may fail, such as furnace components, thermocouple protection tubes, and heat exchangers.

– Chemical Processing: It is suitable for use in chemical processing equipment, including valves, seals, and pump components, due to its corrosion resistance and inertness to harsh chemicals.

The benefits of machinable ceramic in industrial settings include:

– Customization: Machinable ceramic can be tailored to meet specific design requirements, allowing for the creation of custom components optimized for performance and functionality.

– Dimensional Stability: Machinable ceramic exhibits excellent dimensional stability even under extreme temperatures, ensuring consistent performance over time.

– Chemical Resistance: It is resistant to corrosion and chemical attack, making it suitable for use in aggressive environments where other materials may degrade.

– Thermal Insulation: Machinable ceramic provides effective thermal insulation, reducing heat transfer and minimizing thermal expansion in high-temperature applications.

How CSC Ltd’s Machinable Ceramic Products Stand Out in the Market:

CSC Ltd’s machinable ceramic products stand out in the market due to their exceptional quality, precision, and versatility. Leveraging advanced manufacturing techniques and superior raw materials, CSC Ltd offers machinable ceramic products that exceed industry standards in terms of performance and reliability. Additionally, CSC Ltd provides comprehensive support and expertise in product selection, customization, and application engineering, ensuring that customers receive tailored solutions that meet their specific requirements. With a commitment to innovation and customer satisfaction, CSC Ltd continues to be a trusted partner for industries seeking high-quality machinable ceramic solutions.

Ceramic Bushes: Essential Components

Introduction to Ceramic Bushes and Their Significance:

Ceramic bushes are cylindrical components with a central hole used to reduce friction and wear between two moving parts or to insulate electrical conductors. They are typically made from advanced ceramic materials such as alumina or zirconia, known for their excellent mechanical properties, wear resistance, and high temperature tolerance. Ceramic bushes play a critical role in various industrial applications where conventional materials may fail due to factors like high loads, extreme temperatures, or corrosive environments.

Variants of Ceramic Bushes Available at CSC Ltd:

CSC Ltd offers a diverse range of ceramic bushes tailored to meet the specific needs of different applications. Some variants include:

– Alumina Ceramic Bushes: Known for their high strength, abrasion resistance, and thermal stability, alumina ceramic bushes are ideal for demanding applications in industries such as automotive, aerospace, and manufacturing.

– Zirconia Ceramic Bushes: Zirconia ceramic bushes offer exceptional wear resistance and toughness, making them suitable for high-load applications, precision machinery, and medical equipment.

– Silicon Nitride Ceramic Bushes: Silicon nitride ceramic bushes exhibit superior thermal shock resistance, corrosion resistance, and low thermal expansion, making them suitable for use in extreme environments such as semiconductor processing and chemical processing.

Use Cases and Industries Where Ceramic Bushes Play a Crucial Role:

Ceramic bushes are essential components in various industries where reliable performance and longevity are paramount. Some common use cases include:

– Automotive Industry: Ceramic bushes are used in automotive engines, transmissions, and suspension systems to reduce friction, improve durability, and enhance fuel efficiency.

– Electronics and Semiconductor Manufacturing: Ceramic bushes serve as insulating components in electrical connectors, switches, and semiconductor processing equipment, ensuring reliable electrical isolation and thermal management.

– Medical Devices: Ceramic bushes are utilized in medical devices such as surgical instruments, dental tools, and prosthetic implants for their biocompatibility, wear resistance, and sterilization capabilities.

– Aerospace and Defense: Ceramic bushes are employed in aircraft engines, landing gear systems, and missile guidance systems for their lightweight design, high temperature resistance, and resistance to abrasion and corrosion.

– Industrial Machinery: Ceramic bushes are integral to various industrial machinery and equipment, including pumps, valves, bearings, and textile machinery, where they help reduce maintenance, extend service life, and improve operational efficiency.

In summary, ceramic bushes are indispensable components in numerous industries, providing superior performance, reliability, and durability in demanding applications where traditional materials may fall short. With a wide range of variants available, CSC Ltd’s ceramic bushes offer tailored solutions to meet the diverse needs of customers across different sectors.

Ceramic Standoff Insulators: Ensuring Electrical Safety

Importance of Ceramic Standoff Insulators in Electrical Systems:

Ceramic standoff insulators serve a critical role in electrical systems by providing a barrier between conductive components, preventing electrical current from flowing where it shouldn’t. They are essential for maintaining electrical safety, particularly in high-voltage applications, by effectively isolating conductors and components, thereby reducing the risk of electrical shocks, short circuits, and fires. Without proper insulation provided by standoff insulators, electrical systems would be prone to malfunctions, breakdowns, and safety hazards.

Unique Properties of Ceramic Standoff Insulators and Their Benefits:

Ceramic standoff insulators offer several unique properties that make them ideal for electrical insulation:

– High Dielectric Strength: Ceramic materials exhibit high dielectric strength, allowing them to withstand high voltages without conducting electricity.

– Thermal Stability: Ceramic standoff insulators maintain their electrical and mechanical properties across a wide range of temperatures, ensuring reliability in both extreme cold and heat.

– Corrosion Resistance: They are resistant to corrosion and chemical degradation, making them suitable for use in harsh environments where exposure to moisture, chemicals, and pollutants is common.

– Mechanical Strength: Ceramic standoff insulators possess excellent mechanical strength, providing structural support and withstanding mechanical stresses such as vibration and mechanical shock.

The benefits of ceramic standoff insulators include enhanced electrical safety, reliability, and longevity of electrical systems, making them indispensable components in various industries.

CSC Ltd’s Offerings in Ceramic Standoff Insulators and Their Applications:

CSC Ltd offers a diverse range of ceramic standoff insulators designed to meet the stringent requirements of different applications. These insulators are used in a wide range of industries, including:

– Electronics: Ceramic standoff insulators are employed in electronic circuit boards, power supplies, and electrical enclosures to provide insulation and support for components.

– Telecommunications: They are utilized in antennas, transmission towers, and communication equipment to maintain electrical isolation and prevent signal interference.

– Power Distribution: Ceramic standoff insulators are used in power distribution systems, switchgear, and transformers to insulate conductors and components, ensuring safe and reliable operation.

– Industrial Equipment: They find applications in various industrial equipment such as motors, generators, and machinery, where electrical isolation and insulation are essential for preventing equipment damage and ensuring worker safety.

CSC Ltd’s ceramic standoff insulators are manufactured to the highest quality standards, ensuring consistent performance and reliability in demanding applications. With a commitment to innovation and customer satisfaction, CSC Ltd continues to provide customized solutions tailored to meet the specific needs of its clients across diverse industries.

Ceramic Substrates in Electronics

Understanding the Role of Ceramic Substrates in Electronic Package Design:

Ceramic substrates play a crucial role in electronic package design by providing a stable and reliable foundation for electronic components. They serve as the structural backbone onto which various electronic elements, such as integrated circuits (ICs), resistors, capacitors, and conductive traces, are mounted and interconnected. Ceramic substrates facilitate the efficient transfer of heat away from sensitive components, ensuring optimal thermal management and preventing overheating. Moreover, they offer excellent electrical insulation, protecting components from short circuits and electrical interference. The design flexibility of ceramic substrates allows for the creation of intricate circuit layouts and miniaturized electronic devices, enabling advancements in technology and product innovation.

Specific Ceramics Used in Electronic Substrate Packages:

Several ceramics are commonly used in electronic substrate packages, each offering unique properties tailored to specific application requirements. Some of the most frequently utilized ceramics include:

– Alumina (Al2O3): Known for its high thermal conductivity, excellent mechanical strength, and electrical insulation properties, alumina is widely used in electronic substrates for its reliability and versatility.

– Aluminum Nitride (AlN): AlN exhibits superior thermal conductivity compared to alumina, making it ideal for applications requiring enhanced heat dissipation, such as power electronics and high-power LED packaging.

– Silicon Carbide (SiC): SiC substrates offer exceptional thermal conductivity, chemical inertness, and high-temperature stability, making them suitable for harsh operating environments and demanding applications like automotive and aerospace electronics.

Advantages of Using Ceramic Substrates in Electronic Applications:

The utilization of ceramic substrates in electronic applications offers several advantages, including:

– Excellent Thermal Management: Ceramic substrates efficiently dissipate heat generated by electronic components, ensuring reliable operation and prolonging component lifespan.

– High Electrical Insulation: Ceramic substrates provide superior electrical insulation, preventing leakage currents and minimizing signal interference in electronic circuits.

– Mechanical Stability: Ceramics exhibit high mechanical strength and dimensional stability, withstanding mechanical stresses and environmental factors such as vibration, humidity, and temperature fluctuations.

– Miniaturization and Integration: Ceramic substrates enable the miniaturization and integration of electronic components, allowing for compact and lightweight electronic devices with increased functionality and performance.

– Chemical and Corrosion Resistance: Ceramics are resistant to chemical corrosion and environmental degradation, ensuring the longevity and reliability of electronic assemblies in harsh operating conditions.

In summary, ceramic substrates play a vital role in electronic packaging by providing thermal management, electrical insulation, and mechanical stability, contributing to the advancement and innovation of electronic devices across various industries.

FAQs about ceramic substrates & components ltd

A ceramic substrate is a solid material layer that serves as a foundation or support for electronic components and circuits. It is typically made of ceramic materials such as alumina (Al2O3), aluminum nitride (AlN), or silicon carbide (SiC). Ceramic substrates provide electrical insulation, thermal management, and mechanical support for electronic devices.

The ceramics commonly used in electronic substrate packages include alumina (Al2O3), aluminum nitride (AlN), and silicon carbide (SiC). These ceramics offer excellent electrical insulation, thermal conductivity, and mechanical strength, making them ideal for electronic applications where reliability and performance are crucial.

In electronics, various ceramics are used depending on the specific requirements of the application. Common ceramics used include alumina (Al2O3), aluminum nitride (AlN), silicon carbide (SiC), zirconia (ZrO2), and beryllia (BeO). These ceramics are employed in electronic components such as substrates, insulators, capacitors, resistors, and packaging materials due to their unique properties such as high electrical insulation, thermal conductivity, and mechanical strength.

Ceramic substrates are typically made of ceramic materials such as alumina (Al2O3), aluminum nitride (AlN), or silicon carbide (SiC). These ceramics are chosen for their excellent electrical insulation, thermal conductivity, and mechanical properties. The specific composition and manufacturing process may vary depending on the desired properties and applications of the ceramic substrate.